THE STUDY OF GUANIL UREA SULFATE AS A MODIFIER OF FIBREBOARD

Abstract

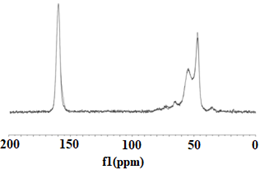

Fiberboards are producing of vegetable raw materials and urea-formaldehyde glues. The necessity to bind formaldehyde led to the search for modifiers that are capable to reduce the toxicity of wood boards without impairment of their physico-mechanical properties. It was researched how guanylurea sulfate influences on some process, which are occur during the formation of wood boards. The salts were synthesized at molar ratios of cyanoguanidine : sulfuric acid from 1 : 0.1 to 1 : 0.5 and their effects on the technological parameters of the glue were investigated. It was found that in combination with the urea-formaldehyde resin guanylurea sulfate sworn GUS-0.5 synthesized at a 1 : 0.5 molar ratio is most suitable as it accelerates hardening of the resin without negative influence on other standard parameters. Physicochemical tests and 13C solid-state NMR spectroscopy have shown that upon injection into the glue GUS-0.5 reacts with the functional groups of the urea-formaldehyde oligomer while embedding into the structure of the curing resin. At temperatures of hot pressing of wood boards in case of injection into the composition separately from the glue GUS-0.5 is subject to thermal transformations with the formation of ammonia. It’s shown that the properties of fiberboards depend on the method of injection of the modifier into the composition. To effectively reduce toxicity without impairment of their physico-mechanical properties should be used a combined method of using the modifier when one half is injected into the glue and the other half separately.

Downloads

Metrics

References

Shalashov A.P. Sostoyaniye i perspektivy razvitiya proizvodstva drevesnykh plit: sbornik dokladov 21-oy mezh-dunarodnoy nauchno-prakticheskoy konferentsii. [The state and prospects of development of the production of wood-based panels: a collection of reports of the 21st international scientific-practical conference]. Balabanovo, 2018, pp. 3–11. (in Russ.).

Varankina G.S., Chubinskiy A.N. Formirovaniye nizkotoksichnykh kleyenykh drevesnykh materialov. [Formation of low toxic glued wood materials]. St. Petersburg., 2014, 148 p. (in Russ.).

Ogorodnikov S.K. Formal'degid. [Formaldehyde]. Leningrad, 1984, 280 p. (in Russ.).

Razin'kov Ye.M., Ishchenko T.L. Snizheniye toksichnosti drevesnykh plit i kleyenykh materialov: monografiya. [Reduc-tion of toxicity of wood-based panels and glued materials: monograph]. Saarbrken: Palmarium Academic Publishing, 2013, 168 p. (in Russ.).

Romanov N.M. Khimiya karbamido- i melaminoformal'degidnykh smol. [Chemistry of urea and melamine formaldehyde resins]. Moscow, 2016, 528 p. (in Russ.).

Roffael E. Vydeleniye formal'degida iz drevesnostruzhechnykh plit. [Formaldehyde emission from chipboard]. Ed. A.A. Elbert. Moscow, 1991, 160 p. (in Russ.).

Ivanov D.V., Leonovich A.A., Silicheva M.D. Sostoyaniye i perspektivy razvitiya proizvodstva drevesnykh plit: sbornik dokladov 21-oy mezh-dunarodnoy nauchno-prakticheskoy konferentsii. [The state and prospects of development of the production of wood-based panels: a collection of reports of the 21st international scientific-practical conference]. Bala-banovo, 2018, pp. 120–128. (in Russ.).

Leonovich A.A., Voytova T.N., Shpakovskiy V.G. Drevesnyye plity: teoriya i praktika: Materialy 18 Mezhdunarodnoy nauchno-prakticheskoy konferentsiya. [Wood plates: theory and practice: Materials of the 18th International Scientific Practical Conference]. St. Petersburg, 2015, pp. 33–40. (in Russ.).

