PEROXIDE CELLULOSE FROM WHEAT AND HEMP STEMS

UDC 676.166

Abstract

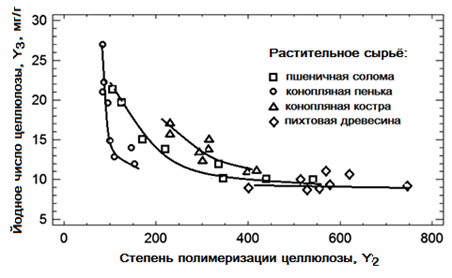

The wheat steams (Triticum sh.), hemp and shive from the technical cannabis (Cannabis sativa), wood of Siberia fir (Abies sibirica) was processed with the sodium hydrate (concentration NaOH 1 g-mol/dm3, liquid module 6, temperature 93 °C, length 2 hours), washed with water and delignificated by the “hydrogen peroxide – sulfuric acid – water” solution (initial concentration of the acetic acid 6 g-mol/dm3, hydrogen peroxide – also 6 g-mol/dm3 , sulfuric acid – 1.5% (mass.), liquid module 6, temperature of the isothermal process 93 °C, length 210 minutes). Simultaneously the same vegetable raw material was delignificated without alkaline preprocessing and without sulfuric acid catalyst at the cooking. The purpose of the study – estimation of the influence named factors on output and characteristic of the cellulose. Mathematical processing is performed with the methods of the cluster and dispersing analysis. Alkaline preprocessing has brought to reduction of the output and degree polymerization and to increase the iodine number only to celluloses from wheat straw. The additive catalytic amount of the sulfuric acid to cooking solution brought to the reduction of the output and degree polymerization and to increase the iodine number of the cellulose from all type used one-year vegetable raw. Under approaching choice technological cooking conditions it is possible reception of the product with the characteristics microcrystalline celluloses (the degree polymerization not above 300, iodine number not less 10 mg/g) with one-stage peroxide cooking without alkaline preprocessing and catalyst.

Downloads

Metrics

References

Pen R.Z., Karetnikova N.V., Shapiro I.L. Khimiya Rastitel'nogo Syr'ya, 2020, no. 4, pp. 329–347. DOI: 10.14258/jcprm.2020048119. (in Russ.).

Pen R.Z., Shapiro I.L., Karetnikova N.V., Marchenko R.A. Peroksidnaya tsellyuloza iz odnoletnikh rasteniy. [Cellulose peroxide from annual plants]. Krasnoyarsk, 2022, 144 p. (in Russ.).

Zia-ullah Khokhar, Syed Q., Nadeem M., Baig S., Irfan M., Gul I., Tipu I., Aslam S., Samra Z.Q., Athar M.A. World Applied Sciences Journal, 2010, no. 11(12), pp. 1524–1530.

Chen Y.M., Wang Y., Wan J.Q., Ma Y.W. Cellulose, 2010, vol. 17, no. 2, pp. 329–338.

Krupin V.I., Dem'yanovskaya N.V., Kudryashov V.N. Tsellyuloza. Bumaga. Karton, 2010, no. 3, pp. 50–51. (in Russ.).

Kuznetsov B.N., Danilov V.G., Sudakova I.G., Yatsenkova O.V., Garyntseva N.I., Ibragimova Ye.F. Khimiya Ras-titel'nogo Syr'ya, 2009, no. 4, pp. 39–44. (in Russ.).

Kuznetsov B.N., Sudakova I.G., Garyntseva N.V., Ivanchenko N.M. Khimiya v interesakh ustoychivogo razvitiya, 2011, no. 19, pp. 527–533. (in Russ.).

Singh S., Dutt D., Tyagi C.H. BioResources, 2011, vol. 6, no. 1, pp. 154–177.

Yimmon B.M., Gogate P.R., Horvath M. Ultrasonics Sonochemistry, 2012, vol. 19, pp. 984–993.

Liu Z., Cao Y., Yao H., Wu S. BioResuorces, 2013, vol. 8, pp. 1306–1319.

Wel T., Jiang C., Zhi-qi B., Qi Z., Chang L., Yue G. J. Harbin Univ. Commer. Natur. Sci. Ed., 2015, no. 4, pp. 458–459.

Vurasko A.V., Driker B.N. Tsellyuloza iz odnoletnikh rasteniy. Okislitel'no-organosol'ventnaya varka. [Cellulose from annual plants. Oxidative-organosolv cooking]. Saarbrücken, 2004, 129 p. (in Russ.).

Pen R.Z., Shapiro I.L., Karetnikova N.V. Khimiya Rastitel'nogo Syr'ya, 2022, no. 2, pp. 299–305. DOI: 10.14258.jcprm.20220210688. (in Russ.).

Pen R., Karetnikova N., Shapiro I. Peroksidnaya tsellyuloza. Delignifikatsiya rastitel'nogo syr'ya peroksosoyedineni-yami. [Cellulose peroxide. Delignification of plant raw materials with peroxo compounds]. Saarbrücken, 2013, 245 p. (in Russ.).

Pen R.Z., Shapiro I.L., Marchenko R.A. Problemy mekhaniki tsellyulozno-bumazhnykh materialov: materialy VI Mezhdunarodnoy nauchno-tekhnicheskoy konferentsii. [Problems of mechanics of pulp and paper materials: materials of the VI International Scientific and Technical Conference]. Arkhangelsk, 2021, pp. 333–338. (in Russ.).

Belopukhova Yu.B. Tret'ye Vserossiyskoye soveshchaniye konoplevodov. [III All-Russian meeting of hemp breeders]. Moscow, 2019. URL: https://www.rosflaxhemp.ru/zhurnal/informacija-i-analiz.html/id/3265. (in Russ.).

Obolenskaya A.V., Yel'nitskaya Z.P., Leonovich A.A. Laboratornyye raboty po khimii drevesiny i tsellyulozy. [Labora-tory work on the chemistry of wood and cellulose]. Moscow, 1991, 320 p. (in Russ.).

Pen R.Z., Pen V.R. Statisticheskiye metody matematicheskogo modelirovaniya, analiza i optimizatsii tekhnologicheskikh protsessov. 2-ye izd., stereotipnoye. [Statistical methods of mathematical modeling, analysis and optimization of techno-logical processes. 2nd ed., stereotypical]. St. Petersburg, 2002, 308 p. (in Russ.).

Pen R.Z., Karetnikova N.V., Chendylova L.V. Statisticheskiye metody analiza protsessov tsellyulozno-bumazhnogo proizvodstva. [Statistical methods for analyzing pulp and paper production processes]. Krasnoyarsk, 2021, 156 p. (in Russ.).

Dubrov A.M., Mkhitaryan V.S., Troshin L.I. Mnogomernyye statisticheskiye metody. [Multivariate statistical methods]. М., 2003, 352 p. (in Russ.).

Copyright (c) 2023 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.