THE NEW METHOD OF OBTAINING MICROFIBRILLATED CELLULOSE FROM SPRUCE WOOD

UDC 547.458.8

Abstract

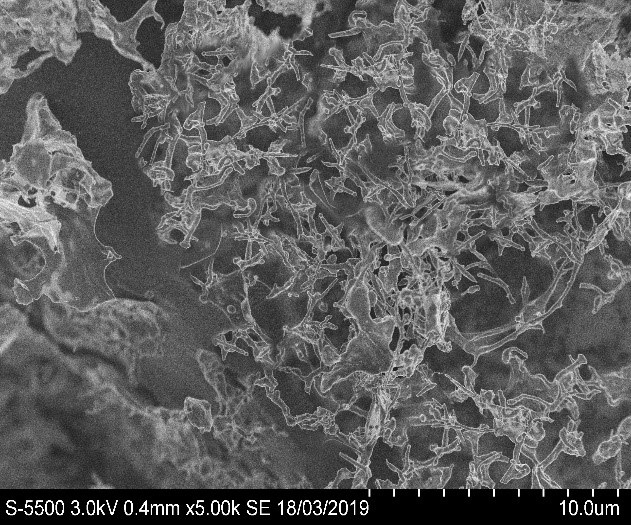

The new method of producing of microfibrillated cellulose (MFC) from spruce wood was described. This method includes the stages of cellulose obtaining by peroxide delignification of wood in the medium “acetic acid-water-H2SO4 catalyst” and cellulose acid hydrolysis, ultrasonic treatment, and freeze drying. The structure of cellulosic products was studied by FTIR, XRD, SEM, AFM, dynamic light scattering methods. The particle size of final cellulosic products is characteristic of microfibrillated cellulose according to the TAPPI Standard WI 3021 classification. The particles of the MFC are characterized by a rather high surface charge, and its aqueous suspension showed a high colloidal stability for a long time. According to the AFM data the surface of the microfibrillated cellulose film is formed by homogeneous spherical particles with a diameter about 80 nm and does not contain external inclusions.

The new method of obtaining MFC from spruce wood is less energy-consuming and more environmentally friendly compared to traditional technologies due to single-stage production of high quality cellulose without the use of sulfur- and chlorine containing delignifying agents, increased pressure and high water consumption.

Downloads

Metrics

References

Moon R.J., Martini A., Nairn J., Simonsen J., Youngblood J. Chem Soc Rev., 2011, vol. 40, pр. 3941–3994. DOI: 10.1039/C0CS00108B.

Osong S.H., Norgren S., Engstrand P. Cellulose, 2016, vol. 23, pр. 93–123. DOI: 10.1007/s10570-015-0798-5.

Charreau H., Foresti M.L., Va´zquez A. Recent Pat Nanotechnol., 2013, vol. 7(1), pp. 56–80. DOI: 10.2174/1872210511307010056.

Zhou S., Liu P., Wang M., Zhao H., Yang J., Xu F. ACS Sustainable Chem. Eng., 2016, vol. 4 (12), pp. 6409–6416. DOI: 10.1021/acssuschemeng.6b01075.

Du H., Liu W., Zhang M., Si Ch., Zhang X., Li B. Carbohydrate Polymers, 2019, vol. 209, pp. 130–144. DOI: 10.1016/j.carbpol.2019.01.020.

Lepetit A., Drolet R., Tolnai B., Montplaisir D., Lucas R., Zerrouki R. Cellulose, 2017, vol. 24, no. 10, pp. 4303–4312. DOI: 10.1007/s10570-017-1429-0.

Lavoine N., Desloges I., Dufresne A., Bras J. Carbohydrate Polymers, 2012, vol. 90, pр. 735–764. DOI: 10.1016/j.carbpol.2012.05.026.

Spence K.L., Venditti R.A., Rojas O.J., Habibi Y., Pawlak J.J. Cellulose, 2011, vol. 18, pp. 1097–1111. DOI: 10.1007/s10570-011-9533-z.

Siqueira G., Tapin-Lingua S., Bras J., Da Silva Perez D., Dufresne A. Cellulose, 2010, vol. 18(1), pp. 57–65. DOI: 10.1021/bm700769p.

Saito T., Nishiyama Y., Putaux J.-L., Vignon M., Isoga A. Biomacromolecules, 2006, vol. 7 (6), pp. 1687–1691. DOI: 10.1021/bm060154s.

Qing Y., Sabo R., Zhu J.Y., Agarwal U., Cai Z., Wu Y. Carbohydrate Polymers, 2013, vol. 97(1), pp. 226–234. DOI: 10.1016/j.carbpol.2013.04.086.

Kuznetsov B.N., Kuznetsova S.A., Danilov V.G., Yatsenkova O.V., Petrov A.V. Reaction Kinetics Mechanisms and Catysis, 2011, vol. 104, pp. 337–343. DOI: 10.1007/s11144-011-0354-8.

Kuznetsov B.N., Kuznetsova S.A., Levdansky V.A., Levdansky A.V., Vasil’eva N.Yu., Chesnokov N.V., Ivanchen-ko N.M., Djakovitch L., Pinel C. Wood Science and Technology, 2015, vol. 49, no. 4, pp. 825–843. DOI: 10.1007/500226-015-0723-y.

Wadenbäck J., Clapham D.H, Gellerstedt G., Arnold S. Holzforschung, 2004, vol. 58(2), pp. 107–115. DOI: 10.1515/HF.2004.015.

