CURRENT STATE AND PROSPECTS FOR IMPROVING THE PROCESS OF MILLING FIBROUS SEMI-FINISHED HIGH CONCENTRATION PROCESSES (REVIEW)

UDC 676.15

Abstract

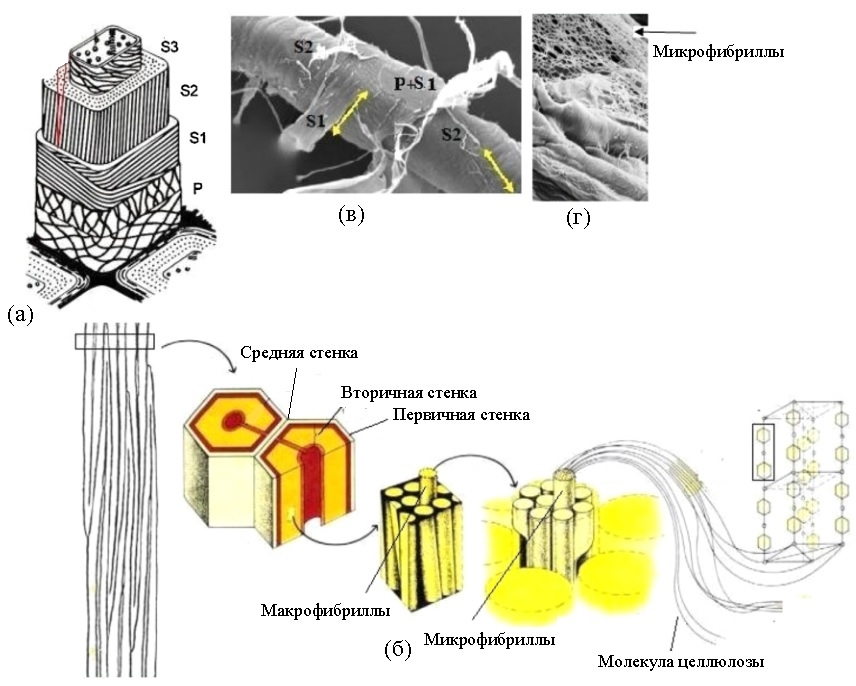

There is presented a review of scientific literature characterizing the main directions of modern research of the process of grinding of fibrous semi-finished products of high consistence. Theoretical approaches are described in the study of qualitative parameters of pulp during its processing in knife grinding machines.

Researchers note an increase in the paper-forming properties of the pulp and the physical and mechanical characteristics of the finished product. This paper provides an overview of experimental studies of the high consistence pulp milling process. The effect of high consistence mass grinding intensity on the quality of the finished product is considered, the nature of fiber development when grinding high and low consistence mass is compared. Experimental studies show that an increase in the intensity of exposure when grinding a high consistence mass leads to a decrease in the tensile energy absorption index, and a decrease in the deformation of the paper sheet is also observed with an increase in the grinding intensity. With an increase in the pulp c consistence, a change in the degree of delamination, internal and external fibrillation of the fiber wall is observed. The high-consistence pulp milling process is accompanied by higher specific energy consumption compared to low- consistence pulp milling, but observations at the fiber wall level show a more developed external specific surface area.

This review of the scientific literature will serve as a basis for further research on the grinding of high consistence fibrous materials.

Downloads

Metrics

References

Kerekes R.J. Nordic Pulp and Paper Research journal, 2011, pp. 14–20.

Leider P.J., Nissan A.H. TAPPI, 1977, pp 85–101.

Alashkevech Yu.D. Gidrodinamicheskiye yavleniye pri razmole voloknistykh polufabrikatov v nozhevykh razma-lyvayushchikh mashinakh: monografiya. [Hydrodynamic phenomenon during the grinding of fibrous semi-finished products in knife grinding machines: monograph]. Krasnoyarsk, 2000, 248 p. (in Russ.).

Miles K.B., May W.D. Pulp Paper Scientific Journal, 1990, pp. 63–72.

Miles K.B. Paperi ja Puu, 1991, pp. 852–857.

Wultsch F., Flucher W. Papier, 1958, pp. 334–342.

Brecht W. Papier, 1966, pp 4–14.

Kerekes R.J. Pulp Paper Scientific Journal, 2010, pp. 1–6.

Kerekes R.J., Senger J.J. Pulp Paper Scientific Journal, 2006, pp. 1–8.

Lumiainen J. Tappi Papermakers Conference, 1990, pp. 269–278.

Gurnagul N., Shuohui J., Shallhorn P. Article in Appita Annual Conference, Appita: Technology, Innovation, Manufac-turing, Environment, 2005, pp. 379–386.

Milles K.B. Proc. The Marcus Wallenberg Foundation Symposia, 1998, pp. 20–30.

Alashkevich Yu.D. Osnovy teorii gidrodinamicheskoy obrabotki voloknistykh materialov v razmol'nykh mashinakh: dis. … doktora tekhnicheskikh nauk. [Fundamentals of the theory of hydrodynamic treatment of fibrous materials in grinding machines: dis. … Doctors of technical sciences]. Krasnoyarsk, 1986, 361 p. (in Russ.).

