FUNCTIONAL MATERIALS FROM WASTE PAPER. III. COMPARATIVE STUDY OF MORPHOLOGY OF POWDER CELLULOSES AND CELLULOSE HYDROGELS

UDC 676.038.22/677.014.84

Abstract

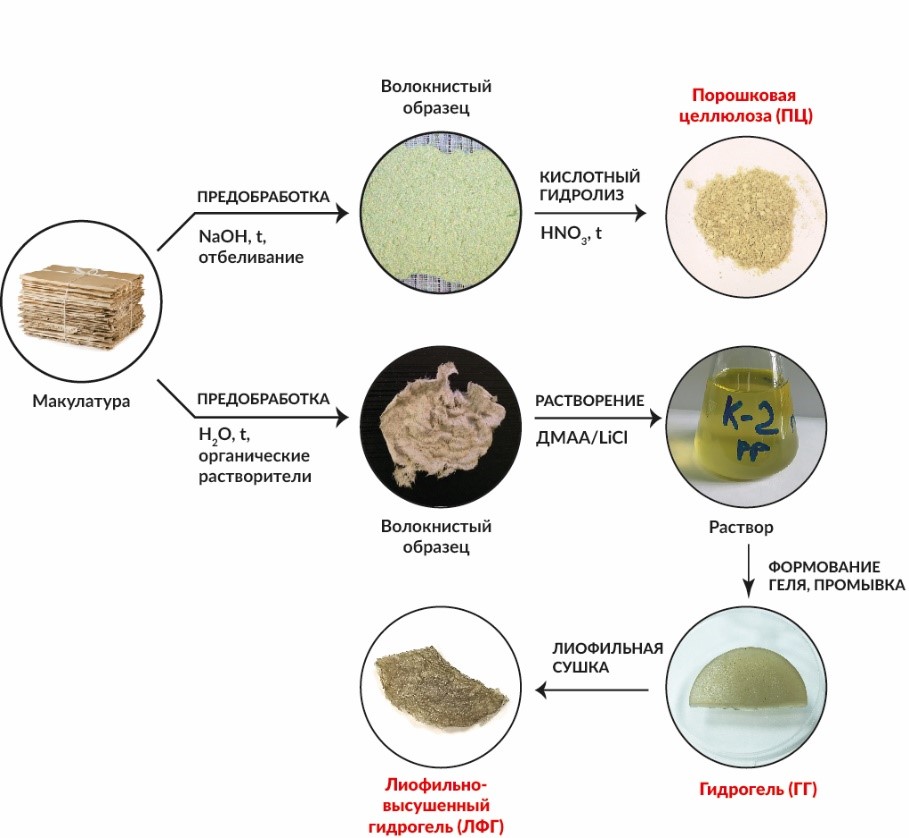

The morphology of hydrogels regenerated from solutions of waste paper and cardboard in DMAс/LiCl was studied for the first time in comparison with the morphology of pristine samples and powder celluloses isolated from waste paper. Two sets consisted every of them from 4 samples, pristine waste paper or cardboard, powder cellulose, swollen hydrogel and freeze-dried hydrogel, were examined with a SEM. As revealed by SEM, the freeze-dried hydrogels are porous systems with a variety of through pores in a wide range of sizes. The number, shape, and size of pores, as well as their availability, differed markedly. The pore sizes in freeze-dried hydrogels obtained from the waste paper are mostly ranged at 30-50 nm. The smallest pores in the waste cardboard are 30-40 nm in size, the largest ones are up to 4 μm. According to the results of the study, these samples will have satisfactory sorption properties but, due to the different morphology of the porous system, the availability of each sample is likely to vary significantly.

Downloads

Metrics

References

Obrazovaniye, utilizatsiya, obezvrezhivaniye i razmeshcheniye otkhodov proizvodstva i potrebleniya v Rossiyskoy Fed-eratsii // Federal'naya sluzhba gosudarstvennoy statistiki [Education, utilization, neutralization and disposal of produc-tion and consumption waste in the Russian Federation // Federal State Statistics Service], 2020. URL: https://rosstat.gov.ru/folder/11194#. (in Russ.).

Volkova A.V. Rynok utilizatsii otkhodov. Doklad NIU VSHE. [Waste disposal market. HSE report]. Moscow, 2018, 87 p. (in Russ.).

Makulaturnyy potentsial: chto sderzhivayet pererabotku vtorsyr'ya [Waste paper potential: what is holding back recy-cling]. URL: https://plus.rbc.ru/partners/5f449d1a7a8aa9cbc38234d9. (in Russ.).

GOST 10700-97. Makulatura bumazhnaya i kartonnaya. Tekhnicheskiye usloviya. [GOST 10700-97. Waste paper and cardboard. Technical conditions]. Moscow, 2003, 13 p. (in Russ.).

