INFLUENCE OF HYDROLYTIC TREATMENT ON THE CONTENT OF REDUCING SUBSTANCES IN NEUTRAL-SULPHITE ALKALI

UDC 663.15

Abstract

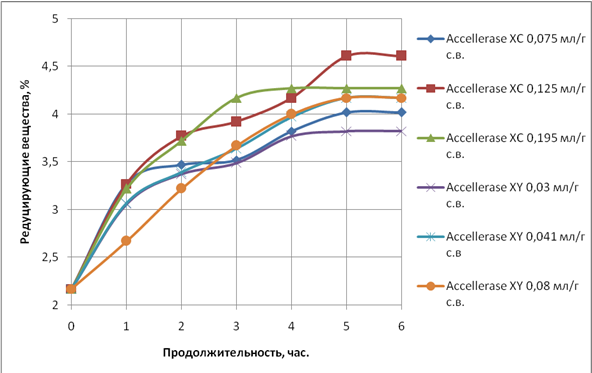

The aim of this work is to develop a technology for the preparation of neutral-sulfite liquors formed during the production of fibrous semi-finished products - cellulose from birch wood - for subsequent use as a nutrient medium for the cultivation of microorganisms. Acid hydrolysis was carried out at a temperature of 100 °С at a ratio of a 10% sulfuric acid solution to a liquor sample of 1 : 1. Enzymatic hydrolysis of neutral sulfite liquors was carried out with the enzyme preparations Accellerase XY and Accellerase XC at 50±2 °C and 60±2 °C. The end of hydrolysis was determined by the cessation of the increase in the content of reducing substances (RS) in the hydrolyzate. The original neutral sulphite lye contained 9.4% dry matter, 21.7 g/l of reducing substances, pH 5.3±0.2. It has been shown that as a result of enzymatic hydrolysis, the content of insoluble dry residue in the hydrolyzate decreases to 8.32% and 8.41%, respectively, and during acid hydrolysis – to 7.8%. The content of RS in neutral sulfite lye after acid hydrolysis increases by an average of 3 times, while after enzymatic hydrolysis - a maximum of 2 times.

It was found by gas-liquid chromatography that pentoses predominate in the obtained hydrolysates. Microbiological processing of media with a similar carbohydrate composition is possible by a number of strains of microorganisms capable of assimilating pentoses, for example, yeast-like fungi of the Saccharomycetaceae family and bacteria of the Enterobacteriaceae family.

Downloads

Metrics

References

Akim E.L. Khimicheskiye volokna, 2016, no. 3, pp. 4–13. (in Russ.).

Area M.C., Felissia F.E., Nunez C.E., Venica A., Valade J.L. Cellul. Chem. Technol., 2000, vol. 34, pp. 173–182.

Area M.C., Felissia F.E., Nunez C.E., Venica A., Valade J.L. Cellul. Chem. Technol., 2000, vol. 34, pp. 525–535.

Saeed A., Jahan M.S., Li H.M., Liu Z.H., Ni Y.H., van Heiningen A. Biomass Bioenergy, 2012, vol. 39, pp. 14–19. DOI: 10.1016/j.biombioe.2010.08.039.

Plaza G.A., Wandzich D. Management Systems in Production Engineering, 2016, no. 3, pp. 150–155. DOI: 10.2478/mspe-02-03-2016.

Carvalheiro F., Duarte L.C., Gírio F.M. Journal of Scientific & Industrial Research, 2008, vol. 67, pp. 849–864.

Schaidle J.A., Moline C.J., Savage P.E. Environmental Progress & Sustainable Energy, 2011, vol. 30, no. 4, pp. 743–753. DOI: 10.1002/ep.10516.

Hamelinck C.N., van Geertje H., Faaij A. Biomass and Bioenergy, 2005, vol. 28, pp. 384–410. DOI: 10.1016/j.biombioe.2004.09.002.

Wellisch M., Jungmeier G., Karbowski A., Patel M.K., Rogulska M. Biofuels, Bioprod, Biorefining, 2010, vol. 4, pp. 275–286. DOI: 10.1002/bbb.217.

Bozell J.J. CLEAN – Soil, Air, Water, 2008, vol. 36, pp. 641–647. DOI: 10.1002/clen.200800100.

Schieb P.-A., Philp J.C. Trends Biotechnol., 2014, vol. 32, pp. 496–500. DOI: 10.1016/j.tibtech.2014.08.006.

Stuart P. PulpPapCanada, 2006, vol. 107, pp. 13–16.

Bogolitsyn K.G., Reznikov V.M. Khimiya sul'fitnykh metodov delignifikatsii drevesiny. [Chemistry of sulfite methods of wood delignification]. Moscow, 1994, 288 p. (in Russ.).

Deshpande R., Sundvall L., Grundberg H., Germgard U. BioRes., 2016, vol. 11, pp. 5961–5973. DOI: 10.15376/biores.11.3.5961-5973.

Christoph L.P. Integrated Forest Biorefineries: Challenges and Opportunities. Cambridge, 2013, 313 p.

Cherubini F., Jungmeler G., Wellisch M., Willke T., Skiadas I., Van Ree R., de Jong E. Biofuels, Bioprod. Bioref., 2009, vol. 3, pp. 534–546. DOI: 10.1002/bbb.172.

Demirbas A. Biorefineries: For Biomass Upgrading Facilities. London, 2010, pp. 75–92.

Hamalainen S., Nayha A., Pesonen H.-L. J. Cleaner Prod., 2011, vol. 19, pp. 1884–1891. DOI: 10.1016/j.jclepro.2011.01.011.

GOST 2184-2013. Kislota sernaya tekhnicheskaya. [GOST 2184-2013. Technical sulfuric acid]. Moscow, 2014, 37 p. (in Russ.).

Morozova Yu.A., Skvortsov Ye.V., Alimova F.K., Kanarskiy A.V. Vestnik Kazanskogo tekhnologicheskogo universiteta, 2012, no. 19, pp. 120–122. (in Russ.).

Aleksandrova E.A., Gaydukova N.G. Analiticheskaya khimiya v 2 knigakh. Kniga 1. Khimicheskiye metody analiza. [Analytical chemistry in 2 books. Book 1. Chemical methods of analysis]. Moscow, 2018, 551 p. (in Russ.).

Mukhutdinov R.R., Pilipenko T.V., Kruchina-Bogdanov I.V. Vestnik YuUrGU. Seriya «Pishchevyye i biotekhnologii», 2019, no. 4, pp. 75–84. DOI: 10.14529/food190408. (in Russ.).

Chulkin A.M., Loginov D.S., Vavilova Ye.A., Abyanova A.R., Zorov I.N., Kurzeyev S.A., Koroleva O.V., Benevo-lenskiy S.V. Biokhimiya, 2009, no. 6, pp. 805–813. (in Russ.).

GOST R 55302-2012. Fermentnyye preparaty dlya pishchevoy promyshlennosti. Metod opredeleniya ksilanaznoy ak-tivnosti. [GOST R 55302-2012. Enzyme preparations for the food industry. Method for determination of xylanase ac-tivity]. Moscow, 2013, 12 p. (in Russ.).

Bolotnikova O.I., Mikhaylova N.P., Bazarnova Yu.G., Aronova Ye.B., Bolotnikova T.A., Akinina Yu.N. Izvestiya Vuzov. Prikladnaya khimiya i biotekhnologiya, 2019, no. 4, pp. 679–693. DOI: 10.21285/2227-2925-2019-9-4-679-693. (in Russ.).

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.