OBTAINING LOW-MOLECULAR WEIGHT GALACTOMANNANES AND STUDYING THEIR PHYSICO-CHEMICAL CHARACTERISTICS

UDC 541.6.69.615.01

Abstract

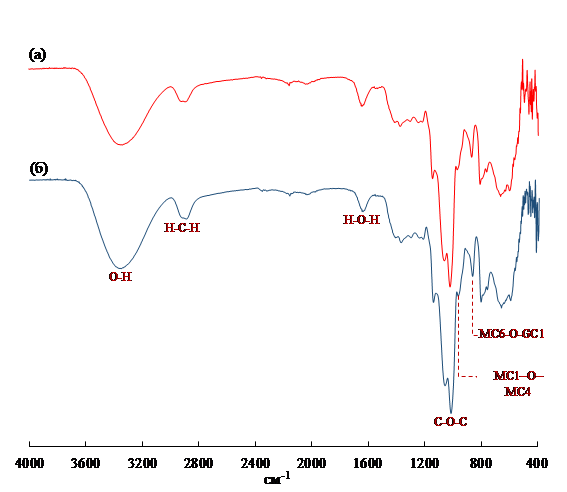

The aim of this study was studying the effect of acidic hydrolysis conditions on the molecular parameters of galactomannan, such as weight average degree of polymerization (DPw), weight average molecular weight (Mw), product yield, depolymerization reaction rate, and mannose/galactose (Man/Gal) ratio in the presence of hydrochloric acid and obtaining low molecular weight oligogalactomannans soluble in water. A preparing possibility low molecular weight galactomannans by acid hydrolysis of guar galactomannan (DPw=1160, Mw=563.8 kDa, Man/Gal=1.89) in the presence of hydrochloric acid was studied. The studies were carried out in hydrochloric acid solutions with various concentrations (0.05–1.0 mol/L) for different times (10–240 min) at a constant temperature (80 °C). In the course of the studies, effects of the reaction conditions on the molecular parameters of the product obtained were analyzed. The conducted reactions yielded low molecular weight galactomannans and oligogalactomannans with different molecular parameters (DPw=6–1021, Mw=2.6–505.1 kDa, Man/Gal=1.90–3.19) and yields (2.8–97.1%). Based on the results obtained, the optimal reaction conditions (HCl 0.1 mol/L, 240 min, 80 °C) were supposed for the preparation of galactomannan oligosaccharides. The structural studies of the products indicated that products with reduced galactose residues could be prepared by this method.

Downloads

Metrics

References

Pawar H.A. Biol. Med., 2015, vol. 7, 224. DOI: 10.4172/0974-8369.1000224.

Aravamudhan A., Ramos D.M., Nada A.A., Kumbar S.G. Nat. Synth. Biomed. Polym. Elsevier Inc., 2014, pp. 67–89. DOI: 10.1016/B978-0-12-396983-5.00004-1.

Prajapati V.D., Jani G.K., Moradiya N.G., Randeria N.P., Nagar B.J., Naikwadi N.N. et al. Int. J. Biol. Macromol., 2013, vol. 60, pp. 83–92. DOI: 10.1016/J.IJBIOMAC.2013.05.017.

Whistler R.L., BeMiller J.N. Industrial Gums: Polysaccharides and Their Derivatives. Academic Press, 2012. DOI: 10.1016/C2009-0-03188-2.

Borsig L. Glycobiology, 2018, vol. 28, pp. 648–655. DOI: 10.1093/glycob/cwx105.

Banerjee S., Parasramka M., Paruthy S.B. Polysaccharides. Springer, Cham, 2015, pp. 2179–2214. DOI: 10.1007/978-3-319-16298-0_26.

Zhang X., Qi C., Guo Y., Zhou W., Zhang Y. Carbohydr. Polym., 2016, vol. 149, pp. 186–206. DOI: 10.1016/j.carbpol.2016.04.097.

