DEVELOPMENT TECHNOLOGY OF SULFITE PULP TCF BLEACHING FOR CHEMICAL PROCESSING

UDC 676.163.023.1

Abstract

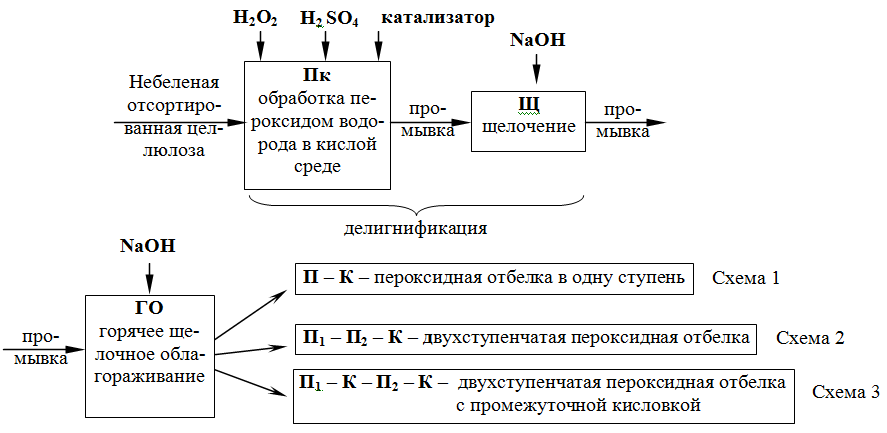

An environmentally friendly chlorine-free technology for producing wood sulfite soluble pulp using only one oxidizing bleaching agent – hydrogen peroxide has been developed: unconventional catalyzed peroxide delignification and hydrogen peroxide bleaching. The conditions of cooking, delignification, extraction and bleaching of spruce sulfite pulp obtained as a result of studies, as well as successful combinations of conditions of all stages made it possible to obtain two types of soluble pulp by one technology: soluble pulp for nitration (for gunpowder) was obtained under a short scheme including a delignification step and hot alkaline extraction; by continuing this scheme with hydrogen peroxide bleaching in two steps, viscose pulp was obtained. The use of this technology will make it possible to implement a double import substitution – in raw materials (wood instead of cotton) and in finished products (pulp for chemical processing - for nitration and viscose pulp, which are currently imported).

Downloads

Metrics

References

Kosaya G.S. Proizvodstvo sul'fatnoy viskoznoy tsellyulozy. [Production of sulfate viscose pulp]. Moscow, 1966, 181 p. (in Russ.).

Novozhilov Ye.V., Novozhilov Ye.V., Poshina D.N. Khimiya rastitel'nogo syr'ya, 2011, no. 3, pp. 15–32. (in Russ.).

Yakusheva A.A. Sbornik materialov VI Vserossiy-skoy nauchno-prakticheskoy konferentsii studentov, aspirantov i molodykh uchenykh s mezhdunarodnym uchastiyem «Tekhnologii i oborudovaniye khimicheskoy, biotekhnologicheskoy i pishchevoy promyshlennosti». [Collection of materials of the VI All-Russian scientific-practical conference of stu-dents, graduate students and young scientists with international participation "Technologies and equipment of the chem-ical, biotechnological and food industry"]. Biysk, 2013, pp. 139–141. (in Russ.).

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva. Spravochnyye materialy. V 3-kh t. T. III. Avtomatizatsiya, standartizatsiya, ekonomika i okhrana okruzhayushchey sredy. Ch. 3. Nailuchshiye dostupnyye tekhnologii v tsellyu-lozno-bumazhnoy promyshlennosti. [Technology of pulp and paper production. Reference materials. In 3 volumes. Vol. III. Automation, standardization, economics and environmental protection. Part 3. Best available technologies in the pulp and paper industry]. St. Petersburg, 2012, 294 p. (in Russ.).

