OBTAINING AN ANALYTICAL DEPENDENCE OF THE STRENGTH PROPERTIES OF PAPER ON THE PAPER-FORMING PARAMETERS OF THE FIBROUS MASS

UDC 676.15

Abstract

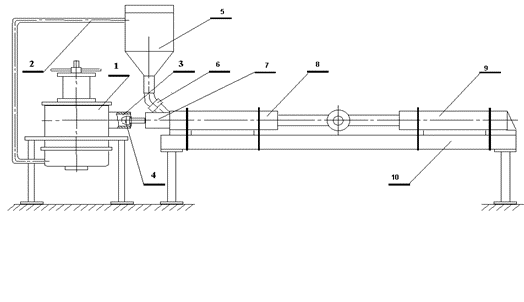

Wood is of great practical importance as a starting material for the recovery of cellulose. Wood plays not only an important economic role as a building and finishing material, but is also one of the cheapest and most widely used raw materials for the industrial production of cellulose vines. In turn, the grinding equipment serves to divide the cellulosic materials into fibers, from the grinding of the fibers and imparting certain properties to them. One of the most important properties of paper is mechanical strength. The standard provides for certain requirements for different types of paper, depending on the consumer conditions for the use of finished products. Durability of paper is determined by various indicators characterizing: paper resistance to a gap, breakdown, tear, an anguish, lengthening to a gap. In this work, the role of milling of fibrous materials in the general preparatory cycle of pulp and paper production is considered, the advantages of knife-free milling are presented, the factors determining the strength of paper are considered, functional dependencies of the main physical and mechanical characteristics of the finished product on the complex parameter of the quality of pulp milling and the complex parameter of the machine are obtained. Numerical value of complex parameter of grinding quality is determined depending on duration of grinding.

Downloads

Metrics

References

Baykov N.M., Grinkevich R.N. Prognoz razvitiya otrasley TEK v mire i po osnovnym regionam do 2030 g. [Forecast of the development of the fuel and energy complex industries in the world and by major regions until 2030]. Moscow, 2009, pp. 5. (in Russ.).

González I., Alcalà M., Chinga-Carrasco G. et al. Cellulose, 2014, vol. 21, pp. 2599–2609. DOI: 10.1007/s10570-014-0341-0.

Ivanov S.N. Tekhnologiya bumagi. [Paper technology]. Moscow, 2006, 696 p. (in Russ.).

Gu F., Wang W., Cai Z. et al. Cellulose, 2018, vol. 25, pp. 2861–2871. DOI: 10.1007/s10570-018-1765-8.

Krässig H.A. Cellulose: structure, accessibility and reactivity. Gordon and Breach, Yverdon. 1993. 376 p.

Hon D.N.A. Chemical modification of lignocellulosic materials. Marcel Dekker Inc. 1996. 384 p.

Pettersen R.C. The Chemistry of Solid Wood, 1984, vol. 207, pp. 57–126. DOI: 10.1021/ba-1984-0207.ch002.

Qu T., Guo W., Shen L., Xiao J., Zhao K. Industrial & Engineering Chemistry Research, 2011, vol. 50, no. 18, pp. 10424–10433. DOI: 10.1021/ie1025453.

Kamitakahara H., Koschella A., Mikawa Y., Nakatsubo F., Heinze T., Klemm D. Macromolecular bioscience, 2008, vol. 8, pp. 690-700. DOI: 10.1002/mabi.200700291.

Heinze T., Liebert T., Koschella A. Esterification of Polysaccharides. Berlin Heidelberg: Springer, 2006. 240 p.

Alashkevich YU.D. Osnovy teorii gidrodinamicheskoy obrabotki voloknistykh materialov v razmol'nykh mashinakh: dissertatsiya doktora tekhnicheskikh nauk. [Fundamentals of the theory of hydrodynamic processing of fibrous materials in grinding machines: dissertation of Doctor of Technical Sciences]. Leningrad, 1980, 334 p. (in Russ.).

Shurkina V.I., Marchenko R.A., Alashkevich Y.D. IOP Conference Series: Materials Science and Engineering, 2019, vol. 467, id. 012002. DOI: 10.1088/1757-899x/467/1/012002.

Kanavellis R. Teoreticheskiye osnovy inzhenernykh raschetov, 1968, vol. 90, no. 3, pp. 39–48. (in Russ.).

Goncharov V.N., Gauze A.A., Alikin V.P. Mashiny dlya rospuska i beznozhevogo razmola bumazhnoy massy. [Ma-chines for breaking up and knifeless grinding of paper pulp]. Leningrad, 1979, 106 p. (in Russ.).

Konturri E.J. Surface chemistry of cellulose: from natural fibres to model surfaces: Academic Dissertation Technische Universiteit Eindhoven, Niedereland. 2005. 145 p.

Sczostak A. Macromolecular Symposia, 2009, vol. 280, no. 1, pp. 45-53. DOI: https://doi.org/10.1002/masy.200950606.

Klemm D., Schumann D., Kramer F., Heßler N., Koth D., Sultanova B. Macromolecular Symposia, 2009, vol. 280, no. 1, pp. 60-71. DOI: https://doi.org/10.1002/masy.200950608.

Yerofeyeva A.A., Alashkevich YU.D., Baranovskiy V.P. Lesnoy vestnik, 2010, no. 4, pp. 157–160. (in Russ.).

Tavyrin N.P. Izvestiya AN SSSR. Otdeleniye tekhnicheskikh nauk, 1939, no. 7, pp. 25–44. (in Russ.).

Kuklin I.S., Kulikov G.S., Paducheva A.V. Trudy Instituta gornogo dela AN SSSR. Ural'skiy filial, 1962, issue 3, pp .87–90. (in Russ.).

Asatur K.G. Gidravlicheskiy raschet gidrootboyki gornykh porod // Izvestiya vuzov. Gornyy zhurnal, 1963, no. 7, pp. 23–28. (in Russ.).

Nurok G.A. Gidromekhanizatsiya otkrytykh gornykh razrabotok. [Hydromechanization of open pit mining]. Moscow, 1970, 584 p. (in Russ.).

Vasyutin V.G. Intensifikatsiya protsessa kombinirovannogo razmola tsellyuloznykh suspenziy: dissertatsiya kandidata tekhnicheskikh nauk. [Intensification of the process of combined grinding of cellulose suspensions: dissertation of the candidate of technical sciences]. Krasnoyarsk, 1987, 166 p. (in Russ.).

Vereshchagin L.F., Semerchan A.A., Filer F.M. Izvestiya AN SSSR. Otdeleniye tekhnicheskikh nauk, 1957, no. 1, pp. 57–60. (in Russ.).

Flyate D.M. Svoystva bumagi. [Properties of paper]. St. Petersburg, 2012, 384 p. (in Russ.).

Vasil'yeva D.YU., Yurtayeva L.V., Alashkevich YU. D. Otdel'nyye bumagoobrazuyushchiye svoystva volokna pri bez-nozhe-vom sposobe razmola // Problemy mekhaniki tsellyulozno-bumazhnykh materialov: materialy 5 mezhdunarodnoy nauchno-tekhnicheskoy konferentsii, posvyashchennoy pamyati professora V.I. Komarova. [Separate paper-forming properties of fiber in the knifeless grinding method in "Problems of the mechanics of pulp and paper materials: materials of the 5th international scientific and technical conference dedicated to the memory of Professor V.I. Komarov"], Arkhan-gelsk, 2019, pp. 81–87. (in Russ.).

Copyright (c) 2020 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.