FEATURES OF LARIX SIBIRICA LEDEB WOOD PROCESSING INTO HIGH YIELD FIBROUS SEMI-FINISHED PRODUCTS

UDC 676.15:606:66.022.3:577.15

Abstract

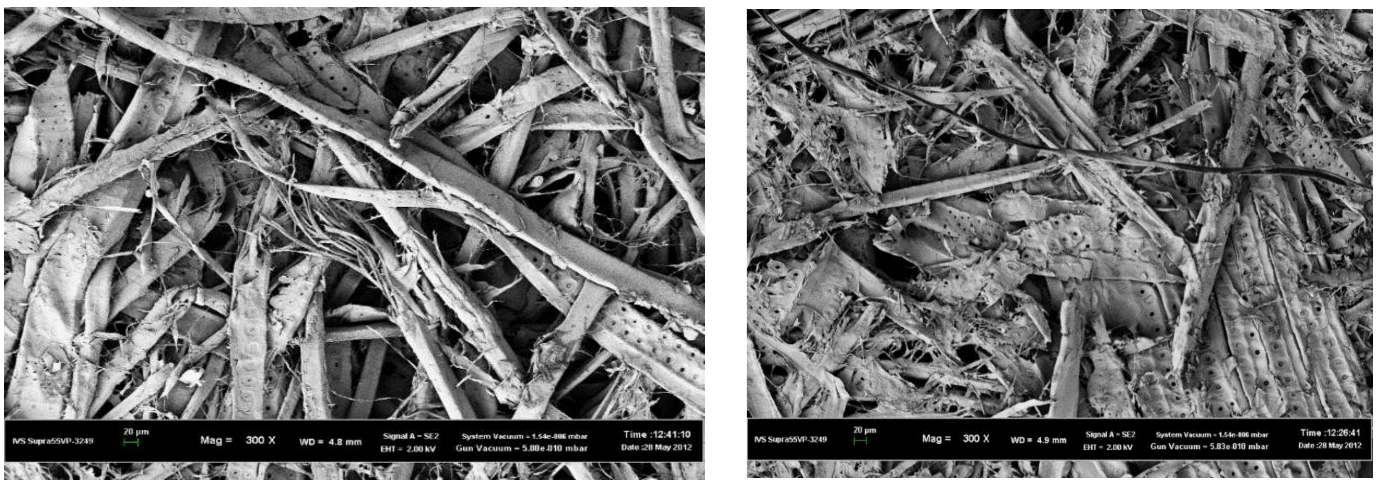

About 40 % of the forest area in the Russian Federation is occupied by larch trees growing in the southern regions of Eastern Siberia and the Far East, where existing and reconstructed woodworking enterprises are located. In this regard, the use of larch wood in the production of fibrous semi-finished products is an urgent task for the Russian forest complex. As is known, larch wood contains a large number of extractive substances that have a significant impact on the process of its deep chemical processing. Therefore, it can be assumed that the production of wood (mechanical) pulp from larch wood, in particular chemical-thermomechanical pulp (CTMP), will be very effective, but with its own specific features. In this paper, it is proposed to modify the technology by using enzymes – protein catalysts of various reactions. The purpose of this study is to determine the potential of using larch wood enzymatic treatment in CTMP-technology, to evaluate the effect of enzymes on the physical and mechanical parameters of the fiber and the specific energy consumption during refining. Industrial samples of Larix sibirica Ledeb (Pinaceae) wood chips were used to obtain CTMP. Five commercially available enzymatic agents were used to treat wood chips. CTMP was obtained using laboratory equipment that simulates the industrial stages of production. Enzymatic treatment of larch wood has shown an improvement in the technological parameters of CTMP production, namely, a decrease in the specific energy consumption for refining and an increase in the quality of finished products.

Downloads

Metrics

References

The Russian Federation Forest Sector Outlook. Study To 2030. Rome: FAO UN, 2012, 87 p.

Nikitin N.I. Khimiya drevesiny i tsellyulozy [Wood and Pulp Chemistry]. Moscow-Leningrad, 1962, 711 p. (in Russ.).

Levin E.D., Denisov O.B., Pen R.Z. Kompleksnaya pererabotka listvennitsy [Complex Processing of Larch Wood]. Moscow, 1978, 224 p. (in Russ.).

Akim E.L. Khimicheskie volokna, 2016, no. 3, pp. 14–18. (in Russ.).

Babkin V.A. Rossiyskiy khimicheskiy zhurnal, 2004, vol. 48, no. 3, pp. 62–69. (in Russ.).

Нerbert P., Akim E.L. Tsellyuloza. Bumaga. Karton, 2011, no. 6, pp. 3-8. (in Russ.).

Akim E.L. Issledovanie protsessa sinteza voloknoobrazuyushchikh atsetatov tsellyulozy. Diss. dokt. tekhn. nauk [Study of the Synthesis of Fiber-Forming Acetates of Cellulose: diss. Dr. tech. sci.]. Leningrad, 1971. (in Russ.).

