SIMULATION MODEL OF THE PROCESS OF BIOGAS PRODUCTION FROM MULTICOMPONENT PLANT RAW MATERIALS. ANALYSIS AND PARAMETRIC OPTIMIZATION

Abstract

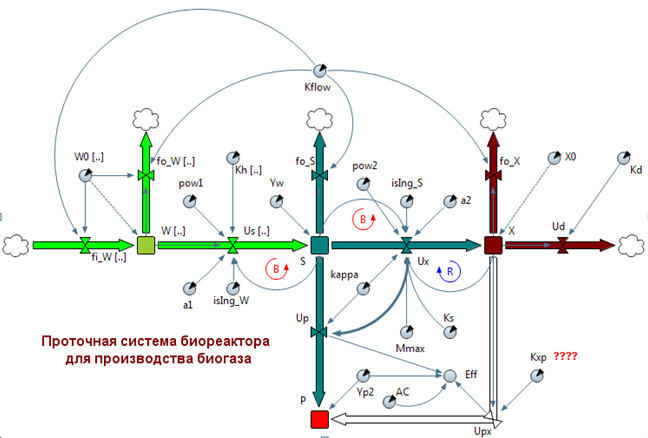

Article is devoted to the description and the analysis of the system-dynamic model of technological process of biogas production from multicomponent vegetable raw materials. A research objective – optimization of biogas production process from vegetable raw materials by methods of imitating modeling, finding of the optimal regimes of the simulated production cycle – the best ratio from the economic point of view between an exit of biomethane and rates of giving/replacement of the initial substratum depending on the composition of raw materials.

In article models with a discrete and continuous cycle of production are considered, the description of the similar realization executed in the environment of multiapproach modeling of AnyLogic for model of technological process of anaerobic digestion of non-uniform multicomponent vegetable biomass is provided.

The known stoichiometric model of production of biomethane is taken as a basis, her modification is made for a case of multicomponent raw materials (percentage division into conditional components – sugar, lignin and cellulose). Possibilities of modern software shells and environments of modeling in tasks of the complex analysis and optimization of the studied process are shown.

During the conducted researches a row of non-trivial results on a choice of optimum parameters of an operation mode of the model bioreactor is received. For a case of the discrete process of up-dating of contents as parameters of optimization the frequency and a level of up-dating, and for the continuous flowing system – channel speed were selected.

It is shown that the optimal values of the parameters from the point of view of the integrated output of the biomethane lie close to the cloud of critical acidification, which leads to the stoppage of the process. If the economic indicators are chosen as an optimization criterion, then we obtain optimal values of the parameters lying within the region of stable functioning of the model bioreactor.Downloads

Metrics

References

Dobrynina O.M, Kalinina E.V. Vestnik Permskogo gosudarstvennogo tekhnicheskogo universiteta. Okhrana okruz-haiushchei sredy, transport, bezopasnost' zhiznedeiatel'nosti, 2010, no. 2, pp. 33–40. (in Russ.).

Aiba S., Shoda M., Nagatani M. Biotechnology and Bioengineering, 1968, vol. 10, no. 6, pp. 845–864.

Grant D.J.W. Journal of General Microbiology, 1967, vol. 46, pp. 213–224.

Gujer, W., Zehnder A.J.B. Water Science and Technology, 1983, vol. 15, pp. 127–167.

Andrews J.F. Biotechnology and Bioengineering, 1968, vol. 10, pp. 707–723.

Gerber M., Span R. In: Proc., Int. Gas Union Research Conf., French Gas Association, Neuilly-sur-Seine, France, 2008.

Vavilin V.A., Vasil'ev V.B., Rytov S.V. Modelirovanie destruktsii organicheskogo veshchestva soobshchestvom mik-roorganizmov. [Modeling of the destruction of organic matter by a community of microorganisms]. Moscow, 1993, 204 p. (in Russ.).

Vavilin V.A., Vasiliev V.B., Ponomarev A.V., Rytow S.V. Bioresource Technology, 1994, vol. 48, pp. 1–8.

Biotekhnologiia i mikrobiologiia anaerobnoi pererabotki organicheskikh kommunal'nykh otkhodov. [Biotechnology and microbiology of anaerobic processing of organic municipal waste]. Ed. A.N. Nozhevnikova, A.Iu. Kallistov, Iu.V. Litti, M.V. Kevbrin. Moscow, 2016, 320 p. (in Russ.).

Vavilin V.A. Mikrobiologiia, 2010, vol. 79, no. 3, pp. 352–359. (in Russ.).

Korolev S.A., Maikov D.V. Komp'iuternye issledovaniia i modelirovanie, 2012, vol. 4, no. 1, pp. 131–141. (in Russ.).

Vavilin V.A. Priroda, 2008, no. 11, pp. 14–19. (in Russ.).

Monod J. Annual Reviews of Microbiology, 1949, vol. 3, pp. 371–394.

Yano T., Nakahara T., Kamiyama S., Yamada K. Agricultural and Biological Chemistry, 1966, vol. 30, no. 1, pp. 42–48.

Gaden E.L. Journal of Biochemical and Microbiological Technology and Engineering, 1959, vol. 1, no. 4, pp. 413–429.

Shein E.V., Goncharov V.M. Agrofizika. [Agrophysics]. Moscow, 2006, 400 p. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.