USAGE OF BI- AND POLYFUNCTIONAL COMPOUNDS AS AN ALTERNATIVE OF SYNTHETIC RESINS IN FI-BERBOARD TECHNOLOGY

UDC 674.817

Abstract

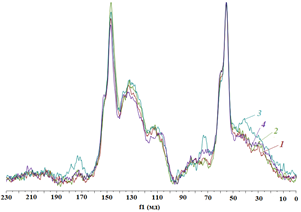

Due to the high chemical activity of its filler, fiberboard is a unique material, it's formation can be ensured by chemical reactions of wood components. However, under hot pressing modes, typical for dry-process boards, chemical reactions do not have time to go through to the required extent, which requires the use of special modifiers that enhance the activity of the wood fiber. Bi- and polyfunctional compounds - sucrose, carbamide, and citric acid - were investigated as modifiers. The lowest efficiency was shown by sucrose, which is not able to ensure the compliance of the physical and mechanical parameters of the fiberboards with the requirements of standards; The use of urea and citric acid makes it possible to produce fiberboards that are not inferior in their properties to materials from urea-formaldehyde resin. Using the methods of chemical and instrumental analysis (IR spectroscopy, solid-state 13C NMR spectroscopy), it was found that during hot pressing, urea and citric acid react with components of the wood cell wall. Urea decomposes during pressing with the formation of ammonia and isocyanic acid, which, in turn, provides interfiber interaction. During hot pressing, citric acid reacts with hydroxyl groups of cell wall components by the esterification mechanism. Using the example of citric acid, it was found that plates that meet the requirements of the TSN-30 standart can be made only with a pressing time of 0.4 min / mm of the fiberboard thickness, which exceeds the technology requirements by more than two times. To ensure the competitiveness of the selected modifiers with respect to existing synthetic resins, it is necessary to find ways to reduce the pressing time.

Downloads

Metrics

References

V'yunkov S.N. Tekhnologiya drevesnykh plit s ispol'zovaniyem svyazuyushchego na osnove zhidkogo stekla: avtoref. diss. ... kand. tekhn. nauk. [Technology of wood-based panels using a binder based on liquid glass: Ph.D. diss. ... cand. tech. Sciences]. St. Petersburg, 1999, 16 p. (in Russ.).

Enayati A.A., Sani F.R., Kavei F. Res. Dev. Material Sci. 2021, vol. 15(2), pp. 1662–1666. DOI: 10.31031/RDMS.2021.15.000856.

Li J., Fu W., Li F., Li D. Ferroelectrics, 2020, vol. 566(1), pp. 54–80. DOI: 10.1080/00150193.2020.1762430.

Pizzi A., Papadopoulos A.N., Policardi F. Polymers, 2020, vol. 12(5), 1115. DOI: 10.3390/polym12051115.

Shcherbakov A.S., Gamova I.A., Mel'nikova L.V. Tekhnologiya kompozitsionnykh drevesnykh materialov: uchebnoye posobiye dlya vuzov. [Technology of composite wood materials: textbook for universities]. Moscow, 1992, 192 p. (in Russ.).

Katrakov I.B., Markin V.I., Bazarnova N.G. Izvestiya altayskogo gosudarstvennogo universiteta, 2014, no. 3-1 (83), pp. 204–208. DOI: 10.14258/izvasu(2014)3.1-37. (in Russ.).

Katrakov I.B., Markin V.I., Kolosov P.V. Khimiya rastitel'nogo syr'ya, 2018, no. 3, pp. 251–260. DOI: 10.14258/jcprm.2018034338. (in Russ.).

Solechnik N.Ya. Proizvodstvo drevesno-voloknistykh plit. [Production of wood fiber boards]. Moscow, 1963, 338 p. (in Russ.).

Solov'yova T.V. Prevrashcheniya komponentov lignouglevodnoy matritsy v tekhnologii drevesnovoloknistykh plit: avtoref. diss. ... d-ra. tekhn. nauk. [Transformation of the components of the lignocarbohydrate matrix in the technology of fibreboards: Ph.D. diss. ... dr. tech. Sciences]. Minsk, 1998, 36 p. (in Russ.).

Ivanov D.V., Ryabinkov A.A., Orekhov Ye.V. Drevesnyye plity i fanera: teoriya i praktika: Vseros. nauch.-prakt. konf. [Wood boards and plywood: theory and practice: All-Russian scientific-practical conf.]. St. Petersburg, 2021, pp. 79–86. (in Russ.).

Yermolin V.N., Bayandin M.A., Kazitsin S.N., Namyatov A.V., Ostryakova V.A. Izvestiya vuzov. Lesnoy zhurnal, 2020, no. 3, pp. 151–158. DOI: 10.37482/0536-1036-2020-3-151-158. (in Russ.).