Nabiyeva A.A. Otsenka vliyaniya i sovershenstvovaniye osnovnykh tekhnologicheskikh parametrov nozhevykh razma-lyvayushchikh mashin: dis. … kandidata tekhnicheskikh nauk. [Assessment of the influence and improvement of the main technological parameters of knife grinding machines: dis. … Candidate of technical sciences]. Krasnoyarsk, 2004, 177 p. (in Russ.).

Kovalev V.I. Razmol voloknistykh polufabrikatov pri razlichnom kharaktere postroyeniya risunka nozhevoy garnitury: dis. … kandidata tekhnicheskikh nauk. [Grinding of fibrous semi-finished products with a different nature of the con-struction of the pattern of the knife set: dis. … Candidate of technical sciences]. Krasnoyarsk, 2007, 176 p. (in Russ.).

Goncharov V.N. Teoreticheskiye osnovy razmola voloknistykh materialov v nozhevykh mashinakh: dis. … doktora tekhnicheskikh nauk. [Theoretical foundations of refining fibrous materials in knife machines: dis. … Doctors of tech-nical sciences]. Leningrad, 1990, 474 p. (in Russ.).

Legotskiy S.S., Laptev L.N. Razmol bumazhnoy massy. [Pulp grinding]. Moscow, 1981, 83 p. (in Russ.).

Laptev L.N. Issledovaniye razmola otkhodov drevesno-massnogo proizvodstva na diskovoy mel'nitse: dis. … kand. tekh. nauk. [Investigation of the grinding of wood-pulp production waste in a disk mill: dis. ... Cand. tech. sciences]. Leningrad, 1969, 168 p. (in Russ.).

Khalandovskiy I.N., Laptev L.N., Gensler T.A. Trudy VNIIBa, 1973, pp. 109–116. (in Russ.).

Rosenfeld K., Hoffman I. Das papier, 1965, pp. 58 66.

Kurdin J.A. Doshi Assoc. Sem. Refining Chem. Pulps, Appleton. 1986, p. 15.

Herbert W., Marsh P.G., Harbron D.L. Paper Trade Journal, 1967, vol. 1551, pp. 42–48.

El Hosseiny F. Pulp and Paper Sci., 1994, vol. 20(12), pp. 366–370.

Dinesh F., Gorski D., Sabourin M., Geoffrey D. Holzforschung, 2013, pp. 735–745.

Kure K.A. On the relationship between process input variables and fibre characteristics in thermomechanical pulping: Doctoral thesis, Trondheim, 1999, 99 p.

Gorski D., Morseburg K., Axelsson P., Engstrang P. Nord and paper research journal, 2011, pp. 1–47.

Hill J., Sabourin M., Aichinger J., Johansson L., Gorski D., Axelsson P. 7th International Fundamental Mechanical Pulp, Nanjing, 2010, p. 164.

Johansson L., Hill J., Gorski D., Axelsson P. Nord and paper research journal, 2011, pp. 31–46.

Sabourin M., Xu E., Cort B., Boileau I., Waller A. Pulp and paper, 1997, pp. 111–118.

Gorski D., Morseburg K., Olson J., Luukkonen A. Nord and paper research journal, 2012, pp. 872–881.

Fernando D., Daniel G. Tappi journal, 2010, pp. 47–55.

Blanchette R.A., Akhtar M., Attridge M.C. Tappi journal, 1992, pp. 121–124.

Fernando D., Muhić D., Engstrand P., Daniel G. Holzforschung, 2012, pp. 467–475.

Eriksen O. High-frequency pressure measurements in the refining zone of a high-consistency refiner: Doctoral thesis, Norwegian University of Science and Technology, 2003, 303 p.

May W.D., McRae M.R., Miles K.B., Lunan W.E. Journal of Pulp and Paper Science, 1998, pp. 47–53.

Peakes D.E. Tappi, 1967, vol. 50, p. 38A.

Olender D., Wild P., Byrnes P., Ouellet D., Sabourin M. Journal of Pulp and Paper Science, 2007, pp. 163–171.

Heymer J.O., Olson J.A., Kerekes R.J. Nordic Pulp & Paper Research Journal, 2011, pp. 283–287.

Eriksen O., Gregersen O., Krogstad P-A. Journal of Pulp and Paper Science, 2005, pp. 458–467.

Senger J.J., Ouellet D. Journal of Pulp and Paper Science, 2002, pp. 364–369.

Hietanen S. Paperi Puu, 1991, pp. 52–61.

Gorski D., Mörseburg K., Axelsson P., Engstrand P. Nord and paper research journal, 2011, pp. 47–63.

Gorski D., Mörseburg K., Johansson L. Nord and paper research journal, 2011, pp. 232–247.

Gorski D., Olson J., Luukkonen A. Appita journal, 2012, pp. 244–249.

Gorski D., Johansson L., Engstrand P. Holzforschung, 2012, pp. 275–281.

Kang T., Paulapuro H. Pulp and Paper, 2006, pp. 51 54.

