THE RESTORATION OF THE CAPILLARY-POROUS STRUCTURE OF CELLULOSE DURING HEAT TREATMENT AND PROCESSING BY MOISTURE

Abstract

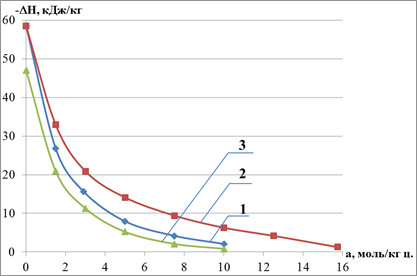

The influence heat treatment and processing by moisture on the hydrophilic properties of cellulose fibers. The possibility of using this treatment to restore the capillary-porous structure of cellulose, which had been lost during drying of pulp folder. Revealed peculiarities of the structure of cellulose when exposed of water vapor of high parameters of state. In the basis of understanding what is happening in this effect are the experimental data obtained by calorimetry and sorption. For the first time on the basis of experimental data the calculated thermodynamic functions of hydration of water by cellulose, subjected to hydrothermal effects in a wide range of humidity and temperature. On the basis of experimental data the calculated thermodynamic functions of sorption of water by cellulose obtained in the optimal regime of heat, processing by moisture (438 K, 4 min). These terms of processing indicate an increased content of active sites available for interaction with water. Prolonged exposure reduces hydrophilic properties of the treated pulp as a result of the process of secondary crystallization, which is typical for polymers in highly elastic condition. Consequently, in conditions of constant temperature and humidity can occur as the increase of hydrophilic properties of cellulose and hydrophobicity of the polymer depending on the conditions of hydrothermal influences.

Downloads

Metrics

References

Klark Dzh. Tekhnologiia tselliulozy. [Cellulose technology]. Moscow, 1983, 456 p. (in Russ.).

Roulend S. Voda v polimerakh. [Water in polymers]. Moscow, 1984, 555 p. (in Russ.).

Patent 94224 (RU). 2010. (in Russ.).

Baikova V.S., Osovskaia I.I. Izvestiia vuzov. Khimiia i khimicheskaia tekhnologiia, 2015, no. 6, pp. 74–78. (in Russ.).

Antonova V.S., Osovskaia I.I. XXIV Karginskie chteniia: tezisy dokladov. [XXIV Karginsky readings: abstracts of re-ports], Tver', 2017, pp. 10. (in Russ.).

Osovskaia I.I., Novoselov N.P., Baikova V.S. XX Mendeleevskii s"ezd po obshchei i prikladnoi khimii: tez. dokl. [XX Mendeleev Congress on General and Applied Chemistry: abstracts]. Ekaterinburg, 2016. С. 104. (in Russ.).

Drobosiuk V.M. Tekhnologiia izgotovleniia bumagi aerodinamicheskim sposobom. [Technology of paper making by aerodynamic method]. St. Petersburg, 2011, 56 p. (in Russ.).

Malinovskaia G.K., Litvinova L.V., Drobosiuk V.M. Tara i upakovka, 2011, no. 1, pp. 35–39. (in Russ.).

Patent 1779081 (RU). 1996. (in Russ.).

Fainberg E.Z., Mikhailov N.V., Papkov S.P. Vysokomolekuliarnye soedineniia, 1967, vol. 9, no. 7, pp. 1483–1488. (in Russ.).

Papkov S.P., Fainberg E.Z. Vzaimodeistvie tselliulozy i tselliuloznykh materialov s vodoi. [Interaction of cellulose and cellulose materials with water]. Moscow, 1976, 231 p. (in Russ.).

Osovskaia I.I., Poltoratskii G.M. Izvestiia vuzov. Lesnoi zhurnal, 1999, no. 1, pp. 101–106. (in Russ.).

Osovskaya I.I., Baikova V.S., Avakumova A.V. Effectiveness of ozone and chlorine dioxide treatment on the properties of sulfonated deciduous pulp // Fibre Chemistry. 2015. Vol. 47, N3. Pp. 161–165. DOI: 10.1007/s10692-015-9658-1

Baikova V.S., Osovskaia I.I., Poltoratskii G.M. Khimiya Rastitel'nogo Syr'ya, 2015, no. 1, pp. 175–180. DOI: 10.14258/jcprm.201501400

Knolle H., Jayme G. Papier, 1965, Bd. 19, H. 3, S. 106–110.

Akbarov Kh.I. Vestnic NUUZ, 2005, no. 5, pp. 3–7.

Akbarov Kh.I. Chemistry of natural compounds, 2004, no. 5, pp. 425.

Azarov V.I., Burov A.V., Obolenskaia A.V. Khimiia drevesiny i sinteticheskikh polimerov. [Chemistry of wood and synthetic polymers]. St. Petersburg, 2010, 624 p. (in Russ.).

Yarkulov A.Yu., Umarov B.S., Akbarov Kh.I. Austrian journal of technical and natural sciences, 2016, no. 11–12, pp. 85–88.

Larina V.N., Ur'iash V.F., Kokurina N.Iu., Novoselova N.V. Vestnik Kazanskogo gosudarstvennogo tekhnolo-gicheskogo universiteta, 2010, no. 1, pp. 168–171. (in Russ.).

Shevchuk M.O., Zil'bergleit M.A., Shishakov E.P. Khimiya Rastitel'nogo Syr'ya, 2013, no. 3, pp. 43–47. DOI: 10.14258/jcprm.1303043 (in Russ.).

Akim E.L. Obrabotka bumagi (osnovy khimii i tekhnologii obrabotki i pererabotki bumagi i kartona). [Paper pro-cessing (fundamentals of chemistry and technology of processing and processing paper and cardboard)]. M., 1979, 232 p. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.