XYLITOL PRODUCTION FROM XYLOSE OVER ZIRCONIA-DOPED SILICA SBA-15 SUPPORTED RUTHENIUM CATALYSTS

UDC 547.455.526, 544.478

Abstract

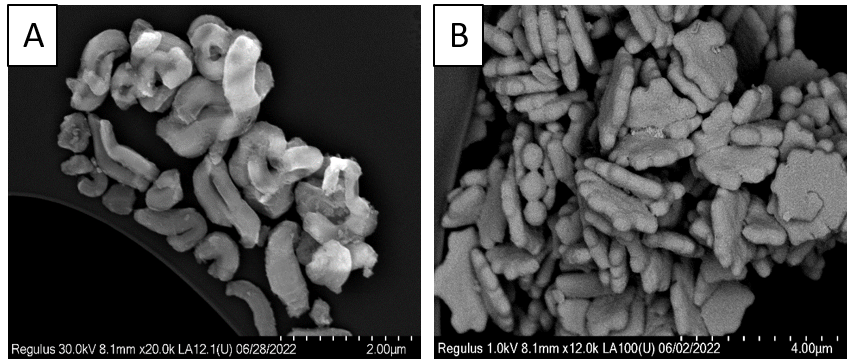

Xylitol is an important product of xylan valorization — the main hemicellulose of birch and aspen wood. Xylitol is obtained by direct hydrogenation of xylose. In present study, the xylose was obtained by acid hydrolysis of birch wood xylan. The industrial catalyst for the xylitol production process is Raney nickel. Pyrophoricity, tendency to sintering, Ni leaching and contamination of the product are actual problems of its use. We have developed new supported ruthenium catalysts based on mesoporous silicate SBA-15 doped with zirconia. The proposed method of modification of SBA-15 by doping with zirconia improves the hydrothermal stability. The deposited Ru is present in the form of highly dispersed RuO2 particles and is distributed evenly. The catalysts are stable, safe and environmentally friendly. Their high catalytic activity allows the process to be carried out in very mild conditions – in pure water at 70 °C and a pressure of 5.5 MPa H2. While the catalysts provide 96-99% selectivity for xylitol. The introduction of the developed catalysts into the xylitol production might reduce the product purification cost of and the process energy consumption, thereby improving ecological and economic indicators of deep chemical processing of plant raw materials.

Downloads

Metrics

References

Levdansky V.A., Kondrasenko A.A., Levdansky A.V., Kuznetsov B.N. Journal of Siberian Federal University. Chemistry, 2021, vol. 14, no. 3, pp. 325–336. DOI: 10.17516/1998-2836-0241.

Jin X., Hu Z., Wu S., Song T., Yue F., Xiang Z. Carbohydrate polymers, 2019, vol. 215, pp. 235–245. DOI: 10.1016/j.carbpol.2019.03.092.

Kuznetsov B.N., Sudakova I.G., Chudina A.I., Garyntseva N.V., Kazachenko A.S., Skripnikov A.M., Malyar Y.N., Ivanov I.P. Biomass Conversion and Biorefinery, 2022. DOI: 10.1007/s13399-022-02498-x.

Ly K.A., Milgrom P., Rothen M. Pediatric dentistry, 2006, vol. 28, no. 2, pp. 154–163.

Ylikahri R. Advances in Food Research. Academic Press, 1979, pp. 159–180.

Schiweck H.B., Albert & Vogel, Roland & Schwarz, Eugen & K, MARKWART & Lüssem, Bernd & Moser, Matthias & Peters, Siegfried & C, DUSAUTOIS & Lefranc-Millot, Catherine & A, CLEMENT. Sugar Alcohols // Ullmann's Encyclopedia of Industrial ChemistryEdition: 7th Edition Chapter: Sugar Alcohols. 2011. DOI: 10.1002/14356007.a25_413.pub2.

Delgado Arcaño Y., Valmaña García O.D., Mandelli D., Carvalho W.A., Magalhães Pontes L.A. Catalysis Today, 2020, vol. 344, pp. 2–14. DOI: 10.1016/j.cattod.2018.07.060.

García B., Orozco-Saumell A., López Granados M., Moreno J., Iglesias J. ACS Sustainable Chemistry & Engineering, 2021, vol. 9, no. 44, pp. 14857–14867. DOI: 10.1021/acssuschemeng.1c04957.