Hartman R.R. Mechanical Treatment of Pulp Fibres for Property Development: Doctoral Thesis, Appleton, 1984, 127 p.

Braaten K.R. Pulp and paper, 2000, vol. 101, pp. 122–127.

Miles K., Karnis A. Tappi Journal, 1991, vol. 74(1), pp. 157–164.

Wistara N., Young R. Physical and chemical properties of pulps, 1999, pp. 291–324.

Sjöberg J., Höglund H. International mechanical pulping conference, Minnesota, 2007, 11 p.

Kang T., Paulapuro H. The 2004 Progress in Paper Physics Seminar. NTNU and PFI, Trondheim, 2004, pp. 11–13.

Szwarcztajn E., Przybysz K. Cellulose chemistry technology, 1972, pp. 223–238.

Hartler N. Nordic Pulp and Paper Research Journal, 1995, no. 1, pp. 4–7.

Genco J.M. Tappi Pulping Conference, Atlanta, 1999, pp. 57–96

Stone J.E., Scallan A.M., Abrahamson B. Svensk Papperstidn, 1968, pp. 687–694.

Olejnik K. BioResources, 2013, vol. 8, p. 3212.

Loijas M. Factors affecting the axial force in low-consistency refining, Tampere, 2010, 32 p.

Htun M., Fellers C. Tappi, 1982, vol. 65(4), p. 113.

Nanko H., Ohsawa J. Papermaking Raw Materials: Transactions of the Ninth Fundamental Research, Mechanical En-gineering Publications, London, 1989, pp 783–830.

Retulainen E. The Role of Fibre Bonding in Paper Properties: Doctoral Thesis, Espoo, 1997, 312 p.

Giertz H. International Symposium on Fundamental Concepts of Refining Institute of Paper Chemistry, Appleton, 1980, pp. 324–330.

Page D.H. Svensk Papperstidn, 1985, pp. 30–35.

Page D.H., Seth R.S., Jordan B.D., Barbe M.C. Papermaking Raw Materials: Transactions of the Eighth Fundamental Research, London, 1985, pp. 183–227.

Kozhukhov V.A., Alashkevich Yu.D. Khimiya rastitel'nogo syr'ya, 2009, no. 2, pp. 153–155. (in Russ.).

Kozhukhov V.A., Alashkevich Yu.D., Kovalev V.I. Izvestiya VUZov. Lesnoy zhurnal, 2014, no. 2, pp. 94–100. (in Russ.).

Korda I., Libnar Z., Prokop I. Razmol bumazhnoy massy: ucheb. dlya vuzov. [Grinding paper pulp: textbook for uni-versities]. Moscow, 1967, 421 p. (in Russ.).

Alashkevich Yu.D., Reshetova N.S. Teoriya i konstruktsiya mashin i oborudovaniya otrasli: ucheb. posobiye. [Theory and design of machinery and equipment in the industry: textbook allowance]. Krasnoyarsk, 2015, 317 p. (in Russ.).

Pakhar' D.V., Kovalev V.I., Alashkevich Yu.D. Khimiya rastitel'nogo syr'ya, 2009, no. 1, pp. 167–172. (in Russ.).

Nabiyeva A.A., Kovalev V.I., Alashkevich Yu.D. Khimiya rastitel'nogo syr'ya, 2009, no. 3, pp. 169–172. (in Russ.).

Ivanov S.N. Tekhnologiya bumagi. [Paper technology]. Moscow, Leningrad, 1970, 720 p. (in Russ.).

Laptev L.N., Khalandovskiy I.N. Novoye v tekhnologii razmola massy na diskovykh mel'nitsakh: sbornik referatov. [New in the technology of pulp grinding in disk mills: a collection of abstracts]. Leningrad, 1970, pp. 157–171. (in Russ.).

Sakharov S.M. Razmol massy vysokoy kontsentratsii: sbornik referatov po zarubezhnym materialam. [Grinding the mass of high concentration: a collection of abstracts on foreign materials]. Moscow, 1971, 64 p. (in Russ.).

Matveyev B.P. Issledovaniye osnovnykh faktorov protsessa razmola sul'fatnoy nebelenoy tsellyulozy v disko-voy mel'nitse pri vysokoy kontsentratsii: dis. … kandidata tekhnicheskih nauk. [Investigation of the main factors of the pro-cess of grinding unbleached sulfate cellulose in a disc mill at high concentration: dis. … Candidate of technical sciences]. Leningrad, 1971, 112 p. (in Russ.).

Vasil'yev A.A. Optimizatsiya parametrov nozhevoy garnitury dlya razmola massy vysokoy kontsentratsii: dis. … kand. tekh. nauk. [Optimization of the parameters of the knife set for grinding a mass of high concentration: dis. ... Cand. tech. sciences]. Leningrad, 1983, 225 p. (in Russ.).

Savitskiy Ye.Ye., Khalandovskiy I.M., Laptev L.N, Byvshev A.V. Sbornik trudov VNIITSB, 1976, pp. 18–21. (in Russ.).

Copyright (c) 2020 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.