ON THE PROSPECTS OF PROCESSING HEMP HUSK INTO A CELLULOSE PRODUCT

UDC 66.094.6: 661.123:676.166.3

Abstract

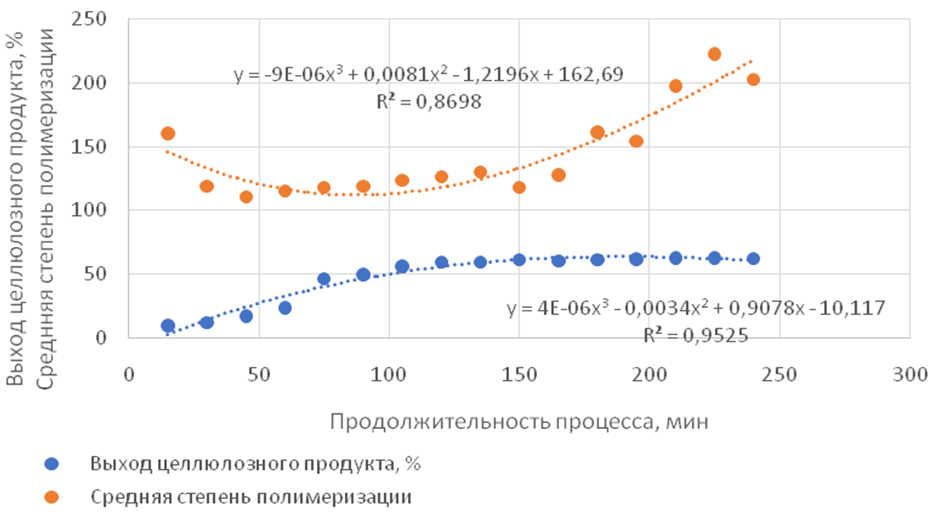

Technical hemp seeds are a source of valuable oil and biologically active substances. With the growth of their production and processing, the volume of secondary raw materials also increases, including the husk remaining after the collapse of hemp seeds. The purpose of this study is to obtain cellulose from hemp husk and characterize the cellulose product. Hemp husk is a mixture of the seed coat and the remnants of the kernel. The studied husk contained 7.7% of the core fraction. The cellulose content in the raw material was 40.8%, lignin – 28.7%. The content of water-soluble compounds varied in the range of 19–20%. The amount of extractives (in ethyl alcohol) was 4.6%. The cellulose product was obtained using peroxide treatment and a combined method combining enzyme and peroxide treatment of raw materials. The yield of the product was 32–37%, the content of cellulose in it was from 80 to 96%, the degree of polymerization was 170–200, the content of crystalline cellulose was 47–57%. It was found that during the peroxide treatment, the product yield after 120 minutes of the process did not change; the degree of polymerization decreased and began to grow steadily after 150 min, which can be explained by the recrystallization of the amorphous fraction. The conducted IR spectroscopic study indicates a low content of non-cellulose components in the target product. The paper shows the possibility of obtaining basic cellulose raw materials for the production of purified cellulose.The cellulose product obtained from hemp husk is characterized by a low content of crystalline cellulose, as a result of which it is a promising raw material for the production of powdered cellulose.

Downloads

Metrics

References

Belaya A. Agroinvestor, 2019, no. 5. URL: https://agroinvestor.ru/companies/article/31689-i-v-pir-i-v-mir/. (in Russ.).

Natsional'noye agrarnoye agentstvo. Konoplya vozvrashchayetsya: Rossiya pokoryayet mirovoy rynok. [National Agrarian Agency. Hemp returns: Russia conquers the world market]. URL: https://rosng.ru/post/konoplya-vozvraschaetsya-rossia-vyhodit-na-mirovoy-rynok. (in Russ.).

Gosudarstvennyy reyestr selektsionnykh dostizheniy, dopushchennykh k ispol'zovaniyu. T. 1. Sorta rasteniy (ofitsi-al'noye izdaniye). [State register of selection achievements approved for use. Vol. 1. Varieties of plants (official edi-tion)]. Moscow, 2021, 719 p. (in Russ.).

Kalashnikova L.I., Ovchinnikova A.A., Aleksandrova A.V., Kalashnikova A.A. Vektor nauki Tol'yattinskogo gosu-darstvennogo universiteta, 2011, no. 4 (18), pp. 32–34. (in Russ.).

Shayakhmetova A.Kh., Timerbayeva A.L., Borisova R.V. Vestnik Kazanskogo tekhnologicheskogo universiteta, 2015, vol. 18, no. 2, pp. 243–246. (in Russ.).

Zhao J., Xua Y., Wang B.W., Griffinc J., Rozeboomd K., Wanga D. Full, 2020, vol. 281, 118725. DOI: 10.1016/j.fuel.2020.118725.

Viscusi G., Barra G., Gorrasi G. Cellulose, 2020, vol. 27(5), pp. 8653–8665. DOI: 10.1007/s10570-020-03406-0.

Aleksandrov A.A., Pechenyy Ye.A., Nuriyev N.K., Momzyakova K.S., Deberdeyev R.Ya., Valishina Z.T. Vestnik tekhno-logicheskogo universiteta, 2020, vol. 23, no. 11, pp. 34–37. (in Russ.).

