PROPERTIES OF GLUED PAPER FROM CELLULOSE MASS OF MULBERRY TREE BRANCHES

UDC 676.014

Abstract

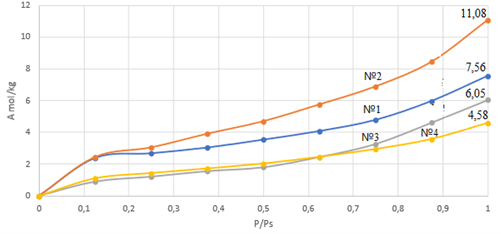

In an article to study the effect of sizing agent and filler on the structural features of paper from the cellulose mass of the inner layer of the bark of mulberry tree branches, mechanical strength, absorbency and sorption properties were studied. Tensile strength was determined on a tensile testing machine by the force causing the destruction of the sample. Surface absorbency at one side wetting was determined by the method of Cobb(30), by determining the mass of water absorbed by the surface of the paper when wetting one side of the test sample. Sorption properties were studied on a high-vacuum setup with mercury gates and McBain quartz balances according to water vapor sorption data. It was found that the internal 2% sizing of the paper pulp with cherry tree resin glue contributes to the strengthening of the paper structure, which is confirmed by the values of mechanical strength and surface absorbency when unilaterally wetted with water, relative to the values obtained when sizing with pine oleoresin rosin glue. When using glue from cherry resin, it is advisable to add 2 g of kaolin to 100 g of pulp from the inner layer of the bark of mulberry tree branches, since the increase negatively affects mechanical strength and hydrophobicity.

Downloads

Metrics

References

Kermanyan Kh. Novyy kompozitsionnyy kley dlya prokleyki tsellyuloznykh materialov: diss. … kand. tekhn. nauk. [New composite adhesive for sizing cellulose materials: diss. … cand. tech. sciences]. Moscow, 2001, 22 p. (in Russ.).

Yeshbayeva U.Zh., Ismailova G.I., Nishonov A.M., Abdualimova L.Z. Universum: tekhnicheskiye nauki: elektronnyy nauchnyy zhurnal, 2021, no. 7 (88). (in Russ.).

Makhotina L.G. Tsellyuloza. Bumaga. Karton, 2008, no. 3, pp. 52–55. (in Russ.).

Kuleshov A.V., Smolin A.S. Khimiya Rastitel’nogo Syr’ya, 2008, no. 2, pp. 109–112. (in Russ.).

Babakhanova Kh.A. Pechatno-tekhnicheskiye svoystva bumag s komponentami volokon shelka i kenafa: diss. … kand. tekhn. nauk. [Printing and technical properties of papers with components of silk and kenaf fibers: diss. … cand. tech. sciences]. Tashkent, 2000, 132 p. (in Russ.).

Tarasov S.M., Koverninskiy I.N. Nauchnyye trudy. [Scientific works]. Moscow, 2002, vol. 319, pp. 83–88. (in Russ.).

Tarasov S.M., Koverninskiy I.N., Azarov V.I. Lesnoy vestnik, 2003, no. 5, pp. 89–92. (in Russ.).

Mullina E.R., Mishurina O.A., Chuprova L.V., Yershova O.V. Sovremennyye problemy nauki i obrazovaniya, 2014, no. 6. URL: https://science-education.ru/ru/article/view?id=16572. (in Russ.).

Babakhanova Kh.A., Galimova Z.K., Abdunazarov M.M., Ismailov I.I. Khimiya Rastitel’nogo Syr’ya, 2020, no. 4, pp. 261–266. DOI: 10.14258/jcrm.2020047761. (in Russ.).

Babakhanova Kh.A., Galimova Z.K., Abdunazarov M.M., Ismailov I.I. Lesnoy zhurnal, 2020, no. 5, pp. 193–200. DOI: 10.37482/0536-1036-2020-5-193-200. (in Russ.).

Mishurina O.A., Tagayeva K.A. Aktual'nyye problemy sovremennoy nauki, tekhniki i obrazovaniya, 2013, vol. 1, no. 71, pp. 286–289. (in Russ.).

Mishurina O.A., Yershova O.V., Chuprova L.V., Mullina E.R. Fundamental'nyye issledovaniya, 2015, no. 2–19, pp. 4166–4170. (in Russ.).

Mishurina O.A., Zheryakova K.V., Mullina E.R. Mezhdunarodnyy zhurnal prikladnykh i fundamental'nykh issledo-vaniy, 2015, no. 6–1, pp. 83–85. (in Russ.).

Mishurina O.A., Mullina E.R., Zheryakova K.V., Korniyenko N.D., Fodorova Yu.S. Mezhdunarodnyy zhurnal prikladnykh i fundamental'nykh issledovaniy, 2015, no. 6–2, pp. 200–202. (in Russ.).

Flyate D.M. Tekhnologiya bumagi: ucheb. dlya vuzov. [Paper technology: textbook. for universities]. Moscow, 1988, 440 p. (in Russ.).

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva. Spravochnyye materialy. T. I.: Syr'ye i proizvodstvo polufabri-katov. [Technology of pulp and paper production. Reference materials. Vol. I.: Raw materials and production of semi-finished products]. St. Petersburg, 2002, 419 p. (in Russ.).

Kurkova Ye.V., Ivanov G.Ye. Problemy mekhaniki tsellyulozno-bumazhnykh materialov. Materialy I Mezhdunarodnoy nauchno-tekhnicheskoy konferentsii. [Problems of mechanics of pulp and paper materials. Materials of the I International Scientific and Technical Conference]. Arkhangelsk, 2011, pp. 207–209. (in Russ.).

Yeshbayeva U.Zh., Rafikov A.S. Poligrafiya, 2013, no. 8, pp. 52–56. (in Russ.).

Frolov M.V. Strukturnaya mekhanika bumagi. [Structural mechanics of paper]. Moscow, 2002, 274 p. (in Russ.).

Chernaya I.V. Teoriya i tekhnologiya kleyenykh vidov bumagi i kartona: monografiya. [Theory and technology of glued types of paper and cardboard: monograph]. Minsk, 2009, 394 p. (in Russ.).

Vurasko A.V., Shapovalova I.O. Prokleyka bumazhnoy massy. Uch.-met. pos. [Paper pulp gluing. Teaching aid]. Yekaterinburg, 2015, p. 4. (in Russ.).

Gavrilova N.N., Nazarov V.V. Analiz poristoy struktury na osnove adsorbtsionnykh dannykh: ucheb. posobiye. [Anal-ysis of the porous structure based on adsorption data: a tutorial]. Moscow, 2015, 132 p. (in Russ.).

Copyright (c) 2022 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.