SULPHATE COOKING OF THE DEAD SOFT WOOD

UDC 676.032

Abstract

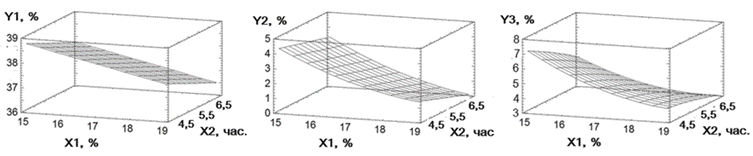

The samples of dead wood (the pine, spruce, fir, cedar), damaged in 2017 by the siberian silkmoth and cedar-tree borer is displayed at April 2022 on the Yenisei region of Krasnoyarsk Territory with for sulphate delignification, optimization of the cooking process, estimation of the unbleached cellulose characteristics, determination of the possibility of its use as fibrous semi-finished product of cellulose-paper production. The sulphate cookings are executed in laboratory autoclave under the following constant conditions: hydromodule 4.8; the degree sulfiditiy of the cooking solution 20.8%; the temperature 170 °C. In the course of experiment varied the active alkali consumption (15.5–18.5% from wood mass in unit Na2O) and duration of the isothermal cooking (4.5–6.5 hours). The dependencies of the output and of the cellulose characteristics from these factor is approximated by the regression equations of the second order. Mathematical model of the cookig process obtained such way is used for graphic presentation result in type of the three-dimensional surfaces of the response and for calculation of the best values of the variable cooking factor: consumption active alkali 16.2%; cooking duration 6.1 hour. All samples of the wood was be cooking separately on optimal regime. The cooking results: the cellulose output 37.9–41.3%; the no-cooked part less 1%; degree of the cellulose delignification 23–29 Kаppа unit (the mass part of the lignin 3.38–4.21%); the explosive length 8130– 9250 m; the forcing through resistance 400–490 кPа; tearing resistance 630–870 mmN; break resistance 380–460 bends. The characteristic of the all cellulose samples answer to the mark NS-3. It is noted significant reduction of the cellulose output (on 10–2%) in comparison with cellulose similar degree delignification from sound wood.

Downloads

Metrics

References

Zherebov L.P., Komarovskiy V.N. Trudy TsNIILKhI, 1933, no. 11, pp. 39–52. (in Russ.).

Komarov F.P. Bumazhnaya promyshlennost', 1934, no. 2, pp. 49–60. (in Russ.).

Dobrovol'skiy D.S. IVUZ. Lesnoy zhurnal, 1959, no. 6, pp. 145–150. (in Russ.).

Morozova O.V., Ivanova R.P., Kozlov V.N. Izv. AN SSSR, 1960, no. 3, pp. 45–49. (in Russ.).

Bjorkman E., Forssblad L., Malm E. Studia forestalia suecica, 1964, no. 20, 40 р.

Ushakov N.I. Tsellyuloza, bumaga, karton, 1971, no. 7, pp. 9–11. (in Russ.).

Conner R.N., Miller O.K., Adkisson C.S. The Wilson Bulletin, 1976, vol. 88(4), pp. 575–581.

Korzhitskaya Z.A., Vasil'yeva N.A. Fiziko-khimicheskiye issledovaniya drevesiny i yeyo kompleksnoye ispol'zovaniye. [Physico-chemical studies of wood and its complex use]. Petrozavodsk, 1978, pp. 38–52. (in Russ.).

Matyushkina A.P., Ageyeva M.I. Fiziko-khimicheskiye issledovaniya drevesiny i yeyo kompleksnoye ispol'zovaniye. [Physico-chemical studies of wood and its complex use]. Petrozavodsk, 1978, pp. 24–38. (in Russ.).

Farris K.L., Hiss M.J., Zack S. The Condor, 2004, vol. 106, pp. 50–59.

Sevast'yanova Yu.V., Fetyukova N.I., Nevzorova I.M. IVUZ. Lesnoy zhurnal, 2014, no. 1, pp. 133–138. (in Russ.).

Korotayev G.Ye., Sevast'yanova Yu.V., Fetyukova N.N. Lesnoy zhurnal, 2013, no. 1, pp. 146–151. (in Russ.).

Varfolomeyev Yu.A. IVUZ. Lesnoy zhurnal, 2005, no. 4, pp. 151–153. (in Russ.).

Voronin V.V. O lesozashchitnom rayonirovanii Arkhangel'skoy oblasti. [On forest protection zoning of the Arkhan-gelsk region]. Arkhangelsk, 2007, pp. 60–65. (in Russ.).

Fedorov I.A. LesPromInform, 2005, no. 8(30), pp. 42–44. (in Russ.).

Belyayev I.N. Aktual'nyye problemy razvitiya lesnogo kompleksa: materialy Mezhdunar. nauchno-tekhn. konf. [Actual problems of development of the forest complex: мaterials of the International scientific and technical conf.]. Vologda, 2008, pp. 6–8. (in Russ.).

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva: spravochnyye materialy. V 3 tomakh. T. 1. Syr'yo i proiz-vodstvo polufabrikatov. Chast' 1. [Technology of pulp and paper production. Reference materials. In 3 volumes. Vol. 1. Raw materials and production of semi-finished products. Part 1]. St. Petersburg, 2002, 425 p. (in Russ.).

Pen R.Z., Pen V.R. Statisticheskiye metody matematicheskogo modelirovaniya, analiza i optimizatsii tekhnolo-gicheskikh protsessov. [Statistical methods of mathematical modeling, analysis and optimization of technological pro-cesses]. St. Petersburg, 2020, 308 p. (in Russ.).

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva: spravochnyye materialy. V 3 tomakh. T. 1. Syr'yo i proiz-vodstvo polufabrikatov. Chast' 2. [Technology of pulp and paper production. Reference materials. In 3 volumes. Vol. 1. Raw materials and production of semi-finished products. Part 2]. St. Petersburg, 2003, 633 p. (in Russ.).

Copyright (c) 2023 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.