GRINDING OF FIBROUS SEMI-FINISHED PRODUCTS AS A MECHANOCHEMICAL PROCESS. MATHEMATICAL MODELING

UDC 676.024.61

Abstract

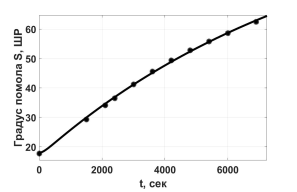

It is known that the process of grinding fibrous semi-finished products proceeds in the form of four successive stages, accompanied by complex processes of fibrillation and hydration of fibers subjected to mechanical action. The development of these processes over time determines the dynamics of changes in cellulose fiber, which ultimately leads to the formation of the necessary paper-forming properties. The paper shows that the representation of the grinding of fibrous semi-finished products as a mechanochemical process makes it possible to formulate a mathematical model of the grinding dynamics based on the principles of formal kinetics. The latter makes it possible to single out the stages of the milling process in the form of a standard kinetic mechanism of successively occurring reactions. The corresponding model is presented as a system of ordinary differential equations with constant coefficients, the solution of which presents no fundamental difficulties. Since it is not the degree of destruction that is determined experimentally, but the degree of grinding, it is proposed to present the relationship between these values as a power series with a limitation in the form of a linear approximation. However, due to the large dimension, the parametric identification of the model has fundamental difficulties. The paper proposes a reduction method that allows overcoming the problem. The corresponding parameters are identified by comparing the model and the array of experimental data. The presented approach makes it possible to obtain an adequate closed mathematical description of the dynamics of grinding fibrous semi-finished products.

Downloads

Metrics

References

Ostwald W. Lehrbuch der allgemeinen Chemie Bd. 2 Stöchiometrie. Leipzig: Engelmann, 1981, 1163 p.

Boldyrev V.V. Fundamental'nyye osnovy mekhanicheskoy aktivatsii, mekhanosinteza i mekhanokhimicheskikh tekhnologiy. [Fundamentals of mechanical activation, mechanosynthesis and mechanochemical technologies]. Novosi-birsk, 2009, 343 p. (in Russ.).

Baramboym N.K. Mekhanokhimiya vysokomolekulyarnykh soyedineniy. [Mechanochemistry of high-molecular com-pounds]. Moscow, 1971, 364 p. (in Russ.).

Butyagin P.Yu. Uspekhi khimii, 1971, vol. 40, no. 11, pp. 1935–1959. (in Russ.).

Kryazhev A.M. Sb. plenarnykh dokl. 5-y mezhdunar. konf. PAP-FOR-98. [Sat. plenary reports 5th Int. conf. PAP-FOR-98]. St. Petersburg, 1998, pp. 189–198. (in Russ.).

Osovskaya I.I., Baykova V.S., Poltoratskiy G.M. Khimiya Rastitel'nogo Syr'ya, 2015, no. 1, pp. 175–180. (in Russ.).

Ivanov S.N. Tekhnologiya bumagi. 3 izdaniye. [Paper technology. 3rd edition]. Moscow, 2006, 384 p. (in Russ.).

Paulapuro H. Papermaking science and technology. Book 8. Papermaking: part 1. Stock preparation and wet end. Ota-niemi, 2000. 461 p.

Batchelor W.J. Nordic pulp & paper research journal, 1999, vol. 14, no. 4, pp. 285–286.

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva. T. 2. Chast' pervaya. Tekhnologiya proizvodstva i obrabotki bumagi i kartona. [Pulp and paper production technology. Vol. 2. Part one. Technology of production and processing of paper and cardboard]. St. Petersburg, 2005, pp. 36–37. (in Russ.).

Kalinin N.N. Zhurn. prikl. Khimii, 1984, no. 11, pp. 2538–2542. (in Russ.).

Kryazhev A.M., Shpakov F.V., Glazunov A.I. Tsellyuloza. Bumaga. Karton, 1998, no. 3-4, pp. 22–23. (in Russ.).

Antonova N.I., Malinovskaya G.K., Yeremeyeva I.I., Sebeleva G.V. Bumazhnaya promyshlennost', 1987, no. 4, p. 8. (in Russ.).

Goncharov B.H., Legotskiy C.C. Razmalyvayushcheye oborudovaniye i podgotovka bumazhnoy massy. [Grinding equipment and pulp preparation]. Moscow, 1990, pp. 6–7. (in Russ.).

Alashkevich Yu.D., Ushakov A.V., Kozhukhov V.A., Kovalev V.I. Khimiya Rastitel'nogo Syr'ya, 2020, no. 4, pp. 315–329. (in Russ.).

Alashkevich Yu.D., Konyukhova V.V., Yurtayeva L.V. Khvoynyye boreal'nyye zony, 2018, vol. 36, no. 5, pp. 371–374. (in Russ.).

Chen L.-h., He B.-h., Zhan H.-y., Lu Q.-h. J. Fujian Coll. Forest, 2001, vol. 21, no. 2, pp. 116–119.

Alikin V.P. Fiziko-mekhanicheskiye svoystva prirodnykh volokon, izmeneniye etikh svoystv v protsessakh razmola i su-shki. [Physico-mechanical properties of natural fibers, changes in these properties during grinding and drying process-es]. Moscow, 1969, 140 p. (in Russ.).

Ivanov S.N. Bumazhnaya promyshlennost', 1967, no. 11, pp. 11–13.

Hietanen S., Ebeling K. Paper ja Puu, 1990, vol. 72, no. 2, pp. 156–169.

Konrad O., Czechowski J. Ann. Warsaw Agr. Univ. Forest and Wood Technol., 2006, no. 59, pp. 132–136.

Legotskiy S.S., Laptev L.N. Razmol bumazhnoy massy. [Pulp grinding]. Moscow, 1981, 89 p. (in Russ.).

Karlsson M., Malashenko A. 86th Annual Meeting of PAPTAC (Pulp and Paper Technical Association of Canada). Montreal, 2000, pp. 273–280.

Steenberg B. Svensk Papperstidning, 1963, vol. 66, no. 22, pp. 933–939.

Eyring G., Lin S.G., Lin S.M. Osnovy khimicheskoy kinetiki. [Fundamentals of chemical kinetics]. Moscow, 1983, 522 p. (in Russ.).

Copyright (c) 2023 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.