ABOUT THE REASONS FOR THE CHANGE IN THE MECHANICAL PROPERTIES OF PAPER ASHLESS FILTERS DURING THEIR PROCESSING IN A UNIPOLAR CORONA DISCHARGE

UDC 676.26

Abstract

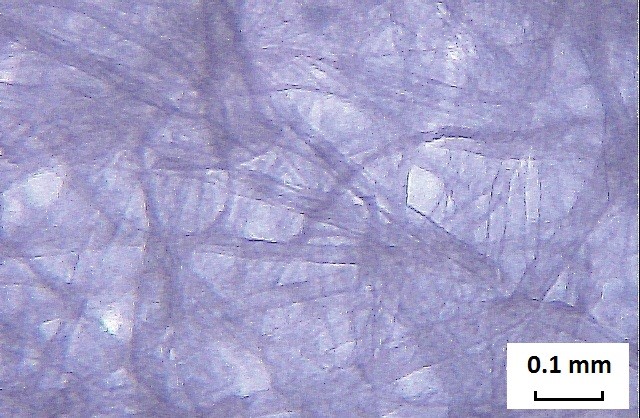

The article presents the study results of the structure and properties of paper ashless filters "Blue tape". It is shown that the "Blue tape" filter paper has a fairly high density with a relatively small number and size of voids (pores) between the fibers. When processing filters in the corona discharge field, an increase in their mechanical properties by 3.5–6% is observed, this is mainly due to the strengthening of the interfiber bond forces. The implementation of increased electrostatic bonding forces in the sheet structure leads to an increase in the resistance to the external tensile force necessary to break the paper filter. The observed dependences are associated with the orientation and ordering of the pulp and paper material structural elements, with an increase in the potential of the double electric layer on the fibers surface under the charge action carriers injected into the paper volume from the corona discharge and with the formation of a hetero charge due to the orientation of the polar cellulose groups and macromolecule segments during electreting. This is confirmed by the increase in the ζ – potential of the fibers of filters during processing in a negative corona discharge - it was found that the zeta – potential value of electret ashless filters is 18% higher than for the initial ones. The achieved results of increasing the ashless filters physico- mechanical properties will increase the efficiency of their use.

Downloads

Metrics

References

Kanarskiy A.V. Fil'troval'nyye vidy bumagi i kartona dlya promyshlennykh tekhnologicheskikh protsessov. [Filter papers and cardboard for industrial technological processes]. Moskow, 1991, 272 p. (in Russ.).

Flyate D.M. Svoystva bumagi. [Paper properties]. Moscow, 1986, 680 p. (in Russ.).

Imani R., Talaiepour M., Dutta J., Ghobadinezhad M.R., Hemmasi A.H., Nazhad M.M. BioResources, 2011, vol. 6, is-sue 1, pp. 891–900.

Salminen L.I. Journal of Pulp and Paper Science, 1996, vol. 22, issue 10, pp. J402–J407.

Haslach Jr. H.W. Composites Part B: Engineering, 1996, vol. 27, issue 1, pp. 25–33. DOI: 10.1016/1359-8368(95)00003-8.

Delgado-Fornué E., Contreras H.J., Toriz G., Allan G.G. Journal of Adhesion Science and Technology, 2010, vol. 25, is-sue 6–7, pp. 597–614. DOI: 10.1163/016942410X530951.

Dul'kin D.A., Spiridonov V.A., Komarov V.I., Blinova L.A. Svoystva tsellyuloznykh volokon i ikh vliyaniye na fiziko-mekhanicheskiye kharakteristiki bumagi i kartona. [Properties of cellulose fibers and their effect on the physical and me-chanical characteristics of paper and cardboard]. Arkhangelsk, 2011, 176 p. (in Russ.).

Fornué E.D., Allan G.G., Quiñones H.J.C., González G.T., Saucedo J.T. O Papel, 2011, vol. 72, issue 9, pp. 85–90.

Ivanova Ye.I., Smolin A.S., Zvonareva T.K., Ivanov-Omskiy V.I. Khimiya rastitel'nogo syr'ya, 2015, no. 1, pp. 181–185. DOI: 10.14258/jcprm.201501400. (in Russ.).