Mayofis L.S. Khimiya i tekhnologiya khimiko-farmatsevticheskikh preparatov. [Chemistry and technology of chemical and pharmaceutical preparations]. Leningrad, 1964, 716 p. (in Russ.).

B'yukenen D. Tsianistyye soyedineniya i ikh analiz. [Cyanide compounds and their analysis]. Leningrad, 1933, 125 p. (in Russ.).

Patent 009912 (ЕАС). 28.04.2008. (in Russ.).

TU 6-06-12–88. Smola karbamidoformal'degidnaya KFMT-15. [Technical specifications 6-06-12–88. Carbamide for-maldehyde resin KFMT-15] URL: http://pkf-volga.ru/smola-karbamidoformaldegidnaya-kfmt-15. (in Russ.).

GOST 8420–74. Materialy lakokrasochnyye. Metody opredeleniya uslovnoy vyazkosti. [Government Standard 8420–74. Paint materials. Methods for determining the conditional viscosity.]. Moscow, 2004, 7 p. (in Russ.).

GOST 14231–88. Smoly karbamidoformal'degidnyye. Tekhnicheskiye usloviya. [Government Standard 14231–88. Urea-formaldehyde resins. Technical conditions.]. Moscow, 2003, 15 p. (in Russ.).

Kasterina T.N., Kalinina L.S. Khimicheskiye metody issledovaniya sinteticheskikh smol i plasticheskikh mass. [Chemical methods for the study of synthetic resins and plastics]. Moscow, 1963, 288 p. (in Russ.).

Kim M.G. Journal of Polymer Science. Part A, 1999, vol. 37, pp. 995–1007.

Rammon R.M. The Journal of Adhesion, 1986, vol. 19, pp. 115–135.

GOST 32274–2013. Plity drevesnyye monostrukturnyye. Tekhnicheskiye usloviya. [Government Standard 32274–2013. Monostructural wood plates. Technical conditions.]. Moscow, 2014, 12 p. (in Russ.).

GOST 10635–88. Plity drevesnostruzhechnyye. Metody opredeleniya prochnosti i modulya uprugosti pri izgibe. [Gov-ernment Standard 10635–88. Flake boards. Methods for determining the strength and modulus of elasticity in bending]. Moscow, 1991, 7 p. (in Russ.).

GOST 10636–88. Plity drevesnostruzhechnyye. Metody opredeleniya predela prochnosti pri rastyazhenii perpendikul-yarno plasti plity. [Government Standard 10636–88. Flake boards. Methods for determining the tensile strength perpen-dicular to the plate]. Moscow, 1990, 7 p. (in Russ.).

GOST 10634–88. Plity drevesnostruzhechnyye. Metody opredeleniya fizicheskikh svoystv. [Government Standard 10634–88. Flake boards. Methods for determining physical properties]. Moscow, 1991, 9 p. (in Russ.).

Vasil'yev V.V. Drevesnyye materialy: trebovanii i sertifikatsiya v Yevrope, Rossii i SSHA: sbornik nauchnykh trudov po itogam mezhdunarodnogo simpoziuma. [Wood materials: requirements and certification in Europe, Russia and the USA: a collection of scientific papers on the basis of the international symposium]. Balabanovo, 2016, pp. 85–87. (in Russ.).

Khartman K. Planirovaniye eksperimenta v issledovanii tekhnologicheskikh protsessov. [Planning an experiment in the study of technological processes]. Moscow, 1977, 552 p. (in Russ.).

Ivanov D.V., Leonovich A.A., Mazur A.S. Izvestiya Sankt-Peterburgskoy lesotekhnicheskoy akademii, 2018, issue 222, pp. 263–275. (in Russ.).

Virpsha Z., Bzhezin'skiy YA. Aminoplasty. [Aminoplasts]. Moscow, 1973, 344 p. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.