REGULARITIES OF THE PROCESS OF PINE WOOD PEROXIDE DELIGNIFICATION IN THE PRESENCE OF SULFURIC ACID CATALYST

Abstract

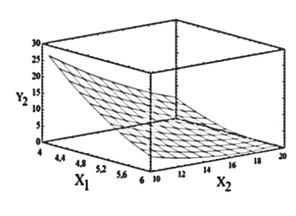

The known methods to obtain microcrystalline cellulose (MCC) from wood raw material is multi-stage and it is based on the integration of environmentally hazardous processes of pulping, bleaching and acid hydrolysis of cellulose amorphous part. The paper describes a one-stage catalytic method to obtain microcrystalline cellulose from pine wood based on peroxide delignification in acetic acid-water in the presence of a catalyst H2SO4. The optimal parameters of the process of pine wood peroxide delignification in the presence of 2% H2SO4 catalyst were determined by experimental and numerical methods: temperature – 100 °C, concentration H2O2 – 5 wt.%, CH3COOH – 25 wt.%, LWR 15, duration – 4 h. They provide a high yield of cellulose (45.2 wt.%) with a low content of residual lignin (1.0 wt%).The kinetic study of pine wood peroxide delignification at the temperature range 70-100 ºC was accomplished. The delignification process is described satisfactory by the first order equation in all temperature range. The rate constants vary between 0.08·10-4 and 2.15·10-4 s-1 and the activation energy is 90 kJmol-1. It was established by FTIR and XRD methods, that the cellulose, obtained from pine wood has the composition and structure similar to the commercial microcrystalline cellulose.

Downloads

Metrics

References

Autlov S.A., Bazarnova N.G., Kushnir E.Iu. Khimiia rastitel'nogo syr'ia, 2013, no. 3, pp. 33–41. (in Russ.).

Trachea D., Hussinb M.H., Chuinb C.T., Sabar S., Fazita M.R.N., Taiwo O.F.A., Hassan T.M., Haafiz M.K.M. International Journal of Biological Macromolecules, 2016, vol. 93, pp. 789–804. DOI: 10.1016/j.ijbiomac.2016.09.056.

Sixta H. Handbook of pulp, Wiley-VCH Verlag GmbH & Co, Weinheim, 2006, 1348 р.

Kuznetsov B.N., Kuznetsova S.A., Iatsenkova O.V., Danilov V.G. Poluchenie tselliulozy kataliticheskoi delignifikatsiei drevesiny peroksidom vodoroda: monografiia. [Production of cellulose by catalytic delignification of wood by hydrogen peroxide: monograph]. Krasnoiarsk, 2014, 146 p. (in Russ.).

Suchy M., Argyropoulos D. Tappi Journal, 2002, vol. 1, no. 2, pp. 1–18. DOI: 10.1021/bk-2001-0785.ch001.

Garyntseva N.V., Sudakova I.G., Kuznetsov B.N. Zhurnal Sibirskogo federal'nogo universiteta. Khimiia, 2018, no. 2, pp. 291–303. (in Russ.).

Kuznetsov B.N., Kuznetsova S.A., Danilov V.G., Yatsenkova O.V., Petrov A.V. Reaction Kinetics Mechanisms and Catysis, 2011, vol. 104, pp. 337–343. DOI: 10.1007/s11144-011-0354-8.

Sjöström E., Alen R. Analytical methods of wood chemistry. Pulping and papermaking, Berlin: Springer-Verlag, 1999, 318 p.

Kuznetsova S.A., Danilov V.G., Kuznetsov B.N., Yatsenkova O.V., Alexandrova N.B., Shambasov V.K., Pavlenko N.I. Chemistry for Sustainable Development, 2003, vol. 11, pp. 141–147.

Tappi standard T 222 Om-98. Acid-insoluble lignin in wood and pulp. Technical association of the pulp and paper industry, Atlanta, 1998, 5 p.

Obolenskaia A.V., El'nitskaia Z.P., Leonovich A.A. Laboratornye raboty po khimii drevesiny i tselliulozy. [Laboratory work on the chemistry of wood and cellulose]. Moscow, 1991, 321 p. (in Russ.).

Park S., Baker J.O., Himmel M.E., Parilla P.A., Jonson D.K. Biotechnology and Biofuels, 2010, vol. 3, p. 10.

Nepenin Iu.N. Tekhnologiia tselliulozy. Proizvodstvo sul'fatnoi tselliulozy. [Pulp technology. Sulphate pulp production]. Moscow, 1990, 600 p. (in Russ.).

Pen R.Z. Planirovanie eksperimenta v Statgraphics. [Experiment Planning in Statgraphics]. Krasnoiarsk, 2003, 246 p. (in Russ.).

Fan M., Dai D., Huang B. Fourier transform infrared spectroscopy for natural fibres. In: Salih Salih (ed) Fourier transform-materials analysis. Rijeka: In Tech, 2012, 365 p.

Xiang L.Y., Mohammed M.A.P., Baharuddin A.S. Carbohydrate Polymers, 2016, vol. 148, pp. 11–20. DOI: 10.1016/j.carbpol.2016.04.055.

Moran J.I., Alvarez V.A., Cyras V.P., Vazquez A. Cellulose, 2008, vol. 15, pp. 149–159. DOI: 10.1007/s10570-007-9145-9.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.