INVESTIGATION OF THE PROCESS OF OBTAINING THE TALL OIL BY LIGNIGN PHASE THERMAL EFFICIEN-CY AND EVALUATING THE CONFORMITY OF ITS QUALITY WITH THE REQUIREMENTS OF STANDARD-SETTING DOCUMENTS

Abstract

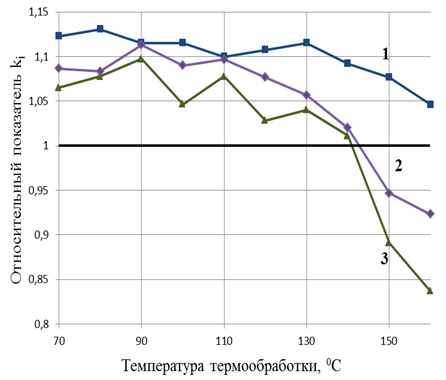

The main problem of industrial methods of production of tall oil is significant losses of the finished product with the waste of production – the lignin phase. It is a stable emulsion of the oil-in-water type, stabilized by lignin. Traditional ways to reduce the loss of tall oil by destroying the lignin phase are associated with a number of difficulties and in industrial practice are almost not currently used. In the present work, in order to increase the yield of tall oil when it is separated from the sulphate soap, a method for breaking the emulsion by heat treatment is proposed. The effect of the heat treatment temperature on the yield of tall oil from the lignin phase was studied. Optimum in relation to the yield of tall oil from the lignin phase is the temperature-time mode of heat treatment. It is shown that, under the optimal regime, the loss of tall oil with waste is reduced by 80%. Based on the results of the studies, a variant of the mechanism of changes occurring with components of the lignin phase during heat treatment is proposed. The composition of the components of the product after heat treatment at different temperatures has been studied. The values of the quality indicators of the obtained tall oil were established and their compliance with the requirements of the standard-setting documents in force in the territory of Russia was assessed. It was noted that all the parameters of the oil obtained during heat treatment correspond to the values established in the normative documents at the processing temperature from 100 to 140 °С. Based on the results of work, the heat treatment mode optimized for yield and quality of tall oil is proposed.

Downloads

Metrics

References

Sokolov O.M., Tret'iakov S.I., Glukhanov A.A. Lesokhimiia i organicheskii sintez. [Wood chemistry and organic synthesis]. Syktyvkar, 1998, pp. 85–86. (in Russ.).

Selianina S.B., Tel'tevskaia S.E., Afanas'ev S.I. Khimiia i tekhnologiia rastitel'nykh polimerov. [Chemistry and Tech-nology of Plant Polymers]. Syktyvkar, 2000, pp. 92–96. (in Russ.).

Selivanova N.V. Vliianie lignina i destabiliziruiushchikh dobavok na protsess razdeleniia faz pri poluchenii tallovogo masla: dis. ... kand. khim. nauk. [Effect of lignin and destabilizing additives on the phase separation process in the pro-duction of tall oil: dis. ... cand. chem. sciences]. Arkhangel'sk, 2005, 127 p. (in Russ.).

Bogdanovich N.I., Vladimirova T.M., Kutakova N.A., Tret'iakov S.I. Kontrol' i upravlenie kachestvom leso-khimicheskoi produktsii. [Control and quality management of wood chemical products]. Arkhangel'sk, 2013, 172 p. (in Russ.).

Golovin A.I., Trofimov A.N., Uzlov G.A. i dr. Lesokhimicheskie produkty sul'fattselliuloznogo proizvodstva. [Wood chemical products of sulfate-cellulose production]. Moscow, 1988, 288 p. (in Russ.).

Koverninskii I.N., Komarov V.I., Tret'iakov S.I., Bogdanovich N.I., Sokolov O.M., Kutakova N.A., Selianina L.I., D'iakova E.V. Kompleksnaia khimicheskaia pererabotka drevesiny. [Complex chemical processing of wood]. Arkhan-gel'sk, 2006, 374 p. (in Russ.).

Tret'iakov S.I., Glukhanov A.A. Ekologiia-99. [Ecology-99]. Vologda, 1999, pp. 54–57. (in Russ.).

Glukhanov A.A., Tret'iakov S.I. Noveishie issledovaniia v sovremennoi nauke: opyt, traditsii, innovatsii. [The latest re-search in modern science: experience, traditions, innovations]. Moscow, 2015, pp. 61–65. (in Russ.).

Glukhanov A.A., Tret'iakov S.I., Sokolov O.M. Okhrana okruzhaiushchei sredy i ratsional'noe ispol'zovanie prirodnykh resursov. [Environmental protection and rational use of natural resources]. Arkhangel'sk, 1998, pp. 85–91. (in Russ.).

Federal'nyi zakon RF «O standartizatsii v Rossiiskoi Federatsii» ot 29.06.2015 g. №162-FZ. [Federal Law of the Rus-sian Federation "On Standardization in the Russian Federation" dated 29.06.2015 No. 162-FZ]. Moscow, 2015, 48 p. (in Russ.).

TU 13-0281078-119-89. Maslo tallovoe syroe. Tekhnicheskie usloviia. [TU 13-0281078-119-89. Tall is crude oil. Technical specifications]. Gor'kii, 1989, 22 p. (in Russ.).

TU 2453-022-00253497-2005. Maslo tallovoe syroe. Tekhnicheskie usloviia. [TU 2453-022-00253497-2005. Tall is crude oil. Technical specifications]. St. Petersburg, 2005, 25 p. (in Russ.).

TU 2453-001-95601082-2008. Maslo tallovoe syroe. Tekhnicheskie usloviia. [TU 2453-001-95601082-2008. Tall is crude oil. Technical specifications]. Arkhangel'sk, 2008, 21 p. (in Russ.).

Vladimirova T.M., Tret'iakov S.I., Zhabin V.I., Koptelov A.E. Poluchenie i pererabotka tallovykh produktov. [Produc-tion and processing of tallow products]. Arkhangel'sk, 2008, 155 p. (in Russ.).

Mishin V.M. Upravlenie kachestvom: uchebnik dlia vuzov. [Quality Management: A Textbook for Universities]. Mos-cow, 2005, 463 p. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.