INTERRELATION OF INDIVIDUAL PAPER-FORMING PROPERTIES AND THE DYNAMIC VISCOSITY COEFFICIENT DURING THE GRINDING OF THE FIBROUS MASS

UDC 676.024

Abstract

The refining process is associated with the movement of large masses of fibrous suspensions in the working bodies of refining machines, which affects both the refining process itself and energy consumption when moving the fibrous suspension. In this regard, the efficiency of refining equipment can be ensured on the basis of knowledge of the hydrodynamic processes that occur during the interaction of the working bodies of refining equipment with a fibrous suspension.

During the flow of fibrous suspensions, the basic rheological feature is their viscosity, which makes it possible to judge the internal forces acting in the flow. This is especially important for the bladeless refining method using the “jet-barrier” installation.

In order to most fully judge the direction of the refining process (in the direction of the transverse shortening of the fibers or in the direction of their longitudinal fibrillation), it is necessary to control the paper-forming properties of the fibrous mass and the physical and mechanical properties of the castings.

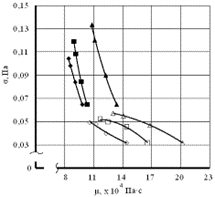

The publication presents an analysis of the influence of the paper-forming properties of the fibrous mass on the quality of its refining, it is advisable to find the dependence of these indicators on the rheological features of the fibrous suspension flow in the refining zone, that is, to determine the relationship of the paper-forming properties of the fibrous mass with the dynamic viscosity coefficient during the flow of the fibrous suspension in the refining zone.

Downloads

Metrics

References

Vasyutin V.G. Intensifikatsiya protsessa kombinirovannogo razmola tsellyuloznykh suspenziy: dis. ... kand. tekhn. nauk. [Intensification of the process of combined grinding of cellulose suspensions: dis. ... cand. tech. sciences.]. Kras-noyarsk, 1987, 166 p. (in Russ.).

Shirenin V.M. Mekhanizm gidrodinamicheskoy obrabotki voloknistykh materialov v beznozhevoy razmol'noy ustanovke: avtoref. dis. … kand. tekhn. nauk. [The mechanism of hydrodynamic processing of fibrous materials in a knifeless grinding plant: Ph.D. dis. … cand. tech. sciences]. Krasnoyarsk, 2003, 20 p. (in Russ.).

Terent'yev O.A. Gidrodinamika voloknistykh suspenziy v tsellyulozno-bumazhnom proizvodstve. [Hydrodynamics of fibrous suspensions in pulp and paper production]. Moscow, 1980, 248 p. (in Russ.).

Alashkevich Yu.D. Gidrodinamicheskiye yavleniya pri beznozhevoy obrabotke voloknistykh materialov. [Hydrodynam-ic phenomena during knifeless processing of fibrous materials]. Krasnoyarsk, 2004, 80 p. (in Russ.).

Kutovaya L.V. Kompleksnyy parametr protsessa obrabotki voloknistykh suspenziy beznozhevym sposobom v ustanovke tipa «struya-pregrada»: dis. … kand. tekh. nauk. [A complex parameter of the process of processing fibrous suspen-sions using a knifeless method in a “jet-barrier” type installation: dis. … cand. tech. sciences.]. Krasnoyarsk, 1998, 178 p. (in Russ.).

Terent'yev O.A., Kurov V.S. Reologiya i gidrodinamika bumazhnoy massy. [Rheology and Fluid Dynamics of Paper Pulp]. Leningrad, 1986, 81 p. (in Russ.).

Yerofeyeva A.A., Kovalev V.I., Alashkevich Yu.D. Khimiya Rastitel'nogo Syr'ya, 2009, no. 3, pp. 165–168. (in Russ.).

Smirnova E.A. Razrabotka modeli kompleksnoy reologicheskoy kharakteristiki bumazhnoy massy s tsel'yu praktich-eskogo ispol'zovaniya pri optimizatsii rezhimov raboty gidravlicheskogo oborudovaniya TSBP: dis. … kand. tekhn. nauk. [Development of a model for the complex rheological characteristics of paper pulp for the purpose of practical use in optimizing the operating modes of the hydraulic equipment of the pulp and paper industry: dis. … cand. tech. Sciences]. Leningrad,1983, 228 p. (in Russ.).

Patent 2441217 (RU). 2012. (in Russ.).

Yerofeyeva A.A., Kovalev V.I., Alashkevich Yu.D. Lesnoy zhurnal, 2011, no. 4, pp. 115–119. (in Russ.).

Apsit S.O., Kilipenko A.V. Bumagoobrazuyushchiye svoystva voloknistykh polufabrikatov. [Paper-forming properties of fibrous semi-finished products]. Moscow, 1972, 88 p. (in Russ.).

Uatte U. Ekspress-informatsiya, 1968, no. 23. (in Russ.).

Kovalev V.I., Yerofeyeva A.A., Alashkevich Yu.D. Novyye dostizheniya v khimii i khimicheskoy tekhnologii ras-titel'nogo syr'ya. [New advances in chemistry and chemical technology of plant raw materials]. Barnaul, 2009, pp. 219–221. (in Russ.).

Kovalev V.I. Razmol voloknistykh polufabrikatov pri razlichnom kharaktere postroyeniya risunka nozhevoy garnitury: avtoref. dis. … kand. tekhn. nauk. [Grinding fibrous semi-finished products with a different nature of the construction of the pattern of the knife set: author. dis. … cand. tech. Sciences]. Krasnoyarsk, 2007, 22 p. (in Russ.).

Geguzin Ya.Ye. Kaplya. [A drop]. Moscow, 1977, 175 p. (in Russ.).

Reshetova N.S. Razmol tsellyulozy beznozhevym sposobom v magnitnom pole: dis. … kand. tekhn. nauk. [Grinding of cellulose using a knifeless method in a magnetic field: dis. … cand. tech. sciences]. Krasnoyarsk, 2002, 138 p. (in Russ.).

Stepanova I.V., Tarasov A.V. Vyazkost' zhidkikh sred. [Viscosity of liquid media]. Saint Petersburg, 2006, 37 p. (in Russ.).

Solov'yev A.N., Kaplun A.B. Vibratsionnyy metod izmereniya vyazkosti zhidkosti. [Vibration method for measuring the viscosity of a liquid]. Novosibirsk, 1970, 140 p. (in Russ.).

Byvshev A.V. Submikroskopicheskoye stroyeniye drevesiny i yego rol' v protsessakh delignifikatsi: Tezisy dokladov 4-go nauch. seminara. [Submicroscopic structure of wood and its role in delignification processes: Abstracts of the 4th scientific seminar]. Riga, 1990, pp. 93–98. (in Russ.).

Pokrovskiy V.N. Uspekhi fizicheskikh nauk, 1992, vol. 162, no. 5, pp. 87–120. (in Russ.).

Copyright (c) 2022 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.