IMPROVING THE TECHNOLOGY OF PRODUCING CELLULOSE OXIDATION-ORGANOSOLVENT WAY OF NON-WOOD PLANT MATERIALS

Abstract

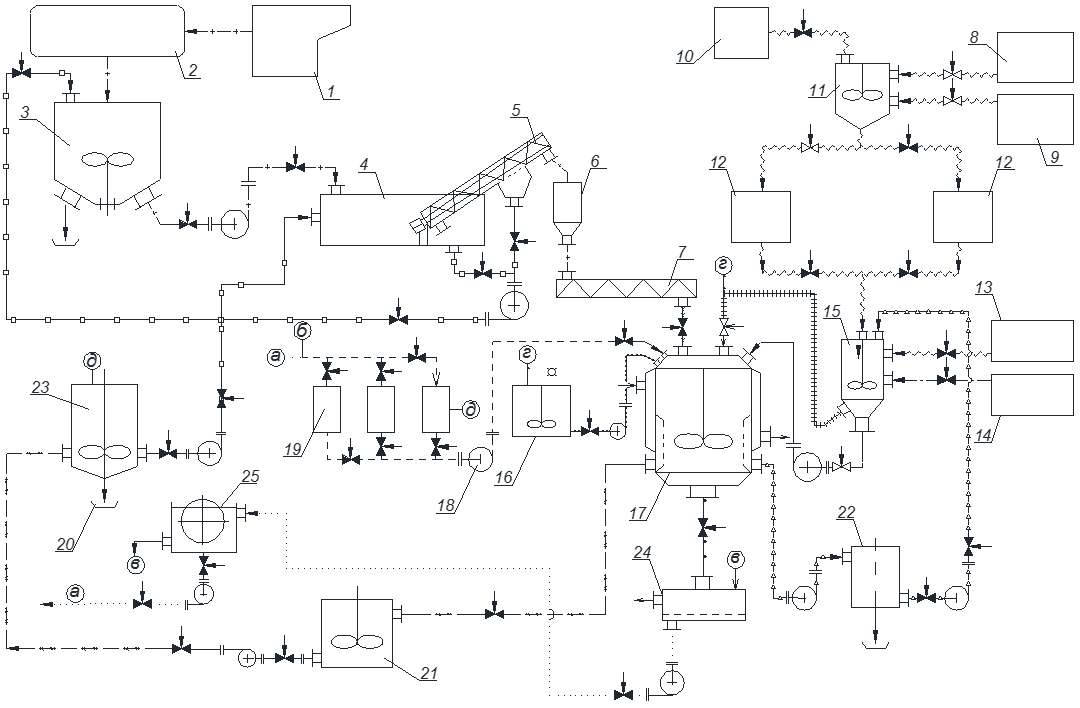

An improved process flow diagram for the production of cellulose by oxidation-organosolvent method from non-wood vegetable raw materials with pre-alkaline treatment and recovery of the spent cooking solution has been developed. It is shown that it is possible to obtain technical cellulose with the desired properties with repeated use of the spent cooking solution, which allows to reduce the consumption of acetic acid and fresh water by two and 1.7 times, respectively. The scheme includes the following stages: preparation of raw materials; preparation of the cooking composition and alkaline solution, alkaline treatment, cooking and washing of cellulose, recovery of the spent cooking solution, neutralization of the spent alkaline solution and the use of contaminated water. When implementing the flowcharts are formed by the following types of contaminated water: water for rinsing plant material circulates through the first and second steps of adding water with catalyst; circulating the water from flushing technical pulp in three stages – the washing water from the first washing stage is directed to the Converter; the washing water from the second stage washing sent to the first stage of the wash technical cellulose; the third step of the rinsing water is fed from the drum filter with the addition of fresh water; the concentration of sodium hydroxide in the spent alkaline solution is 1.75 %. In the neutralizer, weakly acidic water with a concentration of acetic acid of 0.83% and sodium acetate with a concentration of 2.5% is formed; weakly acidic water from the neutralizer is fed to the first stage of washing plant raw materials. Fresh water is used for the preparation of balanced peracetic acid, alkaline solution and the third stage of technical cellulose washing. Solid waste is formed in the hydraulic separator during washing of vegetable raw materials; in the tank of the spent cooking solution in the form of a precipitate from zero fiber; in the neutralizer, the washed precipitate can be used as an anti-frost additive for concrete. It is proposed to use reactor and neutralizer as the main technological equipment.

