EFFECT OF MODIFIERS ON THE STRUCTURAL FEATURES OF CARBONACEOUS COMPOSITE DURING CARBONIZATION OF PINE WOOD

Abstract

Porous carbonaceous materials from pine sawdust modified with FeCl3, ZnCl2 and H3PO4 have been synthesized. A comparative analysis of their structure and properties at different temperatures of carbonization and subsequent a treatment water has been carried out using thermal adsorption of nitrogen for determine of specific surface, electron microscopy and X-ray analysis.

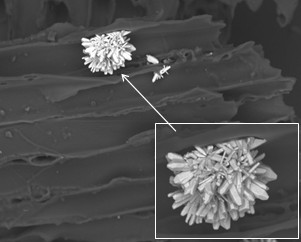

It was revealed that homogeneous amorphous-crystalline structure of product is formed in heating of samples with H3PO4; carbonization of samples with FeCl3 leads to formation of crystalline phases including magnetite, but carbonization of samples with addition of ZnCl2 creates basic two phases – amorphous-crystalline and hexagonal crystallites of zinc oxide that impart special properties of the products.

It has been shown that the addition of ferric chloride allows to obtain magnetite/carbon composite having a specific surface area of 470 m2 g-1; the addition of zinc chloride in biomass leads to the formation of a zinc oxide/carbon composite having a specific surface of 1900 m2 g-1; and the addition of phosphoric acid results polyphosphate-carbon structure with a specific surface area up to 1300 m2 g-1. It has been revealed that the porosity of the product is associated mainly with the formation of the water-insoluble of crystal-like fragments for carbonization.Downloads

Metrics

References

Marsh H., Rodriguez-Reinoso F. Activated Carbon. Elsevier Ltd., 2006, 536 p.

Fenelonov V.B. Vvedenie v fizicheskuju himiju formirovanija supramolekuljarnoj struktury adsorbentov i katalizatorov. [Introduction to the physical chemistry of formation of supramolecular structure of adsorbents and catalysts]. Novosibirsk, 2002, 414 p. (in Russ.).

Munoz-Gonzalez Y., Arriagada-Acuna R., Soto-Garrido G., Garcıa-Lovera R. J. Chem Technol Biotechnol, 2009, vol. 84, pp. 39–47.

Derbyshire F., Jagtoyen M., Andrews R,. Rao A, Martın-Gullon I, Grulke E. In: Radovic, Editor, Chemistry and physics of carbon. Marcel Dekker, New York, 2001, vol. 27, pp. 1−66.

Tsyganova S., Patrushev V., Zhizhaev A. Wood Sci. Technol., 2015, pp. 869–878.

Tsyganova S.I., Zhizhaev A.M., Bondarenko G.N., Fetisova O.Iu. Khimiia rastitel'nogo syr'ia, 2015, no. 3, pp. 205–211. (in Russ.).

Kuznetsov B.N., Chesnokov N.V., Tsyganova S.I., Mikova N.M., Ivanov I.P., Ivanchenko N.M. Solid Fuel Chemistry, 2016, vol. 50, no. 1, pp. 23–30.

Tsyganova S.I., Korol’kova I.V., Chesnokov N.V., Kuznetsov B.N. Russian Journal of Bioorganic Chemistry, 2011, vol. 37, no. 7, pp. 809–813.

Hu J., Noked M., Gillette E., Han F., Gui Z., Wangc C., Bok Lee S. Journal of Materials Chemistry A, 2015, no. 3, pp. 21501–21510.

Fleker O., Borenstein A., Lavi R., Benisvy L., Ruthstein S., Aurbach D. Interface-Rich Materials and Assemblies, 2016, vol. 32, no. 19, pp. 4935–4944.

Setianingsih T., Kartini I., Arryanto Y. J. Pure App. Chem. Res., 2014, vol. 3, no. 3, pp. 114–122.

Swarnalatha S., Ganesh Kumar A., Sekaran G. J. Porous Mater., 2009, vol. 16, pp. 239–245.

Sui M., Gong P., Gu X. Front. Optoelectron, 2013, vol. 6, no. 4, pp. 386–412.

Kumar M.A., Jung S., Ji T. Sensors, 2011, vol. 11, pp. 5087−5111.

Kołodziejczak-Radzimska A., Jesionowski T. Materials, 2014, vol. 7, pp. 2833−2881.

Patent 2005137973 (JP). 2005.

Patent 101502789 (CN). 2009.

Afanas'ev S.V., Balakin V.M. Izvestiia Samarskogo nauchnogo tsentra RAN, 2014, vol. 16, no. 1, pp. 1682−1684. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.