INFLUENCE OF THE PATTERN OF THE COMBINED GRINDING SET OF THE DISC MILL ON INDIVIDUAL PAPER-FORMING PROPERTIES OF FIBROUS SEMI-FINISHED PRODUCTS AND THE PHYSICAL AND MECHANICAL CHARACTERISTICS OF THE FINISHED PRODUCT

UDC 676.15

Abstract

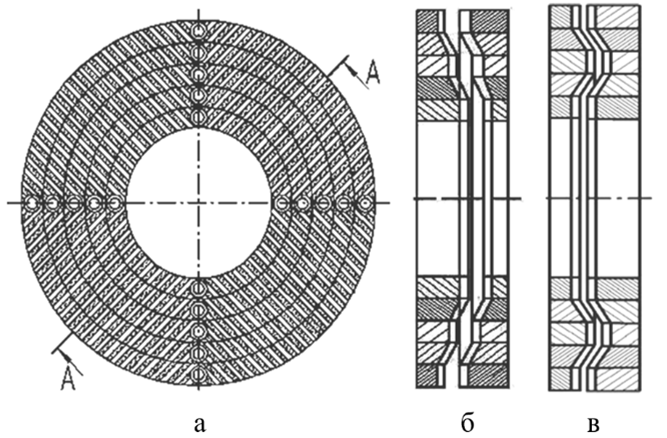

The improvement of the process of grinding fibrous semi-finished products in pulp and paper production is caused by a reduction in the raw material base, requirements for the quality of finished products, as well as the desire to reduce production energy costs. Changing the grinding parameters allows you to change the properties and characteristics of the resulting materials in a wide range. The main controlled parameters of the grinding process are the gap between the rotor and stator disks, the rotor speed, the concentration of the fibrous mass. One of the important parameters of the grinding process is also the design of the grinding set. The article considers the influence of various configurations of cavities of the combined grinding set of a disc mill on the properties of the fibrous mass and finished paper castings. Individual paper-forming properties were evaluated, including the increase in the degree of grinding of the fibrous mass and the length of the fiber, as well as the physical and mechanical characteristics of the finished castings, which include the breaking length of the paper, the number of double folds and the tear resistance index. The grinding was carried out on a semi-industrial disc mill using a combined grinding set. For comparison, wavy and conical grinding cavities with straight unidirectional knives were selected. It was revealed that the wave-shaped grinding cavity has higher quality indicators in comparison with the conical grinding cavity by the nature of the impact on the fibrous mass.

Downloads

Metrics

References

Fraser J., Breslau C. Pulp and Paper. Canada, Ontario, 2000, pp. 271–273.

Alashkevich Yu.D., Kovalev V.I., Nabiyeva A.A. Vliyaniye risunka garnitury na protsess razmola voloknistykh polufabrikatov: monografiya v 2-kh chastyakh. [The influence of the headset pattern on the process of grinding fibrous semi-finished products: a monograph in 2 parts]. Krasnoyarsk, 2010, part. 1, 168 p. (in Russ.).

Chistova N.G. Razmol drevesnovoloknistoy massy na promyshlennykh ustanovkakh pri proizvodstve DVP: dis. ... kand. tekhn. nauk. [Grinding wood fiber mass in industrial installations for the production of fiberboard: dis. ...cand. tech. Sci.]. Krasnoyarsk, 2000, 193 p. (in Russ.).

Bogoyavlenskiy I.I. Tekhnologiya bumagi. [Paper technology]. Moscow-Leningrad, 1946, vol. 1, 258 p. (in Russ.).

Smit S. Ratsional'naya teoriya rolla. [Rational theory of roll]. Berlin, 1922, 105 p. (in Russ.).

Suterlend M. Trudy tekhnicheskoy assotsiatsii, 1936, vol. 19, pp. 175–187. (in Russ.).

Viduell G., Suterlend M. Trudy tekhnicheskoy assotsiatsii, 1936, vol. 19, pp. 162–175. (in Russ.).

Ivanov S.N. Tekhnologiya bumagi. [Paper technology]. Moscow, 2006, 696 p. (in Russ.).

Steenberg B. Svensk Papperstidning, 1963, vol. 66, pp. 933–939.