Cerqueira M.A., Bourbon A.I., Pinheiro A.C., Martins J.T., Souza B.W.S., Teixeira J.A. et al. Trends Food Sci. Technol., 2011, vol. 22, pp. 662–671. DOI: 10.1016/J.TIFS.2011.07.002.

Gaisford S.E., Harding S.E., Mitchellt J.R., Bradley T.D., Mitchell J.R. Carbohydr. Polym., 1986, vol. 6, pp. 423–442.

Pitkänen L., Tuomainen P., Mikkonen K.S., Tenkanen M. Carbohydr. Polym., 2011, vol. 86, pp. 1230–1235. DOI: 10.1016/j.carbpol.2011.06.018.

Rakhmanberdyeva R.K., Rakhimov D.A., Vakhabov A.A., Khushbaktova Z.A., Syrov V.N. Chem. Nat. Compd., 2005, vol. 41, pp. 11–13. DOI: 10.1007/s10600-005-0062-6.

Rashid F., Hussain S., Ahmed Z. Carbohydr. Polym., 2018, vol. 180, pp. 88–95. DOI: 10.1016/j.carbpol.2017.10.025.

Azimova L.B., Normakhamatov N.S., Khaytmetova S.B., Mukhitdinov B.I., Amonova D.M., Filatova A.V. et al. Russ. J. Bioorganic Chem., 2020, vol. 46, pp. 1317–1322. DOI: 10.1134/S106816202007002X.

Cheng Y., Prud’homme R.K. Biomacromolecules, 2000, vol. 1, pp. 782–788. DOI: 10.1021/bm005616v.

Sun M., Tang H.B., Dong S.Q., Li Y.P. Adv. Mater. Res., 2013, vol. 781–784, pp. 1901–1906. DOI: 10.4028/www.scientific.net/AMR.781-784.1901.

Wang Q., Ellis P., Ross-Murphy S. Food Hydrocoll., 2000, vol. 14, pp. 129–134. DOI: 10.1016/S0268-005X(99)00058-2.

Horinaka J., Yasuda R., Takigawa T. Carbohydr. Polym., 2012, vol. 89, pp. 1018–1021. DOI: 10.1016/j.carbpol.2012.03.038.

Muhitdinov B., Heinze T., Turaev A., Koschella A., Normakhamatov N. Eur. Polym. J., 2019, vol. 119, pp. 181–188. DOI: 10.1016/j.eurpolymj.2019.07.030.

Wielinga W.C. Handb. Hydrocoll., 2nd ed. Woodhead Publishing, 2009, pp. 228–251. DOI: 10.1533/9781845695873.228.

Lacroix C., Sultan E., Fleury E., Charlot A. Polym. Chem., 2012, vol. 3, pp. 538–546. DOI: 10.1039/C2PY00512C.

Cunha P.L.R., Vieira Í.G.P., Arriaga Â.M.C., de Paula R.C.M., Feitosa J.P.A. Food Hydrocoll., 2009, vol. 23, pp. 880–885. DOI: 10.1016/j.foodhyd.2008.05.005.

Muhitdinov B., Heinze T., Normakhamatov N., Turaev A. Carbohydr. Polym., 2017, vol. 173, pp. 631–637. DOI: 10.1016/j.carbpol.2017.06.033.

Jiang J.-X., Jian H.-L., Cristhian C., Zhang W.-M., Sun R.-C. J. Sci. Food Agric., 2011, vol. 91, pp. 732–737. DOI: 10.1002/jsfa.4243.

Chaubey M., Kapoor V.P. Carbohydr. Res., 2001, vol. 332, pp. 439–444. DOI: 10.1016/S0008-6215(01)00104-5.

Davis A.L., Hoffmann R.A., Russell A.L., Debet M. Carbohydr. Res., 1995, vol. 271, pp. 43–54. DOI: 10.1016/0008-6215(95)00038-U.

Copyright (c) 2022 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.