Ji A., Jia L., Kumar D., Yoo C.G. Fermentation, 2021, vol. 7, p. 6. DOI: 10.3390/fermentation7010006.

Vurasko A.V., Minakova A.R., Driker B.N., Sivakov V.P., Kosacheva A.M. Khimiya rastitel'nogo syr'ya, 2010, no. 2, pp. 165–168. (in Russ.).

Sinitsyn A.P., Sinitsyna O.A. Uspekhi biologicheskoy khimii, 2021, vol. 61, pp. 347–414. (in Russ.).

Aleyeva S.V., Lepilova O.V., Koksharov S.A. Zhurnal prikladnoy spektroskopii, 2021, vol. 88, no. 4, pp. 603–610. (in Russ.).

Abraham R.E., Wong C.S., Puri M. Materials, 2016, vol. 9, p. 562. DOI: 10.3390/ma9070562.

Barana D., Salanti A., Orlandi M., Ali D.S., Zoia L. Industrial Crops and Products, 2016, vol. 86, pp. 31–39.

Gismatulina Yu.A., Budayeva V.V. Polzunovskiy vestnik, 2016, vol. 1, no. 4, pp. 174–178. (in Russ.).

Maurya D.P., Singla A., Negi S. 3 Biotech., 2015, vol. 5(5), pp. 597–609. DOI: 10.1007/s13205-015-0279-4.

Chaturvedi V., Verma P. 3 Biotech., 2013, vol. 5, pp. 415–431.

Woiciechowski A.L., Neto C.J.D., Vandenberghe L.P.S., Neto D.P.C., Sydney A.C.N., Letti L.A.J., Karp S.G., Torres L.A.Z., Soccol C.R. Bioresource Technology, 2020, vol. 304, 122848. DOI: 10.1016/j.biortech.2020.122848.

Pavlov I.N. Polzunovskiy vestnik, 2018, no. 1, pp. 148–152. (in Russ.).

Putra Z.A. Indonesian Journal of Science & Technology, 2018, vol. 3, pp. 75–81.

Kim K., Hong J. Bioresource Technology, 2001, vol. 77, pp. 139–144.

Kuznetsov B.N., Garyntseva N.V., Sudakova I.G., Skripnikov A.M., Pestunov A.V. Khimiya rastitel'nogo syr'ya, 2021, no. 4, pp. 95–107. DOI: 10.14258/jcprm.20210410504. (in Russ.).

Garyntseva N.N., Sudakova I.G., Kuznetsov B.N. Zhurnal SFU. Khimiya, 2015, no. 3, pp. 422–429. (in Russ.).

GOST 10857-64. Semena maslichnyye. Metody opredeleniya maslichnosti. [GOST 10857-64. Oilseeds. Methods for determining oil content]. Moscow, 2010, 6 p. (in Russ.).

GOST 13496.4-2019. Korma, kombikorma, kombikormovoye syr'ye. Metody opredeleniya soderzhaniya azota i syrogo proteina. [GOST 13496.4-2019. Feed, compound feed, compound feed raw materials. Methods for determining the content of nitrogen and crude protein]. Moscow, 2019, 22 p. (in Russ.).

GOST 10856-96. Semena maslichnyye. Metod opredeleniya vlazhnosti. [GOST 10856-96. Oilseeds. Moisture deter-mination method]. Moscow, 2010, 6 p. (in Russ.).

GOST 26226-95. Korma, kombikorma, kombikormovoye syr'ye. Metody opredeleniya syroy zoly. [GOST 26226-95. Feed, compound feed, compound feed raw materials. Methods for determining raw ash]. Minsk, 2003, 8 p. (in Russ.).

Obolenskaya A.V., Yel'nitskaya Z.P., Leonovich A.A. Laboratornyye raboty po khimii drevesiny i tsellyulozy. [Labor-atory work on the chemistry of wood and cellulose]. Moscow, 1991, 320 p. (in Russ.).

Schultz C.J., Lim W.L., Khor S.F., Neumann K.A., Schulz J.M., Ansari O. et al. J. Agric. Food Res., 2020, vol. 2, 100025. DOI: 10.1016/j.jafr.2020.100025.

Ioyelovich M.Ya. Vysokomolekulyarnyye soyedineniya. Ser. A, 2016, vol. 58(6), pp. 604–624. (in Russ.).

Barbash V., Karakutsa M., Trembus J., Yashenko O. Eastern-European Journal of Enterprise Technologies, 2016, vol. 38, pp. 51–56. DOI: 10.15587/1729-4061.2016.71275.

Tyukavkina N.A., Baukov Yu.I. Bioorganicheskaya khimiya: uchebnik dlya vuzov. [Bioorganic chemistry: a textbook for universities]. Moscow, 2005, 542 p. (in Russ.).

Nechiporenko A.P., Vezo O.S., Nechiporenko U.Yu., Plotnikova L.V., Sitnikova V.Ye.,Ukraintseva P.I., Plot-nikov P.P. Izvestiya vuzov. Prikladnaya khimiya i biotekhnologiya, 2021, vol. 11, no. 4, pp. 627–641. DOI: 10.21285/2227-2925-2021-11-4-627-641. (in Russ.).

Copyright (c) 2023 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.