Sjöström E., Alen R. Analytical methods of wood chemistry. Pulping and papermaking. Berlin: Springer-Verlag, 1999, 318 p.

Nascimento S.A., Rezende C.A. Carbohydrate Polymers, 2018, vol. 180, pp. 38–45. DOI: 10.1016/j.carbpol.2017.09.099.

Carbohydrate composition of extractive-free wood and wood pulp by gas-liquid chromatography (Reaffirmation of T 249 сm-09). Tappi, 2009.

Ruiz-Matute A.I., Hernandez-Hernandez O., Rodriguez-Sanchez S., Sanz M.L., Martinez Castro I. J. Chromatogr. B., 2011, vol. 879, pp. 1226–1240. DOI: 10.1016/j.jchromb.2010.11.013.

Park S., Baker J.O., Himmel M.E., Parilla P.A., Jonson D.K. Biotechnology and Biofuels, 2010, vol. 3, p. 10. DOI: 10.1186/1754-6834-3-10.

Elazzouzi-Hafraou S., Nishiyama Y., Putaux J.-L., Heux L., Dubreuil F., Rochas C. Biomacromolecules, 2008, vol. 9(1), pp. 57–65. DOI: 10.1021/bm700769p.

Hallac B.B., Ragauskas A.J. Biofuels Bioprod Bioref., 2011, vol. 5, pp. 215–225. DOI: 10.1002/bbb.269.

GOST 2789-73 (Rekomendatsiya ISO R 286). Sherokhovatost' poverkhnosti. Parametry i kharakteristiki. [GOST 2789-73 (Recommendation ISO R 286). Surface roughness. Parameters and characteristics]. Moscow, 2006, 7 p. (in Russ.).

Xu F., Yu J., Tesso T., Dowell F., Wang D. Applied Energy, 2013, vol. 104, pp. 801–809. DOI: 10.1016/j.apenergy.2012.12.019.

Ghaffar S.H., Fan M. Biomass and Bioenergy, 2013, vol. 57, pp. 264–279. DOI: 10.1016/j.biombioe.2013.07.015.

Carrillo I., Mendonça R.T., Ago M., Rojas O.J. Cellulose, 2018, vol. 25, pp. 1011–1029. DOI: 10.1007/s10570-018-1653-2.

Carrillo F., Colom X., Sunol J.J., Saurina J. European Polymer Journal, 2004, vol. 40, pp. 2229–2234. DOI: 10.1016/j.eurpolymj.2004.05.003.

Ishankhodzhayeva M.M., Golen'kov S.V., Derkacheva O.Yu. Khimiya rastitel'nogo syr'ya, 2014, no. 3, pp. 105–110. (in Russ.).

Åkerholm M., Hinterstoisser B., Salmén L. Carbohydr. Res., 2004, vol. 339, pp. 569–578. DOI: 10.1016/j.carres.2003.11.012.

Ioyelovich M.Ya. Khimiya rastitel'nogo syr'ya, 2016, no. 3, pp. 5–10. DOI: 10.14258/jcprm.2016031210 (in Russ.).

Ago M., Endo T., Hirotsu T. Cellulose, 2004, vol. 11, pp. 163–167. DOI: 10.1023/B:CELL.0000025423.32330.fa

Phanthong P., Karnjanakom S., Reubroycharoen P., Hao X., Abudula A., Guan G. Cellulose, 2017, vol. 24, pp. 2083–2093. DOI: 10.1007/s10570-017-1238-5.

Aulin C., Ahola S., Josefsson P., Nishino T., Hirose Y., Osterberg M. et al. Langmuir, 2009, vol. 25(13), pp. 7675–7685. DOI: 10.1021/la900323n.

Li X., Li J., Gong J., Kuang Y., Mo L., Song T. Carbohydrate Polymers, 2018, vol. 183, pp. 303–310. DOI: 10.1016/j.carbpol.2017.12.085.

Xiao Sh., Gao R., Lu Y., Li J., Sun Q. Carbohydrate Polymers, 2015, vol. 119, pр. 202–209. DOI: 10.1016/j.carbpol.2014.11.041.

Hishikawa Y., Togawa E., Kondo T. ACS Omega, 2017, vol. 2, pp. 1469−1476. DOI: 10.1021/acsomega.6b00364

Nuruddin M., Hosur M., Uddin M.J., Baah D., Jeelani S. J. Appl. Polym. Sci., 2016, vol. 133(9), p. 42990. DOI: 10.1002/app.42990.

Shankar Sh., Rhim J.-W. Carbohydrate Polymers, 2016, vol. 135, pp. 18–26. DOI: 10.1016/j.carbpol.2015.08.082.

Gong J., Li J., Xu J., Xiang Z., Mo L. RSC Adv., 2017, vol. 7, pp. 33486–33493. DOI: 10.1039/C7RA06222B.

Pang J.H., Wu M., Zhang Q.H., Tan X., Xu F., Zhang X.M., Sun R.C. Carbohydrate Polymers, 2015, vol. 121, pр. 71–78. DOI: 10.1016/j.carbpol.2014.11.067.

Niu F., Li M., Huang Q., Zhang X., Pan W., Yang J., Li J. Carbohydrate Polymers, 2017, vol. 165, pp. 197–204. DOI: 10.1016/j.carbpol.2017.02.048.

Copyright (c) 2020 Khimiia rastitel'nogo syr'ia (Chemistry of plant raw material)

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.