Downloads

Metrics

References

Polyutov A.A., Pen R.Z., Byvshev A.V. Tekhnologiya tsellyulozy ekologicheski chistoye proizvodstvo. [Cellulose tech-nology environmentally friendly production]. Krasnoyarsk, 2012, 294 p. (in Russ.).

Pen R.Z., Shapiro I.L., Leonova M.O. Problemy khimiko-lesnogo kompleksa. [Problems of the chemical forest complex]. Krasnoyarsk, 1995, part. 2, p. 80. (in Russ.).

Patlasov V.P., Trofimov A.N., Kaplun L.D., Chuprova V.A., Mikhaylov A.I. Khimiya rastitel'nogo syr'ya, 2000, no. 2, pp. 29–35. (in Russ.).

Vurasko А.V., Glukhikh V.V., Simonova E.I., Minakova A.R. Proceedings of the Annual Scientific International Con-ference, Nizhniy Tagil, Russia, May 4. 2018, pp. 7–16.

Siegl S. Natural pulping – update and progress, 2002, pp. 237–249.

Pen R.Z., Karetnikova N.V. Khimiya rastitel'nogo syr'ya, 2005, no. 3, pp. 61–73. (in Russ.).

Levdanskiy V.A., Kuznetsov B.N. Khimiya rastitel'nogo syr'ya, 2014, no. 2, pp. 35–40. DOI: 10.14258/jcprm.1402035. (in Russ.).

Levdanskiy V.A., Levdanskiy A.V., Kuznetsov B.N. Khimiya: zhurnal Sibirskogo federal'nogo universiteta, 2014, no. 7, pp. 63–70. (in Russ.).

Vurasko A.V., Simonova Ye.I., Minakova A.R. Izvestiya Sankt-Peterburgskoy lesotekhnicheskoy akademii, 2018, no. 223, pp. 228–248. (in Russ.).

Vurasko A.V., Minakova A.R., Driker B.N., Sivakov V.P., Kosacheva A.M. Khimiya rastitel'nogo syr'ya, 2010, no. 2, pp. 165–168. (in Russ.).

Simonova Ye.I. Polucheniye i svoystva sorbtsionnykh materialov na osnove tekhnicheskoy tsellyulozy iz nedrevesno-go rastitel'nogo syr'ya: dissertatsiya kandidata tekhnicheskikh nauk. [Obtaining and properties of sorption materials based on technical cellulose from non-woody plant materials: the dissertation of the candidate of technical sciences]. Yekaterin-burg, 2018, 169 p. (in Russ.).

Patent 2200155 (RU), 2003. (in Russ.).

Patent 2312946 (RU), 2007. (in Russ.).

Patent 2321696 (RU), 2008. (in Russ.).

Leonova M.O. Okislitel'naya delignifikatsiya drevesiny v sisteme «peroksid vodoroda – uksusnaya kislota – voda – peroksokompleksy perekhodnykh metallov»: dissertatsiya kandidata khimicheskikh nauk. [Oxidative delignification of wood in the system "hydrogen peroxide - acetic acid - water - peroxo complexes of transition metals": the dissertation of the candidate of chemical sciences]. Krasnoyarsk, 1996, 179 p. (in Russ.).

Tarakanov O.V., Belyakova Ye.A., Gorshkov V.I. Regional'naya arkhitektura i stroitel'stvo, 2014, no. 1, pp. 53–58. (in Russ.).

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva: v 3 t. T. 1. Syr'ye i proizvodstvo polufabrikatov. CH. 2. Proizvod-stvo polufabrikatov. [Technology of pulp and paper production: in 3 vol. Vol. 1. Raw materials and production of semi-finished products. Part 2. Production of semi-finished products]. St. Petersburg, 2003, 633 p. (in Russ.).

Dul'kin D.A., Spiridonov V.A., Komarov V.I. Sovremennoye sostoyaniye i perspektivy ispol'zovaniya vtorichnogo vo-lokna iz makulatury v mirovoy i otechestvennoy industrii bumagi. [Current status and prospects of using recycled fiber from waste paper in the global and domestic paper industries]. Arkhangelsk, 2007, 1118 p. (in Russ.).

Marcks R., Schildhauer G. Pulp and Paper International, 1986, vol. 28, no. 11, pp. 48–49.

Tan L. Pulp and Paper International, 1986, vol. 28, no. 6, pp. 58–59.

Chen Zhong-sheng, Zhang Cheng-fang. Huadong ligong daxue xuebao. J.E. China Univ. Sci. and Technol., 2002, no. 5, pp. 487–491.

Copyright (c) 2019 Khimiia rastitel'nogo syr'ia (Chemistry of plant raw material)

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.