Gamova I.A. Issledovaniye i razrabotka sposoba polucheniya drevesnovoloknistykh plit i plastikov povy-shennoy prochnosti i vodostoykosti: diss. … kand. tekhn. nauk. [Research and development of a method for obtaining fiber-boards and plastics of increased strength and water resistance: diss. … cand. tech. Sciences]. Leningrad, 1968, 142 p. (in Russ.).

Tsarev G.I., Leonovich A.A. Izvestiya Sankt-Peterburgskoy lesotekhnicheskoy akademii, 1995, no. 161, pp. 169–180. (in Russ.).

Antov P., Savov V., Trichkov N., Krišt’ák L’., Réh R., Papadopoulos A.N., Taghiyari H.R., Pizzi A., Kunecová D., Pachikova M. Polymers, 2021, vol. 13, 639. DOI: 10.3390/polym13040639.

Antov P., Jivkov V., Savov V., Simeonova R., Yavorov N. Applied Sciences, 2020, vol. 10 (21), 7526. DOI: 10.3390/app10217526.

Savov V., Antov V. Drvna Industrija, 2020, vol. 71(2), pp. 157–162. DOI: 10.5552/drvind.2020.1968.

Leonovich A.A. Fiziko-khimicheskiye osnovy obrazovaniya drevesnykh plit. [Physical and chemical bases of formation of wood boards]. St. Petersburg, 2003, 192 p. (in Russ.).

Vasil'yev V.V. Drevesnyye materialy: trebovanii i sertifikatsiya v Yevrope, Rossii i SShA. Sbornik nauchnykh trudov po itogam mezhdu-narodnogo simpoziuma. [Wood materials: requirements and certification in Europe, Russia and the USA. Collection of scientific papers based on the results of the international symposium]. Balabanovovo, 2016, pp. 85–87. (in Russ.).

Obolenskaya A.V., Yel'nitskaya Z.P., Leonovich A.A. Laboratornyye raboty po khimii drevesiny i tsellyulozy: uchebnoye posobiye dlya vuzov. [Laboratory work on the chemistry of wood and cellulose: a textbook for universities]. Moscow, 1991, 320 p. (in Russ.).

Plity MDF tverdyye. [MDF boards, solid]. URL: http://service-group.ru/lot3116. (in Russ.).

Roffael E. Formaldehyde release from particleboard and other wood based panels. Kuala Lumpur, 1993, 281 p.

Vasil'yev A.V., Grinenko Ye.V., Shchukin A.O., Fedulina T.G. Infrakrasnaya spektroskopiya organicheskikh i pri-rodnykh soyedineniy: Uchebnoye posobiye. [Infrared Spectroscopy of Organic and Natural Compounds: Tutorial]. St. Petersburg, 2007, 54 p. (in Russ.).

Virpsha Z., Bzhezin'skiy Ya. Aminoplasty. [Aminoplasts]. Moscow, 1973, 344 p. (in Russ.).

Prech E., Byul'mann F., Affol'ter K. Opredeleniye stroyeniye organicheskikh soyedineniy. Tablitsy spektral'nykh dannykh. [Determination of the structure of organic compounds. Tables of spectral data]. Moscow, 2006, 438 p. (in Russ.).

Lignin and Lignans: advances in chemistry, ed. C. Heitner, D. Dimmel, J.A. Schmidt. CRC Press, Taylor & Francis Group, 2010, 629 p.

Kostryukov S.G., Petrov P.S., Masterova Yu.Yu., Idris T.D., Khamdamov S.S., Yunusov I.A., Kostryukov N.S. Khimiya rastitel'nogo syr'ya, 2021, no. 2, pp. 95–102. DOI: 10.14258/jcprm.2021028790. (in Russ.).

Yevstigneyev E.I., Yuzikhin O.S., Gurinov A.A., Ivanov A.Yu., Artamonova T.O., Khodorkovskiy M.A., Bessono-va Ye.A., Vasil'yev A.V. Zhurnal prikladnoy khimii, 2015, vol. 88, no. 5, pp. 1175–1183. (in Russ.).

Levanova S.V., Krasnykh Ye.L., Moiseyeva S.V., Safronov S.P., Glazko I.L. Izvestiya vysshikh uchebnykh zavedeniy. Seriya: Khimiya i khimicheskaya tekhnologiya, 2021, vol. 64, no. 6, pp. 69–75. DOI: 10.6060/ivkkt.20216406.6369. (in Russ.).

Ando D., Umemura K. Polymers, 2021, vol. 13, 58. DOI: 10.3390/polym13010058.

Pereira D.C., Nakamura A.P.D., Brum S.S. Drvna industrija: Scientific journal of wood technology, 2020, vol. 71, no. 3, pp. 232–245. DOI: 10.5552/drvind.2020.1917.

Cahyono T.D., Syahidah. 14th Pacific Rim Bio-Based Composites Symposium. IOP Conference Series: Materials Sci-ence and Engineering, 2019, vol. 593, 012009. DOI: 10.1088/1757-899X/593/1/012009.

Copyright (c) 2022 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.