THE ROLE OF FIBERS SURFACE IN DEVELOPMENT OF PAPERMAKING PROPERTIES OF TECHNICAL PULP IN THE REFINING PROCESS

Abstract

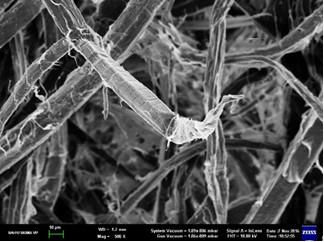

The aim of this work was to determine the relationship between the values of the fiber specific surface and papermaking properties of the pulp that are changing in the refining process. Quality data on the status and quantitative data on the value of the fibers specific surface for softwood and hardwood kraft pulp with different lignin content and different degree of refining were obtained. When preparing samples was used technology of cryofixation and freeze-drying the wet laboratory samples. The SEM-images of the cellulose fibers surface in the state such as for the sheet forming, obtained on scanning electron microscope ZEISS "SIGMA VP". The SEM-images shows just noticeable difference in development of the fibers surface in the beating process. This is manifested in an increase in the number of microfibrils on the fiber surface. Quantitative data were obtained on the automatic analyzer of the specific surface magnitude ASAP.

A visually apparent increase of the surface when beating technical cellulose confirmed quantitatively. The value of the specific surface area increased from 2 m2/g for cellulose after the dispergation into pulp of up to 4...6 m2/g after refining up to 60 °SR. Removal of lignin from cellulose promotes more intensive development of the surface during refining.

For different kinds of pulp, similar dependences of physical-mechanical properties (interfiber bonding forces, bulk density, modulus of elasticity) of laboratory samples and specific surface data, which change during refining, are established.

The main influence on the change in the structural-dimensional and elastic properties of paper during refining is exerted by an increase in the content of microfibrils on the outer surface of the fibers. The tightness of the correlation and the nature of the observed dependence depends on the wood species from which the cellulose is derived, on the lignin content of the samples, and on the drying method. For softwood pulp, the tightness of the relationship is higher than for hardwood pulp.

Downloads

Metrics

References

Ivanov S.N. Tekhnologiia bumagi. [Paper Technology]. Moscow, 2006, 696 p. (in Russ.).

Komarov V.I., Kazakov Ia.V., Derkacheva O.Iu., Sukhov D.A. Lesnoi zhurnal, 1998, no. 1, pp. 57–66. (in Russ.).

Herrington Т.M., Petzold J.С. Cellulose, 1995, no. 2, pp. 83–94.

Stone J.E., Scallan A.M., Abrahamson B. Svensk Papperstidning, 1968, vol. 71(19), pp. 687–694.

Komarov V.I. Deformatsiia i razrushenie voloknistykh tselliulozno-bumazhnykh materialov. [Deformation and destruc-tion of fibrous cellulose and paper materials]. Arkhangel'sk, 2002, 440 p. (in Russ.).

Dul'kin D.A., Spiridonov V.A., Komarov V.I. i dr. Svoistva tselliuloznykh volokon i ikh vliianie na fiziko-mekhanicheskie kharakteristiki bumagi i kartona. [Properties of cellulose fibers and their influence on the physical and mechanical characteristics of paper and paperboard]. Arkhangel'sk, 2011, 176 p. (in Russ.).

Ishisaki M., Naito T. 63rd Pulp and Paper Research Conference, Japan TAPPI, Tokyo, Japan, 1996, pp. 62–65.

Retulainen E., Luukko K., Fagerholm K., Pere J., Laine J., Paulapuro H. APPITA, 2002, vol. 55(6), pp. 457–460.

Kang T., Paulapuro H. Pulp &Paper Canada, 2006, vol. 107, no. 7/8, pp. 51–54.

Chukhchin D.G., Varakin E.A., Novozhilov E.V., Terent'ev K.Iu., Smirnov E.V., Belykh E.A. Fizikokhimiia ras-titel'nykh polimerov. Materialy V mezhdunarodnoi konferentsii. [Physicochemistry of plant polymers. Materials of the V international conference]. Arkhangel'sk, 2013, pp. 46–50. (in Russ.).

Kazakov Ia.V., Chukhchin D.G. Problemy mekhaniki tselliulozno-bumazhnykh materialov: materialy II Mezhdunarod-noi nauchno-tekhnologicheskoi konferentsii. [Problems of mechanics of pulp and paper materials: materials of the II In-ternational Scientific and Technological Conference]. Arkhangel'sk, 2013, pp. 56–63. (in Russ.).

Kazakov Ia.V., Chukhchin D.G., Lebedev I.V. Novye dostizheniia v khimii i khimicheskoi tekhnologii rastitel'nogo syr'ia: mate-rialy VI Vserossiiskoi konferentsii. [New achievements in chemistry and chemical technology of plant raw materials: materials of the VI All-Russian Conference]. Barnaul, 2014, pp. 27–29. (in Russ.).

Vorob'eva T.V., Kazakov Ia.V., Khromtsova R.G. Lesnoi zhurnal, 2013, no. 5, pp. 184–192. (in Russ.).

Dubovyi V.K., Gur'ev A.V., Kazakov Ia.V., Komarov V.I. Laboratornyi praktikum po tekhnologii bumagi i kartona: uchebnoe posobie. [Laboratory Practice on Paper and Cardboard Technology: A Tutorial]. St. Petersburg, 2006, 230 p. (in Russ.).

Beletskaia M.G., Bogdanovich N.I., Makarevich N.A. Tekhnologiia uglerodnykh adsorbentov. Fiziko-khimicheskii ana-liz aktivnykh uglei: uchebnoe posobie k laboratornomu praktikumu. [Technology of carbon adsorbents. Physicochemi-cal analysis of active coals: a textbook for laboratory practice]. Arkhangel'sk, 2015, 96 p. (in Russ.).

Viacheslavov A.S., Efremova M. Opredelenie ploshchadi poverkhnosti i poristosti materialov metodom sorbtsii gazov. [Determination of the surface area and porosity of materials by the method of gas sorption]. Moscow, 2011, 65 p. (in Russ.).

Manakhova T.N, Kazakov Ia.V. Vestnik Kazanskogo tekhnologicheskogo universiteta, 2013, no. 21, pp. 38–42. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.