Cheng S., Martínez-Monteagudo S.I. Asia-Pacific Journal of Chemical Engineering, 2019, vol. 14, no. 1. e2275. DOI: 10.1002/apj.2275.

Hoffer B.W., Crezee E., Mooijman P.R.M., van Langeveld A.D., Kapteijn F., Moulijn J. A. Catalysis Today, 2003, vol. 79–80, pp. 35–41. DOI: 10.1016/S0920-5861(03)00040-3.

Michel C., Gallezot P. ACS Catalysis, 2015, vol. 5, no. 7, pp. 4130–4132. DOI: 10.1021/acscatal.5b00707.

Ahmed M.J., Hameed B.H. Journal of the Taiwan Institute of Chemical Engineers, 2019, vol. 96, pp. 341–352. DOI: 10.1016/j.jtice.2018.11.028.

Kusserow B., Schimpf S., Claus P. Advanced Synthesis & Catalysis, 2003, vol. 345, no. 1-2, pp. 289–299. DOI: 10.1002/adsc.200390024.

Singh S., Kumar R., Setiabudi H.D., Nanda S., Vo D.-V.N. Applied Catalysis A: General, 2018, vol. 559, pp. 57–74. DOI: 10.1016/j.apcata.2018.04.015.

Kozlova S.A., Kirik S.D. Microporous and Mesoporous Materials, 2010, vol. 133, no. 1-3, pp. 124–133. DOI: 10.1016/j.micromeso.2010.04.024.

Sabbaghi A., Lam F. L. Y., Hu X. Journal of Molecular Catalysis A: Chemical, 2015, vol. 409, pp. 69–78. DOI: 10.1016/j.molcata.2015.08.005.

Gromov N., Medvedeva T., Panchenko V., Taran O., Timofeeva M., Parmon V. Catalysis in Industry, 2023, vol. 15, no. 1, pp. 87–98. DOI: 10.1134/S2070050421010050.

Gromov N.V., Medvedeva T.B., Rodikova Y.A., Timofeeva M.N., Panchenko V.N., Taran O.P., Kozhevnikov I.V., Parmon V.N. Bioresource Technology, 2021, vol. 319, pp. 124122. DOI: 10.1016/j.biortech.2020.124122.

Zhao D., Huo Q., Feng J., Chmelka B.F., Stucky G.D. Journal of the American Chemical Society, 1998, vol. 120, no. 24, pp. 6024–6036. DOI: 10.1021/ja974025i.

Thunyaratchatanon C., Luengnaruemitchai A., Chaisuwan T., Chollacoop N., Chen S.-Y., Yoshimura Y. Microporous and Mesoporous Materials, 2017, vol. 253, pp. 18–28.

Miroshnikova A.V., Sychev V.V., Tarabanko V.E., Kazachenko A.S., Skripnikov A.M., Eremina A.O., Kosivtsov Y., Taran O.P. International Journal of Molecular Sciences, 2023, vol. 24, no. 14, pp. 11337.

Ruiz-Matute A.I., Hernández-Hernández O., Rodríguez-Sánchez S., Sanz M. L., Martínez-Castro I. Journal of chromatography. B. Analytical technologies in the biomedical and life sciences, 2011, vol. 879, no. 17-18, pp. 1226–1240. DOI: 10.1016/j.jchromb.2010.11.013.

Huo L., Wang T., Xuan K., Li L., Pu Y., Li C., Qiao C., Yang H., Bai Y. Catalysts, 2021, vol. 11, no. 6, pp. 710. DOI: 10.3390/catal11060710.

Kwon N.H., Kim M., Jin X., Lim J., Kim I.Y., Lee N.-S., Kim H., Hwang S.-J. NPG Asia Materials, 2018, vol. 10, no. 7, pp. 659–669. DOI: 10.1038/s41427-018-0060-3.

Baudel H., Abreu C. d., Zaror C. Journal of Chemical Technology & Biotechnology, 2005, vol. 80, no. 2, pp. 230–233. DOI: 10.1002/jctb.1155.

Vilcocq L., Paez A., Freitas V. D., Veyre L., Fongarland P., Philippe R. RSC advances, 2021, vol. 11, no. 62, pp. 39387–39398. DOI: 10.1039/D1RA08193D.

Delgado-Arcaño Y., Mandelli D., Carvalho W.A., Pontes L.A.M. Waste and Biomass Valorization, 2021, vol. 12, no. 9, pp. 5109–5120. DOI: 10.1007/s12649-021-01348-7.

Copyright (c) 2023 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.