Nabiyeva A.A. Otsenka vliyaniya i sovershenstvovaniya tekhnologicheskikh parametrov nozhevykh razmalyvayush-chikh mashin: dis. … kand. tekhn. nauk. [Assessing the influence and improvement of technological parameters of knife grinding machines: dis. ...cand. tech. Sci.]. Krasnoyarsk, 2004, 156 p. (in Russ.).

Kovalev V.I. Razmol voloknistykh polufabrikatov pri razlichnom kharaktere postroyeniya risunka nozhevoy garnitury: dis. … kand. tekhn. nauk. [Grinding of fibrous semi-finished products with different types of knife design: dis. ...cand. tech. Sci.]. Krasnoyarsk, 2007, 209 p. (in Russ.).

Vititnev A.Yu. Sovershenstvovaniye protsessa razmola voloknistykh polufabrikatov v proizvodstve dreves-novoloknistykh plit: dis. ... kand. tekhn. nauk. [Improving the process of grinding fibrous semi-finished products in the production of wood-fiber boards: dis. ...cand. tech. Sci.]. Krasnoyarsk, 2019, 152 p. (in Russ.).

Shurkina V.I. Sovershenstvovaniye nozhevogo razmola voloknistykh rastitel'nykh polimerov v tsellyulozno-bumazhnom proizvodstve: avtoref. dis. … kand. tekhn. nauk. [Improving knife grinding of fibrous plant polymers in pulp and paper production: abstract of thesis. dis. ...cand. tech. Sci.]. Krasnoyarsk, 2016, 22 p.

Alashkevich Yu.D. Osnovy teorii gidrodinamicheskoy obrabotki voloknistykh materialov v razmol'nykh mashinakh: dis. … dokt. tekhn. nauk. Leningrad, 1980, 334 p. (in Russ.).

Shurkina V.I., Marchenko R.A., Alashkevich Yu.D. IOP Conference Series: Materials Science and Engineering, 2019, vol. 467, 012002. DOI 10.1088/1757-899X/467/1/012002.

Kanavellis R. Teoreticheskiye osnovy inzhenernykh raschetov, 1968, vol. 90, no. 3, pp. 39–48. (in Russ.).

Goncharov V.N., Gauze A.A., Alikin V.P. Mashiny dlya rospuska i beznozhevogo razmola bumazhnoy massy. [Ma-chines for dissolving and knifeless grinding of paper pulp]. Leningrad, 1979, 106 p. (in Russ.).

GOST R 56847-2015. Protsessy proizvodstva tsellyulozy. Normativy obrazovaniya otkhodov. [GOST R 56847-2015. Pulp production processes. Waste generation standards]. Moscow, 2016, 20 p. (in Russ.).

Patent 2314380 C1 (RU). 10.01.2008. (in Russ.).

Petrova A.A., Voronin I.A., Alashkevich Yu.D. Lesnoy i khimicheskiy kompleksy – problemy i resheniya: sbornik ma-terialov po itogam Vserossiyskoy nauchno-prakticheskoy konferentsii. [Forestry and chemical complexes - problems and solutions: collection of materials based on the results of the All-Russian scientific and practical conference]. Kras-noyarsk, 2021, pp. 390–393. (in Russ.).

GOST ISO 1924-1-96. Bumaga i karton. Opredeleniye prochnosti pri rastyazhenii. Ch. 1. Metod nagruzheniya s postoyannoy skorost'yu. [GOST ISO 1924-1-96. Paper and cardboard. Determination of tensile strength. Part 1. Con-stant speed loading method]. Minsk, 2000, 10 p. (in Russ.).

GOST 13525.2-80. Polufabrikaty voloknistyye, bumaga i karton. Metod opredeleniya prochnosti na izlom pri mnog-okratnykh peregibakh. [GOST 13525.2-80. Semi-finished fibrous products, paper and cardboard. Method for deter-mining fracture strength after repeated bending]. Moscow, 2007, 4 p. (in Russ.).

GOST 13525.3-97. Polufabrikaty voloknistyye i bumaga. Metod opredeleniya soprotivleniya razdiraniyu (metod El'mendorfa). [GOST 13525.3-97. Semi-finished fiber products and paper. Method for determining tear resistance (Elmendorf method)]. Moscow, 2007, 8 p. (in Russ.).

Copyright (c) 2023 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.