HETEROGENEOUS CATALYTIC FRACTIONATION OF BIRCH-WOOD BIOMASS INTO MICROCRYSTALLINE CELLULOSE, XYLOSE AND ENTEROSORBENTS

UDC 676.1.022.6.001.5

Abstract

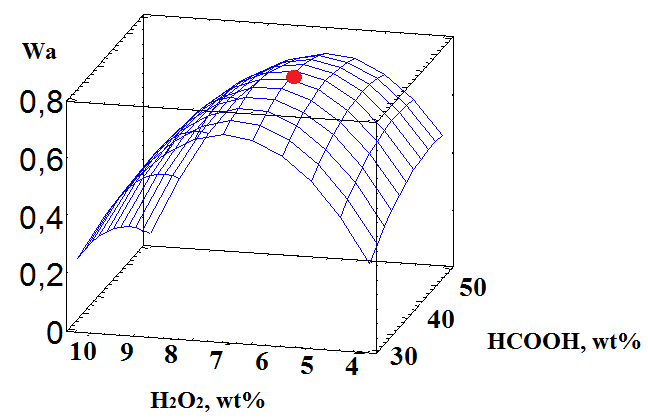

For the first time, it was proposed to fractionate the main components of birch wood into microcrystalline cellulose, xylose and enterosorbents by integrating heterogeneous catalytic processes of acid hydrolysis and peroxide delignification of wood biomass. The hydrolysis of wood hemicelluloses into xylose is carried out at a temperature of 150 °C in the presence of a solid acid catalyst Amberlyst® 15. Then the lignocellulosic product undergoes peroxide delignification in a "formic acid – water" medium in the presence of a solid TiO2 catalyst to obtain microcrystalline cellulose (MCC) and soluble lignin. Under the determined optimal conditions (100 °С, Н2О2 – 7.2 wt.%, НСООН – 37.8 wt.%, LWR 15, time 4 h), the yield of MCC reaches 64.5 wt.% and of organosolvent lignin 11.5 wt% from the weight of prehydrolyzed wood. By the treatment of organosolvent lignin with a solution of 0.4% NaHCO3 or hot water the enterosorbents were obtained, whose sorption capacity for methylene blue (97.7 mg/g) and gelatin (236.7 mg/g) is significantly higher than that of the commercial enterosorbent Polyphepan (44 mg/g and 115 mg/g, respectively). The products of catalytic fractionation of birch wood are characterized by physicochemical (FTIR, XRD, SEM, GC) and chemical methods.

Downloads

Metrics

References

Cherubini F. Energy Conversion and Management, 2010, vol. 51, pp. 1412–1421. DOI: 10.1016/j.enconman.2010.01.015.

Bajpai P. Biorefinery in the pulp and paper industry. Elsevier, 2013, 114 p. DOI: 10.1016/C2012-0-06724-5.

Environmentally Friendly Technologies for the Pulp and Paper Industry. Ed. Raymond A. Young and Masood Akhtar. John Wiley&Sons, Inc. 1998. 577 p.

Ferrer A., Vega A., Rodriguez A., Ligero P., Jimenez L. Bioresource Technology, 2011, vol. 102, pp. 9755–9762.

Garyntseva N.V., Sudakova I.G., Chudina A.I., Malyar Yu.N., Kuznetsov B.N. J. Sib. Fed. Univ. Chem., 2019, vol. 12, no. 4, pp. 522–535. DOI: 10.17516/1998-2836-0148. (in Russ.).

Kuznetsov B.N., Malyar Yu.N., Kuznetsova S.A., Grishechko L.I., Kazachenko A.S., Levdansky A.V., Pestunov A.V., Boyandin A.N., Celzard A. J. Sib. Fed. Univ. Chem., 2016, vol. 9, no. 4, pp. 454–482. DOI: 10.17516/1998-2836-2016-9-4-454-482. (in Russ.).

Liu X., Feng Sh., Fang Q., Jiang Zh., Hu Ch. Molecular Catalysis, 2020, vol. 495. 111164. DOI: 10.1016/j.mcat.2020.111164.

Kazachenko A.S., Baryshnikov S.V., Chudina A.I., Malyar YU.N., Sychev V.V., Taran O.P., D'yakovich L., Kuznetsov B.N. Khimiya rastitel'nogo syr'ya, 2019, no. 2, pp. 15–26. DOI: 10.14258/jcprm.2019025108. (in Russ.).

Dussan K., Girisuta B., Haverty D., Leahya J.J., Hayes M.H.B. Carbohydrate Polymers, 2014, vol. 111, pp. 374–384. DOI: 10.1016/j.carbpol.2014.04.039.

Ma R., Xu Y., Zhang X. ChemSusChem, 2015, vol. 8, pp. 24–51. DOI: 10.1002/cssc.201402503.