Shumnyy V.K., Kolchanov N.A., Sakovich G.V., Parmon V.N., Veprev S.G., Nechiporenko N.N., Goryachkov-skaya T.N., Bryanskaya A.V., Budayeva V.V., Zheleznov A.V., Zheleznova N.B., Zolotukhin V.N., Mitrofanov R.Yu., Rozanov A.S., Sorokina K.N., Slyn'ko N.M., Yakovlev V.A., Pel'tek S.Ye. Informatsionnyy vestnik VOGiS, 2010, vol. 14, no. 3, pp. 569–577. (in Russ.).

Nepenin N.N., Nepenin Yu.N. Tekhnologiya tsellyulozy. T. 3. Ochistka, sushka i otbelka tsellyulozy. Prochiye sposoby polucheniya tsellyulozy: Uchebnoye posobiye dlya vuzov. [Pulp Technology. Vol. 3. Cleaning, drying and bleaching of pulp. Other methods of obtaining cellulose: Textbook for universities]. Moscow, 1994, 592 p. (in Russ.).

Akim G.L. Tsellyuloza. Bumaga. Karton, 2001, no. 5-6, pp. 24–28. (in Russ.).

Sergeyev A.D., At'man O.P., Sergeyeva I.V. Tsellyuloza. Bumaga. Karton, 2008, no. 2, pp. 58–62. (in Russ.).

Shpakov F.V., Nevolin V.F. Nauchno-tekhnicheskaya konferentsiya RAR-FOR 98. [Scientific and technical conference PAP-FOR 98]. St. Petersburg, 1998, pp. 74–79. (in Russ.).

Fedorova E.I., Kuzivanova A.V. Tsellyuloza. Bumaga. Karton, 2007, no. 5, pp. 52–54. (in Russ.).

Polyutov A.A., Pen R.Z., Byvshev A.V. Tekhnologiya tsellyulozy. Ekologicheski chistoye proizvodstvo: ucheb. po-sobiye. [Cellulose technology. Environmentally friendly production: textbook. allowance]. Krasnoyarsk, 2012, 294 p. (in Russ.).

Khakimova F.Kh., Sinyayev K.A. Khimiya rastitel'nogo syr'ya, 2013, no. 2, pp. 57–62. (in Russ.).

Khakimova F.Kh., Nagimov D.R., Khakimov R.R., Noskova O.A. Zhurnal prikladnoy khimii, 2013, vol. 86, no. 10, pp. 1565–1570. (in Russ.).

Pen R.Z. Tekhnologiya tsellyulozy. T. 2. Sul'fitnyye sposoby polucheniya, ochistka, otbelka, sushka tsellyulozy: uchebnoye posobiye dlya vuzov. [Cellulose technology. Vol. 2. Sulfite methods for obtaining, cleaning, bleaching, dry-ing of cellulose: a textbook for universities]. Krasnoyarsk, 2002, 358 p. (in Russ.).

Khakimova F.Kh., Noskova O.A., Kotel'nikov S.A., Sinyayev K.A. Vestnik Permskogo natsional'nogo politekhniche-skogo universiteta. Aerokosmicheskaya tekhnika, 2019, no. 1(56), pp. 72–82. (in Russ.).

Khakimova F.Kh., Sinyayev K.A. Khimiya rastitel'nogo syr'ya, 2019, no. 1, pp. 287–294. (in Russ.).

Pen R.Z., Pen V.R. Teoreticheskiye osnovy delignifikatsii. [Theoretical foundations of delignification]. Krasnoyarsk, 2007, 348 p. (in Russ.).

Demin V.A. Khimiya drevesiny, 1994, no. 3, pp. 29–37. (in Russ.).

Paren A., Yaakara Y. Tsellyuloza. Bumaga. Karton, 1999, no. 1-2, pp. 20–23. (in Russ.).

Zhegrov F.Kh., Milekhin Yu.M., Berkovskaya Ye.V. Khimiya i tekhnologiya ballistitnykh porokhov, tverdykh raket-nykh i spetsial'nykh topliv. T. 2. Tekhnologiya: Monografiya. [Chemistry and technology of ballistic powders, solid rocket and special propellants. Vol. 2. Technology: Monograph]. Moscow, 2011, 551 p. (in Russ.).

Copyright (c) 2022 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.