MODIFICATION OF AERODYNAMIC FORMING PAPER

UDC 676.168+676.026.723.8

Abstract

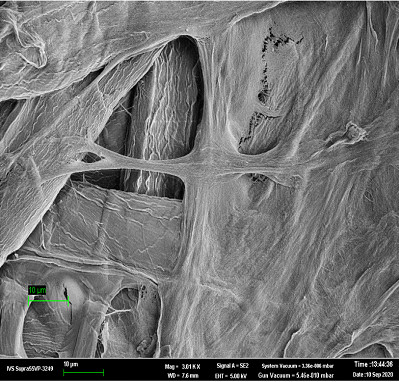

The use of natural nanocomponents for increasing the mechanical strength of paper in the aerodynamic method has been investigated. Milled bacterial cellulose and a fine fraction of sulphate bleached softwood cellulose formed during grinding (secondary fines) were used as nanocomponents. The treatment with nanocomponents was carried out while moistening the fibrous layer with the use of an anti-adhesive material providing uniform one sided application of substances in the form of a suspension on the paper surface. The growth of the indicators of the mechanical strength of paper occurred due to the formation of additional hydrogen bonds and an increase in the interfacial interaction between the fibrous layer of plant cellulose and the nanocomponent. It was found that the use of a suspension of bacterial cellulose is more promising due to the low consumption of the binder with a significant increase in the mechanical strength of the paper. The application of a bacterial cellulose coating layer on aerodynamically molded eucalyptus cellulose makes it possible to increase the mechanical strength of the paper to consumer requirements with the consumption of bacterial cellulose in an amount of 0.9% to 1.5% by weight of absolutely dry eucalyptus cellulose.

Downloads

Metrics

References

Patent 2100508 (RU). 27.12.1997. (in Russ.).

Kononov A., Paulapuro H., Drobosyuk V., Malinovskaya G., Terentiev O. Industiadella Carta, 2002, vol. 40 (8), pp. 37–48.

Drobosyuk V.M. Tekhnologiya bumagi aerodinamicheskim sposobom: nauchnoye izdaniye. [Paper technology in an aerodynamic way: scientific edition]. St. Petersburg, 2011, 56 p. (in Russ.).

Patent 2159304 (RU). 20.11.2000. (in Russ.).

Patent 2426828 (RU). 20.08.2011. (in Russ.).

Drobosyuk V.M., Malinovskaya G.K. Litvinova L.V. Izvestiya VUZov. Lesnoy zhurnal, 2015, no. 1, pp. 126–129. (in Russ.).

Litvinova L.V., Malinovskaya G.K. Vestnik SPbGUTD, 2018, no. 2, pp. 103–105. (in Russ.).

Malinovskaya G.K., Litvinova L.V. Khimiya rastitel'nogo syr'ya, 2019, no. 2, pp. 297–304. DOI: 10.14258/jcprm.2019023969. (in Russ.).

Midukov N.P., Yefremkina P.A., Malinovskaya G.K., Kurov V.S., Smolin A.S. Khimicheskiye volokna, 2017, no. 1, pp. 22–26. (in Russ.).

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva. T. 2. Proizvodstvo bumagi i kartona (Chast' 1). [Technology of pulp and paper production. Vol. 2. Manufacture of paper and cardboard (Part 1)]. St. Petersburg, 2005, 423 p. (in Russ.).

Klark Dzh. Tekhnologiya tsellyulozy (nauka o tsellyuloznoy masse i bumage, podgotovka massy, pererabotka yeye na bumagu, metody ispytaniy). [Pulp technology (pulp and paper science, pulp preparation, paper processing, test meth-ods)]. Moscow, 1983, 456 p. (in Russ.).

Dzhayme G., Khunger G. Osnovnyye predstavleniya o voloknakh, primenyayemykh v bumazhnom proizvodstve. Mate-rialy simpoziuma. [Basic ideas about fibers used in paper production. Symposium materials]. Moscow, 1962, 500 p. (in Russ.).

Malcolm R., Brown J.R. Pure Applied Chemistry, 1996, vol. 33, no. 10, pp. 1345–1373.

Zhijiang C., Jaehwan K. Cellulose, 2010, vol. 17, pp. 83–91.

Keshk S. J. Bioprocess Biotech., 2014, vol. 4, no. 2, 1000150.

Reznik A.S. Povysheniye termostabil'nosti komponentov vysokovol'tnoy bumazhno-propitannoy izolyatsii putem strukturnoy modifikatsii tsellyuloznoy bumagi: diss. … kand. tekhn. nauk. [Increasing the thermal stability of the com-ponents of high-voltage paper-impregnated insulation by structural modification of cellulose paper: diss. … cand. tech. Sciences]. St. Petersburg, 2017, 212 p. (in Russ.).

Patent 2415221 (RU). 27.03.2011. (in Russ.).

Gao W., Chen K., Yang R., Yang F., Han W. Bio Resources, 2011, vol. 6, pp. 144–153.

Basta A.N., El-Saied H. Journal of Applied Microbiology, 2009, vol. 107, pp. 2098–2107. DOI: 10.1111/j.1365-2672.2009.04467.

Yang J., Zhao C., Jiang Y., Han W. 4th International Conference on Machinery. Materialsand Computing Technolo-gy, 2016, pp. 391–394.

Materialy iz netraditsionnykh vidov volokon: tekhnologii polucheniya, svoystva, perspektivy primeneniya [Materials from non-traditional fiber types: production technologies, properties, application prospects], ed. A.V. Vurasko. Yekaterinburg, 2020, 252 p. (in Russ.).

Smirnova Ye.G. Povysheniye ustoychivosti bumagi k stareniyu formirovaniyem yeye kompozitsionnogo sostava: diss. … dokt. tekhn. nauk. [Increasing the resistance of paper to aging by the formation of its composition: diss. … doc. tech. Sciences]. St. Petersburg, 2014, 311 p. (in Russ.).

Völkel L., Ahn K., Hähner U., Gindl‑Altmutte W., Potthast A. Heritege Science, 2017, vol. 5, p. 23. DOI: 10.1186/s40494-017-0134-5.

Surma-Slusarska B., Presler S., Danielewicz D. FIBES & TEXILES in Eastern Europe, 2008, vol. 16, no. 4 (69), pp. 108–111.

Chawla P.R., Bajaj I.B., Survase S.A., Singhal R.S. Food Technology. Biotechnology, 2009, vol. 47, no. 2, pp. 107–124.

Smirnova Ye.G., Lotsmanova Ye.M. Vestnik SPbGUTD, 2019, no. 2, pp. 83–87. (in Russ.).

Drobosyuk V.M., Malinovskaya G.K. Dispergirovaniye tsellyuloznykh materialov v protsesse aerodinamichesko-go formovaniya bumagi. Nauchnoye izdaniye. [Dispersion of cellulose materials in the process of aerodynamic formation of paper. Scientific publication]. St. Petersburg, 2015, 72 p. (in Russ.).

Copyright (c) 2022 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.