STRUCTURE AND SORPTION PROPERTIES OF ACTIVATED CARBON BASED ON PINE BARK CARBONIZATS

UDC 661.832.2:544.723

Abstract

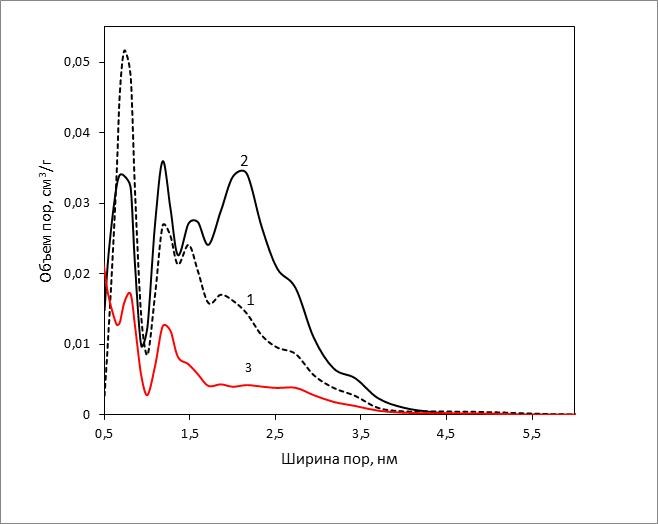

The dates about effect of temperature of carbonizats obtaining from pine bark on evolution of a porous structure and sorption properties of the activated carbons, synthesized by the method of thermoalkaline activation in the presence of КОН were presented. It was determined, that for preparation of activated carbons with the greatest specific surface (1421 and 1655 m2/g) and micropores volume (0.58 и 0.71 sm3/g) pine bark carbonizats reasonable to obtain at temperature 300 and 400 °С correspondingly. The correlation of a iodine sorption with volume of micropores width 0.73–3.0 nm (R2=0.964) and a methylene blue sorption with volume of micropores width 0.84–2.0 nm (R2=0.995), which present in the activated carbons structure, was established. It was shown, that low capacity of the activated carbons to vitamin B12 sorption determine by low mesopores volume with width ≥5 nm (no more than 0.0014 sm3/g). It was shown, that the activated carbon based on carbonizat obtained at 400 °С demonstrates a maximal sorption capacity to a iodine and a methylene blue (1.57 g/g и 697.1 mg/g correspondingly), that in 1.4 and 2.7 times exceeds the dates of an industrial activated carbon for medical purposes.

Downloads

Metrics

References

Kuznetsov B.N., Chesnokov N.V., Ivanov I.P., Veprikova Ye.V., Ivanchenko N.M. Zhurnal sibirskogo federal'nogo universiteta. Khimiya, 2015, vol. 8, no. 2, pp. 232–255. DOI: 10.17516/1998-2836-2015-8-2-232-255. (in Russ.).

Pasztory Z., Mohacsine I.R., Gorbacheva G., Borcsok Z. BioResources, 2016, vol. 11, no. 3, pp. 7859–7888. DOI: 10.15376/biores.11.3.Pasztory.

Amerkhanova Sh.K., Shlyapov R.M., Uali A.S. Colloids and Surfaces A: Physicochemical and Enginering Aspects, 2017, vol. 532, no. 5, pp. 36–40. DOI: 10.1016/j.colsurfa.2017.07.015.

Morozov A.S., Bessonov I.V., Nuzhdina A.I., Pisarev V.M. Obshchaya reanimatologiya, 2016, vol. 12, no. 6, pp. 82–107. DOI: 10.15360/1813-9779-2016-6-82-107. (in Russ.).

Zellner T., Prasa D., Farber E., Hoffmann-Walbeck P., Genser D., Eyer F. Deutsches Arzteblatt Int., 2019, vol. 116, no. 18, pp. 311–317. DOI: 10.3238/arztebl.2019.0311.

Yakimova T.I., Mamchenko A.Ye., Koganovskiy A.M. Khimiya i tekhnologiya vody, 1979, vol. 1, no. 1, pp. 26–29. (in Russ.).

Raposo F., De La Rubia M.A., Borjia R. J. of Hazardous Materials, 2009, vol. 165, no. 1–3, pp. 291–299. DOI: 10.1016/j.jhazmat.2008.09.106.

Zhang J., Zhang W., Zhang Y. BioResources, 2015, vol. 10, no. 1, pp. 566–574.

Luo Y., Street J., Steele P., Entsminger E., Guda V. BioResources, 2016, vol. 11, no. 4, pp. 10433–10447. DOI: 10.15376/biores.11.4.10433-10447/

Zhao W., Luo L., Wang H., Fan M. BioResources, 2017, vol. 12, no. 1, pp. 1246–1262. DOI: 10.15376/biores.12.1.1246-1262.

Ivanov I.P., Veprikova Ye.V., Chesnokov N.V. Zhurnal sibirskogo federal'nogo universiteta. Khimiya, 2019, vol. 12, no. 3, pp. 423–433. DOI: 10.17516/1998-2839-0139. (in Russ.).

Veprikova Ye.V., Ivanov I.P., Chesnokov N.V., Kuznetsov B.N. Khimiya rastitel'nogo syr'ya, 2019, no. 3, pp. 325–333. DOI: 10.14258/jcprm2019035180. (in Russ.).

Galvano F., Pietri A., Bertuzzi T., Fusconi G., Galvano M., Piva A., Piva G. Journal of Food Protection, 1996, vol. 59, no. 5, pp. 551–554. DOI: 10.4315/0362-028X-59.5.551.

Miyahara M., Vinu A. Thin Solid Films, 2006, vol. 499, no. 1–2, pp. 13–18. DOI: 10.1016/j.tsf.2005-07.046.

Miyahara M., Vinu A., Ariga K. Materials science and Engineering: C, 2007, vol. 27, no. 2, pp. 232–236. DOI: 10.1016/j.msec.2006.05.012.

Burchacka E., Lukaszewicz M., Kulazynski M. J. Bioorganic Chemistry, 2019, vol. 93, pp. 1–7. DOI: 10.1016/j.bioorg.2019.02.029.

Siipola V., Tamminen T., Kalli A., Lahti R., Romar H., Rasa K., Keskinen R., Hyvaluoma J., Hannuba M., Wikberg H. BioResources, 2018, vol. 13, no. 3, pp. 5976–6002. DOI: 10.15376/biores.13.3.5976-6002.

Ivanov I.P., Mikova N.M., Lutoshkin M.A., Chesnokov N.V., Kuznetsov B.N. Zhurnal sibirskogo federal'nogo uni-versiteta. Khimiya, 2017, vol. 10, no. 3, pp. 390–400. DOI: 10.17516/1998-2836-0035. (in Russ.).

Landers J., Gor G.Yu., Neimark A.V. Colloids and Surfaces. A: Physicochemical and Engineering Aspects, 2013, vol. 437, pp. 3–32. DOI: 10.1016/j.colsurfa.2013.01.007

Morozova A.A., Lyga L.K., Yermolenko I.N. Zhurnal prikladnoy khimii, 1989, no. 12, pp. 2777–2781. (in Russ.).

Markelov D.A., Nitsak O.V., Gerashenko T.T. Pharmaceutical Chemistry Journal, 2008, vol. 42, no. 7, pp. 405–408.

Chen Y. Synthesis, characterization and mechanistic studies of Biomolecules @ mesoMOFs. URL: http://scholarcommons.ust.edu/etd/5199 (22.05.2018).

Copyright (c) 2020 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.