APPLICATION OF CHITOSAN-BASED PRODUCTS TO INCREASE HYDROPHOBIC PROPERTIES OF CRAFT PA-PER

UDC 676.017.66

Abstract

We devoted our research to study and substantiate the possibility of using products based on commercial chitosan. As an animal polysaccharide, it was applied as an additive in manufacturing laboratory samples of kraft packaging paper with increased hydrophobic properties.

The research aimed to optimize conditions to produce packaging kraft paper by means of mathematical planning method of the experiment in accordance with the three factor uniform-rotatable second-order model by Box and Hunter.

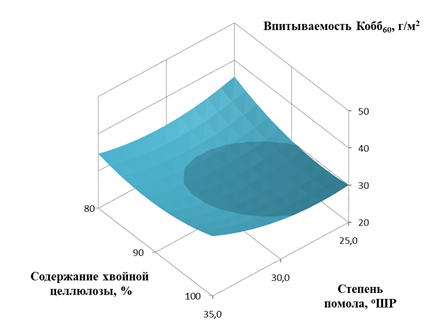

It is shown that that the effective hydrophobization of a fairly thin cellulose fibrous material, weight of 1 m2 70 g, is possible. In the studied factor space, we have established mathematical dependences that fit well the influence of the main technological parameters – the consumption of chitosan (0.5–1.5%), the beating degree of paper pulp (25–35 °SR) and softwood content in fiber furnish (80–100%) on the hydrophobicity (increasing moisture resistance) of paper and its physical and mechanical properties.

It is shown that the presence of chitosan in fiber furnish leads to the hydrophobicity of kraft paper in terms of surface water absorption during one-sided wetting (Cobb test) increases many times and reaches 24–25 g/m2 at the maximum product consumption (1.5%). At the same time, the values of beating degree of paper pulp and softwood content in fiber furnish can vary in a fairly wide technological range, in accordance with the studied factor spaces.

Increasing the consumption of chitosan, the beating degree of pulp fibers and softwood content in fiber furnish simultaneously provides an increase in the values of almost all physical and mechanical properties of laboratory kraft packaging paper.

Downloads

Metrics

References

Khitozan. [Chitosan], ed. K.G. Skryabin, S.N. Mikhaylov, V.P. Varlamov. Moscow, 2013, 593 p. (in Russ.).

Khitin i khitozan: polucheniye, svoystva i primeneniye. [Chitin and chitosan: obtaining, properties and application], ed. K.G. Skryabin, G.A. Vikhoreva, V.P. Varlamov. Moscow, 2002, 368 p. (in Russ.).

Nemtsev S.V. Kompleksnaya tekhnologiya khitina i khitozana iz pantsirya rakoobraznykh. [Integrated technology of chitin and chitosan from crustacean shell]. Moscow, 2006, 134 p. (in Russ.).

Bykova V.M., Nemtsev S.V. Khimiya i tekhnologiya polimerov. [Chemistry and technology of polymers]. Moscow, 2002, vol. 1, pp. 6–22. (in Russ.).

Fedoseyeva Ye.N., Alekseyeva M.F., Smirnova L.A. Vestnik Nizhegorodskogo universiteta im. N.I. Lobachevskogo, 2008, no. 5, pp. 58–62. (in Russ.).

Brovko O.S., Kazakov Ya.V., Boytsova T.A., Palamarchuk I.A. Problemy mekha-niki tsellyulozno-bumazhnykh mate-rialov: materialy I Mezhdunarodnoy nauchno-tekhnicheskoy konferentsii, posvyashchennoy pamyati professora V.I. Komarova. [Problems of the mechanics of pulp and paper materials: materials of the I International Scientific and Technical Conference dedicated to the memory of Professor V.I. Komarova]. Arkhangelsk, 2011, pp. 251–256. (in Russ.).