Kozhevnikov S.YU., Koverninskiy I.N. Khimiya rastitel'nogo syr'ya, 2012, no. 3, pp. 197–202. (in Russ.).

Smolin A.S., Bisal'ski M., Shabel' S., Shabiyev R.O. Khimiya rastitel'nogo syr'ya, 2011, no. 3, pp. 183–192. (in Russ.).

Perepelkina A.A., Galikhanov M.F., Musina L.R. Surface Engineering and Applied Electrochemistry, 2015, vol. 51, no. 2, pp. 138–142. DOI: 10.3103/S1068375515020118.

Nazmiyeva A.I., Galikhanov M.F., Musina L.R. Izvestiya vuzov Lesnoy zhurnal, 2017, no. 5, pp. 150–158. DOI: 10.17238/issn0536-1036.2017.5.150.

Musina L.R., Galikhanov M.F., Volkova S.V. Problemy mekhaniki tsellyulozno-bumazhnykh materialov: materialy IV mezhdunarodnoy nauchno-tekhnicheskoy konferentsii. [Problems of the mechanics of pulp and paper materials: materials of the IV international scientific and technical conference]. Arkhangelsk, 2017, pp. 114–119. (in Russ.).

Musina L.R., Galikhanov M.F., Nafikova A.R. Vestnik tekhnologicheskogo universiteta, 2017, vol. 20, no. 6, pp. 48–50. (in Russ.).

Musina L.R., Galikhanov M.F. Khimiya rastitel'nogo syr'ya, 2017, no. 2, pp. 155–161. DOI: 10.14258/jcprm.2017021782. (in Russ.).

Plopeanu M.C., Notingher P.V., Dumitran L.M., Tabti B., Antoniu A., Dascalescu L. IEEE Transactions on Dielectrics and Electrical Insulation, 2011, vol. 18, issue 5, pp. 1393–1400. DOI: 10.1109/TDEI.2011.6032807.

Xiao H., Song Y., Chen G. Journal of Electrostatics, 2014, vol. 72, issue 4, pp. 311–314. DOI: 10.1016/j.elstat.2014.05.006.

Yu B., Han J., Sun H., Zhu F., Zhang Q., Kong J. Polymer Composites, 2015, vol. 36, issue 2, pp. 264–271. DOI: 10.1002/pc.22939.

Wang Y., Lin Z., Zhang W. Building and Environment, 2020, vol. 179, 106962. DOI: 10.1016/j.buildenv.2020.106962.

Shabiyev R.O., Smolin A.S. Analiz elektrokineticheskikh parametrov bumazhnoy massy. [Analysis of electrokinetic pa-rameters of paper pulp]. 2012, 80 p. (in Russ.).

Belen'kiy D., Balakhanov D., Lesnikov Ye. Analitika, 2017, no. 3, pp. 82–89. (in Russ.).

Komarov V.I., Galkina L.A., Laptev L.N. and others. Tekhnologiya tsellyulozno-bumazhnogo proizvodstva: v 3 t. T. II. Proizvodstvo bumagi i kartona. CH. 2. osnovnyye vidy i svoystva bumagi, kartona, fibry i drevesnykh plit. [Technology of pulp and paper production: in 3 vol. Vol. II. Production of paper and cardboard. Part 2. main types and properties of paper, cardboard, fiber and wood-based panels]. St. Petersburg, 2006, 499 p.

Vertyachikh I.M., Voronezhtsev YU.I., Gol'dade V.A., Pinchuk L.S. Plasticheskiye massy, 1986, no. 3, pp. 30–32. (in Russ.).

Gol'dade V.A. Mekhanika kompozitnykh materialov, 1998, vol. 34, no. 2, pp. 153–162. (in Russ.).

Mochalova E.N., Limarenko N.A., Galikhanov M.F., Deberdeev R.Ya. Polymer Science, Series D, 2016, vol. 9, no. 4, pp. 396–401. DOI: 10.1134/S1995421216040122.

Yovcheva Т. Corona charging of synthetic polymer films. New York, 2010. 60 p.

Kestelman V.N., Pinchuk L.S., Goldade V.A. Electrets in Engineering: Fundamentals and Applications. Boston-Dordrecht-London, 2000. 281 p.

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.