COMPARISON OF LAURUS NOBILIS EXTRACTS COMPOSITION OBTAINED BY MICROWAVE EXTRACTION, SUPERCRITICAL FLUID EXTRACTION AND STEAM DISTILLATION

UDC 665.525.74

Abstract

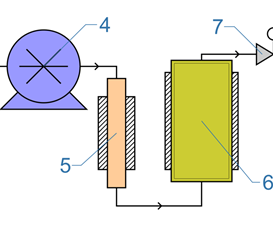

A comparison of chemical composition of bay laurel extracts obtained by microwave extraction, supercritical fluid extraction and steam distillation was performed. Microwave extraction and steam distillation were shown to give similar essential oils. Microwave extract contains more monoterpenoid components, especially hydrocarbons. Steam distillation oil contains more sesquiterpenoid compounds, mostly oxygenated. SFE extract composition differs substantially from the ones obtained by two other methods. According to GC-MS data they contain much more sesquiterpenoid components, namely sesquiterpene lactones. This makes SFE a perspective candidate for isolation of biologically active compounds from laurel leaves. However, apart from valuable compound SFE extracts also contain substantial amounts of waxes as well as large quantities of some non-volatile component undetectable via GC-MS. In order to implement SFE into the practice of laurel processing one has to develop an approach for the fractionation of SFE extracts allowing isolating sesquiterpene lactone enriched fraction.

Downloads

Metrics

References

Konovalov D.A., Nasuhova N.M., Pharm. Pharmacol., 2015,vol. 2, no. 2(3), pp. 23–33. DOI: 10.19163/2307-9266-2014-2-2(3)-23-33.

Prokopchuk D.I., Pokrovskiy O.I., Parenago O.O., Bagateliya S.A., Markoliya A.A., Pokryshkin S.A., Lunin V.V., Khimiya Rastitel'nogo Syr'ya, 2018, no. 3, pp. 169–177. (in Russ.). DOI: 10.14258/jcprm.2018033758.

Ustinovich K.B., Prokopchuk D.I., Pokrovskiy O.I., Parenago O.O., Lunin V.V. Russ. J. Phys. Chem. B, 2018, vol. 12, no. 8, pp. 1306–1309. DOI: 10.1134/S1990793118080134.

Babushok V.I., Zenkevich I.G., Chromatographia, 2009, vol. 69, no. 3–4, pp. 257–269. DOI: 10.1365/s10337-008-0872-3.

Flamini G., Tebano M., Cioni P.L., Ceccarini L., Ricci A.S., Longo I.,J. Chromatogr. A, 2007,vol. 1143, no. 1–2, pp. 36–40. DOI: 10.1016/j.chroma.2007.01.031.

Peris I., Blázquez M.A., Int. J. Food Prop., 2015, vol. 18, no. 4, pp. 757–762. DOI: 10.1080/10942912.2014.906451.

Kilic A., Hafizoglu H., Kollmannsberger H., Nitz S., J. Agric. Food Chem., 2004,vol. 52, no. 6, pp. 1601–1606. DOI: 10.1021/jf0306237.

Caredda A., Marongiu B., Porcedda S., Soro C., J. Agric. Food Chem., 2002,vol. 50, no. 6, pp. 1492–1496. DOI: 10.1021/jf0108563.

Marzouki H., Khaldi A., Chamli R., Bouzid S., Piras A., Falconieri D., Marongiu B.,Nat. Prod. Res., 2009, vol. 23, no. 3, pp. 230–237. DOI: 10.1080/14786410801976400.

Santoyo S., Lloría R., Jaime L., Ibañez E., Señoráns F.J., Reglero G.,Eur. Food Res. Technol., 2006,vol. 222, no. 5–6, pp. 565–571. DOI: 10.1007/s00217-005-0027-9.

Marzouki H., Piras A., Marongiu B., Rosa A., Dessì M., Molecules, 2008, vol. 13, no. 8, pp. 1702–1711. DOI: 10.3390/molecules13081702.

El S.N., Karagozlu N., Karakaya S., Sahin S., Food Nutr. Sci., 2014, vol. 5, no. 2, pp. 97–106. DOI: 10.4236/fns.2014.52013.

Bayramoglu B., Sahin S., Sumnu G., Sep. Sci. Technol., 2009, vol. 44, no. 3, pp. 722–733. DOI: 10.1080/01496390802437271.

Lavrent'yev V.I., Markoliya A.A., Bagateliya S.A., Taniya R.G., Khimiya Rastitel'nogo Syr'ya, 2015, no. 2, pp. 85–96. (in Russ.). DOI: 10.14258/jcprm.201502401.

Methyl eugenol. URL: https://www.chemicalbook.com/ChemicalProductProperty_US_CB8198972.aspx

Eugenol. URL: https://www.chemicalbook.com/ChemicalProductProperty_EN_CB7208326.htm

Di Leo Lira P., Retta D., Tkacik E., Ringuelet J., Coussio J.D., van Baren C., Bandoni A.L.,Ind. Crops Prod., 2009, vol. 30, no. 2, pp. 259–264. DOI: 10.1016/j.indcrop.2009.04.005.

Pokrovskiy O.I., Prokopchuk D.I., Kostenko M.O., Ustinovich K.B., Parenago O.O., Lunin V.V., Russ. J. Phys. Chem. B, 2018, vol. 12, no 7, pp. 1176–1181. DOI: 10.1134/S1990793118070096.

Copyright (c) 2019 Khimiya Rastitel'nogo Syr'ya (Chemistry of plant raw material)

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.