Brovko O.S., Kazakov Ya.V., Boytsova T.A., Palamarchuk I.A., Tormosina D.A., Bogolitsin K.G. Problemy mekha-niki tsellyulozno-bumazhnykh materialov: materialy II Mezhdunarodnoy nauchno-tekhnicheskoy konferentsii, posvyashchennoy pamyati professora V.I. Komarova. [Problems of the mechanics of pulp and paper materials: materi-als of the II International Scientific and Technical Conference dedicated to the memory of Professor V.I. Komarova]. Arkhangelsk, 2013, pp. 176–181. (in Russ.).

Ageyev Ye.P., Vikhoreva G.A., Matushkina N.N. et al. Vysokomolekulyarnyye soyedineniya A, 2000, vol. 42, no. 2, pp. 333–339. (in Russ.).

Chernyshova Ye.B. Modifikatsiya plenochnykh materialov na osnove khitozana nizkomolekulyarnymi i polimernymi al'degidami: dis. … kand. khim. nauk. [Modification of film materials based on chitosan with low molecular weight and polymeric aldehydes: diss. … cand. chem. Sciences]. Volgograd, 2018, 116 p. (in Russ.).

Patent 2293751 (RU). 2007. (in Russ.).

Patent 2667450 (RU). 2018. (in Russ.).

Patent 112647357 (CN). 2021.

Patent 112609509 (CN). 2021.

Patent 108797195 (CN). 2018.

Patent 106801362 (CN). 2017.

Patent 2003166197 (JP). 2013.

Patent H08218294 (JP). 1996.

Patent 2025890 (NL). 2021.

GOST 14363.4-89. Tsellyuloza. Metod podgotovki prob k fiziko-mekhanicheskim ispytaniyam. [GOST 14363.4-89. Cellulose. Method for preparing samples for physical and mechanical tests]. Moscow, 1989, 14 p. (in Russ.).

GOST 13523-78. Polufabrikaty voloknistyye, bumaga i karton. Metod konditsionirovaniya obraztsov (s Izmeneniyami N 1, 2, 3). [GOST 13523-78. Semi-finished fibrous products, paper and cardboard. Sample Conditioning Method (with Amendments no. 1, 2, 3)]. Moscow, 1999, 4 p. (in Russ.).

GOST 27015-86. Bumaga i karton. Metody opredeleniya tolshchiny, plotnosti i udel'nogo ob"yema. [GOST 27015-86. Paper and cardboard. Methods for determining thickness, density and specific volume]. Moscow, 2002, 4 p. (in Russ.).

GOST 13525.1-79. Polufabrikaty voloknistyye, bumaga i karton. Metody opredeleniya prochnosti na razryv i udlineni-ya pri rastyazhenii (s Izmeneniyami N 1, 2). [GOST 13525.1-79. Semi-finished fibrous products, paper and cardboard. Methods for determining tensile strength and tensile elongation (with Amendments no. 1, 2)]. Moscow, 2007, 5 p. (in Russ.).

GOST 12605-97 (ISO 535-91). Bumaga i karton. Metod opredeleniya poverkhnostnoy vpityvayemosti vody pri odnos-toronnem smachivanii (metod Kobba). [GOST 12605-97 (ISO 535-91). Paper and cardboard. Method for determining the surface water absorption with one-sided wetting (Cobb method)]. Minsk, 2001, 8 p. (in Russ.).

GOST 13525.8-86. Polufabrikaty voloknistyye, bumaga i karton. Bumaga i karton. Metod opredeleniya soprotivleniya prodavlivaniyu. [GOST 13525.8-86. Semi-finished fibrous products, paper and cardboard. Paper and cardboard. Method for determining bursting resistance]. Moscow, 2007, 6 p. (in Russ.).

Bogdanovich N.I., Kuznetsova L.N., Tret'yakov S.I., Zhabin V.I. Raschety v planirovanii eksperimenta: uchebnoye posobiye. [Calculations in experiment planning: a tutorial]. Arkhangelsk, 2008, 124 p. (in Russ.).

Pen R.Z. Planirovaniye eksperimenta v Statgraphics. [Planning an experiment in Statgraphics]. Krasnoyarsk, 2003, 246 p. (in Russ.).

Copyright (c) 2023 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.