Ramadoss G., Muthukumar K. Chem. Eng. J., 2015, vol. 260, pp. 178–187. DOI: 10.1016/j.cej.2014.08.006.

Kuznetsov B.N., Sudakova I.G., Garyntseva N.V., Levdansky V.A., Ivanchenko N.M., Pestunov A.V., Djakovitch L., Pinel C. Wood Science and Technology, 2018, vol. 52, pp. 1377–1394. DOI: 10.1007/s00226-018-1029-7.

Borrega M., Nieminen K., Sixta H. BioResources, 2011, vol. 6, no. 2, pp. 1890–1903.

Sjöström E., Alern R. Analytical Methods of Wood Chemistry. Pulping and Papermaking, Springer-Verlag, 1999. 318 p.

Vilcocq L., Castilho P., Carvalheiro F., Duarte L. ChemSusChem., 2014, vol. 7, Pp. 1010–1019. DOI: 10.1002/cssc.201300720.

Hu L., Lin L., Wu Z., Zhou S., Liu S. Applied Catalysis B: Environmental, 2015, vol. 174–175, pp. 225–243.

Sudakova I.G., Garyntseva N.V., Chudina A.I., Kuznetsov B.N. Khimiya rastitel'nogo syr'ya, 2018, no. 4, pp. 63–71. DOI: 10.14258/jcprm.2018044079. (in Russ.).

Reshetnikov V.I. Pharmaceutical Chemistry Journal, 2003, vol. 37, no. 5, pp. 246–251.

Ruiz-Matute A.I., Hernandez-Hernandez O., Rodriguez-Sanchez S., Sanz M.L., Martinez-Castro I. J. Chromatogr. B., 2011, vol. 879, pp. 1226–1240. DOI: 10.1016/j.jchromb.2010.11.013.

Testova L., Vilonen K.M., Pynnönen H., Tenkanen M. Lenzinger Berichte, 2009, vol. 87, pp. 58–65.

Degirmenci V, Uner D, Cinlar B et al. Catalysis Letters, 2011, vol. 141, pp. 33–42. DOI: 10.1007/s10562-010-0466-1.

Wu C., Bing L., Li S., Yu D., Wang D. BioResources, 2016, vol. 11, no. 1, pp. 87–94. DOI: 10.15376/biores.11.1.87-94.

Nakajima K., Okamura M., Kondo, et al. Chem. Mater., 2009, vol. 21, pp. 186–193. DOI: 10.1021/cm801441c.

Kuznetsov B.N., Yatsenkova O.V., Chudina A.I., Skripnikov A.M., Kozlova S.A., Garyntseva N.V., Chesnokov N.V. J. Sib. Fed. Univ. Chem. 2014, vol. 7, no. 1, pp. 122–133. (in Russ.).

Yatsenkova O.V., Chudina A.I., Skripnikov A.M., Chesnokov N.V., Kuznetsov B.N. J. Sib. Fed. Univ. Chem., 2015, vol. 8, no. 2, pp. 211–221. DOI: 10.17516/1998-2836-2015-8-2-211-221. (in Russ.).

Kuznetsov B.N., Sudakova I.G., Garyntseva N.V., Tarabanko V.E., Yatsenkova O.V., Djakovitch L., Rataboul F. Catal-ysis Today, 2021, vol. 375, pp. 132–144. DOI: 10.1016/j.cattod.2020.05.044.

NIST/SEMATECH e-Handbook of Statistical Methods. URL: http://www.itl.nist.gov/div898/handbook/. DOI: 10.18434/M32189.

Pen R.Z. Planirovaniye eksperimenta v Statgraphics. [Planning an experiment in Statgraphics]. Krasnoyarsk, 2012, 270 p. (in Russ.).

Adel A.M., Abd El-Wahab Z.H., Ibrahim A.A., Al-Shemy M.T. Carbohydrate Polymers, 2001, vol. 83, no. 2, pp. 676–687. DOI: 10.1016/j.carbpol.2010.08.039.

Fan M., Dai D., Huang B. International Conference on Innovative Technologies (IN-TECH 2012), Rejeka, Croatia, 2012, pp. 45–68.

Nishiyama Y, Langan P, Chanzy H. J. Am. Chem. Soc., 2002, vol. 124, pp. 9074–9082. DOI: 10.1021/ja0257319.

Park S., Baker J.O., Himmel M.E., Parilla P.A., Jonson D.K. Biotechnol Biofuels., 2010, vol. 3. 10. DOI: 10.1186/1754-6834-3-10.

Garyntseva N.V., Sudakova I.G., Kuznetsov B.N. J. Sib. Fed. Univ. Chem., 2011, vol. 4, no. 2, pp. 121–126. (in Russ.).

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.