Zakharov A.G., Novoselov N.P., Sashina E.S., Parfenyuk E.V., Davydova O.I., Terekhova I.V., Kulikov O.V., Agafonov A.V., Prusov A.N., Kulichikhin V.G., Golova L.K., Akim E.L., Lipatova I.M., Moryganov A.P., Koksharov S.A., Aleeva S.V. Nauchnye osnovy khimicheskoy tekhnologii uglevodov [Scientific Basis of Carbohydrates Chemical Technology]. Moscow, 2008, 528 p. (in Russ.).

Akim E.L., Smolin A.S. Khimicheskie volokna, 2018, no. 4, pp. 81–88. (in Russ.).

Akim E.L., Rogovina S.Z., Berlin A.A. Doklady Rossiyskoy akademii nauk. Khimiya, nauki o materialakh, 2020, vol. 491, no. 1, pp. 73–76. (in Russ.).

Akim E.L., Pekaretz A.A., Rogovina S.Z., Berlin A.A. Vse materialy. Entsiklopedicheskiy spravochnik [All Material. Encyclopedic Reference Book], 2020, no. 9, pp. 3–8. (in Russ.).

Pekaretz A.A., Erokhina O.A., Novozhilov V.V., Mandre Yu.G., Akim E.L. Izvestiya Vysshikh Uchebnykh Zavedeniy. Lesnoy zhurnal, 2020, no. 1, pp. 200–209. DOI: 10.17238/issn0536-1036.2020.1. (in Russ.).

Akim E.L., Mandre Yu.G., Pekaretz A.A. Khimicheskie volokna, 2019, no. 3, pp. 14–18. DOI: 10.1007/s10692-019-10067-8. (in Russ.).

Patent 2596683 (RU). 2016. (in Russ.).

Pekaretz A., Mandre Y., Vinogradov N., Akim E. Proceedings of the 27th European Biomass Conference and Exhibi-tion, Lisbon, 2019, pp. 1887–1889.

Vinogradov N., Pekaretz A., Fedorova A., Mandre Y., Akim E. Proceedings of the 28th European Biomass Confer-ence and Exhibition, Marseille, 2020.

Kuznetsov A.G. Razrabotka putey krupnotonnazhnogo ispol'zovaniya arabinogalaktana – produkta glubokoy pere-rabotki drevesiny listvennitsy: avtoref. dis. … kand. tekhn. nauk [Development of Ways of Large-Capacity Use of Arab-inogalactan – the Product of Deep Processing of Larch Wood. Cand. tech. sci. diss. abstr.]. St.-Petersburg, 2015, 16 p. (in Russ.).

Vinogradov N.V. Kompressionnye svoystva drevesiny listvennitsy kak osnova otzhimnoy tekhnologii izvlecheniya arab-inogalaktana: avtoref. dis. … kand. tekhn. nauk [Compression Properties of Larch Wood as the Basis of Pressing Technology for Extracting Arabinogalactan. Cand. tech. sci. diss. abstr.]. St.-Petersburg, 2019. 16 p. (in Russ.).

Novozhilov E.V. Primenenie fermentnykh tekhnologiy v tsellyulozno-bumazhnoy promyshlennosti [Application of En-zyme Technologies in Pulp and Paper Industry]. Arkhangelsk, 2013, 383 p. (in Russ.).

Mohlin U.B., Pettersson B. Biotechnology in the Pulp and Paper industry, 2002, vol. 21, pp. 291–300.

Mustranta A., Buchert J., Spetz P., Holmbom B. Nordic Pulp Paper Res. J., 2001, vol. 16, no. 2, pp. 125–129.

Gorski D. ATMP Process. Improved Energy Efficiency in TMP Refining Utilizing Selective Wood Disintegration and Targeted Application of Chemicals. Thesis for the degree of Doctor of technology. Sundsvall, 2011, 119 p.

Aehle W. Enzymes in Industry, Production and Application. Wiley-VCH, 2004, 484 p.

Pursula T. Bringing Life to Paper, Biotechnology in the Forest Industry. KCL Research Project 1136-201, 2005.

Akim E.L., Molotkov L.K., Saprykina N.N., Kovalenko M.V., Mandre Yu.G., Makhotina L.G., Sergeev A.D., Vinogradov N.V. Tsellyuloza. Bumaga. Karton, 2011, no. 7, pp. 26–31. (in Russ.).

Kovalenko M.V., Kazymov D.S. Materialy VIII mezhdunarodnoy nauchno-prakticheskoy konferentsii "Nauchnoe prostranstvo Evropy – 2012" [Proceedings of the 8th international scientific and practical conference "Scientific space of Europe – 2012"], 2012, no. 35, pp. 54–58. (in Russ.).

Viikari L. Encyclopedia of Microbiology, Elsevier, 2009, pp. 85–99.

Pere J., Ellmen J., Honkasalo J., Taipalus P. Biotechnology in the Pulp and Paper Industry, 2002, vol. 21, pp. 281–290.

Kallioinen A. Biotechnical Methods for Improvement of Energy Economy in Mechanical Pulping. VTT, 2002, 98 p.

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.