Ünlü C.H. Carbohydr. Polym., 2013, vol. 97, no. 1, pp. 159‒164. DOI: 10.1016/j.carbpol.2013.04.039.

Guo X., Jiang Zh., Li H., Li W. J. Appl. Polym. Sci., 2015, vol. 132(19), 41962. DOI: 10.1002/app.41962.

Hospodarova V., Stevulova N., Briancin J., Kostelanska K. Buildings, 2018, vol. 8, pp.1‒12. DOI: 10.3390/buildings8030043.

Pang S.C., Chin S.F., Yih V. Adv. Mater. Lett., 2011, vol. 2, no. 2, pp. 118‒124. DOI: 10.5185/amlett.2011.1203.

Kumar V., Pathak P., Bhardwaj N.K. J. Waste Manag., 2020, vol. 102, pp. 281‒303. DOI: 10.1016/j.wasman.2019.10.041.

Tang Y., Shen X., Zhang J., Guo D., Kong F., Zhang N. Carbohyd. Polym., 2015, vol. 125, pp. 360‒366. DOI: 10.1016/j.carbpol.2015.02.063.

Feng J.D., Nguyen S.T., Duong H.M. Adv. Mater. Res., 2014, vol. 936, pp. 938‒941. DOI: 10.4028/www.scientific.net/amr.936.938.

Zhen L.W., Thai Q.B., Nguyen Th.X., Le D.K., Lee J.K.W. et al. Fluids, 2019, vol. 4(3), 174. DOI: 10.3390/fluids4030174.

Jin C., Han S., Li J., Sun Q. Carbohydr. Polym., 2015, vol. 123, no. 5, pp. 150‒156. DOI: 10.1016/j.carbpol.2015.01.056.

Fan P., Yuan Y., Ren J., Yuan B., He Q. et al. Carbohydr. Polym., 2017, vol. 162, pp. 108‒114. DOI: 10.1016/j.carbpol.2017.01.015.

Feng J.D., Nguyen S.T., Fan Z., Duong H.M. Chem. Eng. J., 2015, vol. 270, pp. 168‒175. DOI: 10.1016/j.cej.2015.02.034.

Fridrihsone V., Zoldners J., Skute M., Grinfelds U., Filipova I., Sivacovs I., Spade M., Laka M. Key Eng. Mater., 2019, vol. 800, pp. 138‒144. DOI: 10.4028/www.scientific.net/kem.800.138.

Zhang Sh., Zhang F., Jin L., Liu B., Mao Y., Ya L.J. Cellulose, 2019, vol. 26, pp. 5177–5185. DOI: 10.1007/s10570-019-02434-9.

Mikhailidi A.M., Kotelnikova N.E. Buletinul Institutului Politehnic din Iasi. Sectia Chemie si inginerie chimica, 2021, vol. 67(71), no. 1, pp. 35–42.

Mikhailidi A.M., Saurov Sh.K., Markin V.I., Kotel'nikova N.Ye. Khimiya rastitel'nogo syr'ya, 2018, no. 2, pp. 27–35. DOI: 10.14258/JCPRM.2018023693. (in Russ.).

Kotel'nikova N.Ye., Mikhailidi A.M., Martakova Yu.V. Vysokomolekulyarnyye soyedineniya. Seriya A, 2017, vol. 59, no. 1, pp. 76–87. DOI: 10.1134/S0965545X17010084. (in Russ.).

Kotelnikova N.E., Mikhailidi A.M., Martakova Yu.V., Andersson S. Cellul. Chem. Technol., 2016, vol. 50, no. 3–4, pp. 545–555.

Kotelnikova N.E., Stoll M., Wegener G., Windeisen E., Wenzkowski M., Demidov V., Aleksandrova E. Cellul. Chem. Technol., 2002, vol. 37, no. 1, pp. 51‒67.

Ohwoavworhua F.O., Adelakun T.A. Trop. J. Pharm. Res., 2005, vol. 4, no. 2, pp. 501‒507. DOI: 10.4314/tjpr.v4i2.14626.

Rojas J. Effect of Polymorphism on the Particle and Compaction Properties of Microcrystalline Cellulose. In: Cellu-lose – Medical, Pharmaceutical and Electronic Applications, ed. T. van de Ven, L. Godbout. IntechOpen. DOI: 10.5772/56591.

Nwachukwui N., Ofoefule S.I. Braz. J. Pharm. Sci., 2020, vol. 56, pp. 1‒17. DOI: 10.1590/s2175-97902020000118060.

Beaumont M., Buchegger B., Plappert S.F., Nedelec J.-M., Opietnik M., Potthast A., Rosenau Th. Cellulose, 2019, vol. 26, pp. 683‒686. DOI: 10.1007/s10570-018-2147-y.

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.