COMPARATIVE STUDIES OF PHYSIC-CHEMICAL PROPERTIES AND STRUCTURE OF COTTON CELLULOSE AND ITS MODIFIED FORMS

Abstract

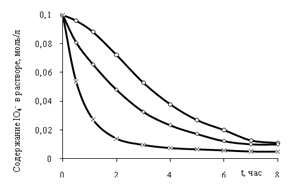

Comparative studies of the physicochemical properties and structures of cotton cellulose, microcrystalline cellulose, and nanocellulose were carried out using IR, NMR spectroscopy, X-ray diffraction, thermal analysis in order to identify the dependence "particle size - structure - properties". It was revealed that in the series “cotton cellulose – microcrystalline cellulose – nanocellulose” the degree of polymerization decreases (1200, 230, 110 respectively), the degree of crystallinity increases (66%, 72%, 83% respectively). The IR spectra of microcrystalline cellulose and nanocellulose are characterized by sharp peaks (in the range 1000–1500 cm–1) compared with cotton cellulose. The amount of bound water in gels of microcrystalline cellulose and nanocellulose increases with decreasing particle size, the degree of stability of colloidal systems increases with the transition from microcrystalline cellulose to nanocellulose. Nanocellulose and microcrystalline cellulose have relatively smaller mass loss and relatively large temperature ranges of intensive decomposition and their thermal stability is higher than cotton cellulose. It was found that the periodate oxidation rate of nanocellulose is higher than that of microcrystalline cellulose and cotton cellulose. It was established that microcrystalline cellulose is quantitatively susceptible to periodate oxidation in 7–8 hours, and nanocellulose in 0.5–1 hour.

Downloads

Metrics

References

Gal'braykh L.S. Sorosovskiy obrazovatel'nyy zhurnal, 1996, no. 11, pp. 47–53. (in Russ.).

Braun B., Dorgan J.R. Biomacromolecules, 2009, no. 10, pр. 334–341, DOI: 10.1021/bm8011117.

Hasani M., Cranston E.D., Westman G., Gray D.G. Soft Matter, 2008, no. 4, pр. 2238–2244, DOI: 10.1039/b806789a.

Morandi G., Heath L., Thielemans W. Langmuir, 2009, no. 25, pр. 8280–8286, DOI: 10.1021/la900452a.

Morais J.P.S., Rosa M.F., Filho M.M.S., Nascimento L.D., Nascimento D.M., Cassales A.R. Carbohydrate Polymers, 2013, no. 91, pp. 229–235, DOI: 10.1016/j.carbpol.2012.08.010.

Autlov S.A., Bazarnova N.G., Kushnir Ye.Yu. Khimiya rastitel'nogo syr'ya, 2013, no. 3, pp. 33–41, DOI: 10.14258/jcprm.1303033. (in Russ.).

Atakhanov A.A., Tikhonovetskaya A.D., Nabiyev D.S., Rashidova S.Sh. Khimiya rastitel'nogo syr'ya, 2004, no. 1, pp. 23–26. (in Russ.).

Atakhanov A.A., Tikhonovetskaya A.D., Nabiyev D.S., Sarymsakov A.A., Rashidova S.Sh. Farmatsevticheskiy zhur-nal, 2010, no. 4, pp. 66–72. (in Russ.).

Atakhanov A.A., Turdikulov I.Kh., Kuzieva M. Uzbek chemical journal, 2017, special issue, pp. 200–211.

GOST 9105-74. Tsellyuloza. Metod opredeleniya sredney stepeni polimerizatsii. [GOST 9105-74. Cellulose. Method for determining the average degree of polymerization]. Moscow, 1998, 6 p. (in Russ.).

Rogovin Z.A. Khimiya tsellyulozy. [Cellulose Chemistry]. Moscow, 1972, 520 p. (in Russ.).

Kargarzadeh H., Ahmad I., Abdullah I., Dufresne A., Zainudin S.Y., Sheltami R.M. Cellulose, 2012, no. 19, pр. 855–866, DOI: 10.1007/s10570-012-9684-6.

Atakhanov A.A., Yunusov M.Yu., Sarymsakov A.A., Rashidova S.Sh. Khimiya rastitel'nogo syr'ya, 2012, no. 3, pp. 45–48. (in Russ.).

Pittman R.A., Tripp V.W. Polym. Sci, 1970, no. 8, pр. 969–976.

Yanul' N.A., Kukushkina Yu.A., Sokolov V.V., Kravchik A.Ye., Kirsh Yu.E. Zhurnal prikladnoy khimii, 1999, vol. 72, no. 12, pp. 2037–2041. (in Russ.).

Frolova S.V., Kuvshinova L.A., Bugayeva A.Yu., Kuchin A.V. Khimiya rastitel'nogo syr'ya, 2011, no. 1. pp. 43–46. (in Russ.).

Karlivan V.P. Metody issledovaniya tsellyulozy. [Cellulose research methods]. Riga, 1981, 257 p. (in Russ.).

Basch A., Lewin M.J. J. Polymer Sci, 1973, vol. 11, no. 12, pp.3071–3093.

Sarymsakov A.A. Sredne- i nizkozameshchennaya karboksimetiltsellyuloza – polucheniye, svoystva i primeneniye. [Medium and low substituted carboxymethyl cellulose – production, properties and application]. Tashkent, 2005, 180 p. (in Russ.).

Nazhimutdinov Sh., Sarymsakov A.A., Usmanov Kh.U. Cellulose chemistry and Technology, 1975, vol. 7, no. 2, pр. 197–208.

Copyright (c) 2019 Khimiia rastitel'nogo syr'ia (Chemistry of plant raw material)

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.