IMPROVING THE PROCESS OF SPECIAL PURPOSE FIBREBOARD

Abstract

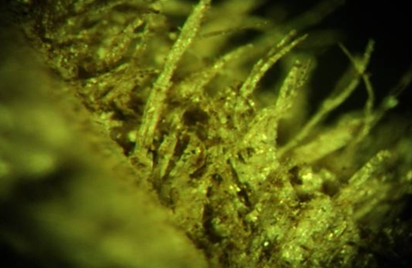

The results of studies of physical and mechanical properties of fiberboard production by dry method (MDF) using presmasse vermiculite concentrate and expanded vermiculite. It was found that the use of vermiculite in the manufacture of the plates produces Fire resistant MDF, fiber savings, reducing the density of the plate, improves durability at a static bend, decreases the cost of the plates.

Object of research – getting fiberboard special purpose dry process production.

Subject of research – the process of preparation of semi-finished products in the preparation of fibreboard with reduced fire hazard.

Objective – To develop the scientific basis of reduce fire danger fibreboard made by dry method.

The process of grinding the wood fiber supply in knife grinding machines depends on their design and process parameters. Morphological properties developed fibers, in turn, also have a significant effect on the properties of the finished product. Since the processes of obtaining Fire resistant boards with the right physical and mechanical properties are currently not enough substantiated theoretically and basically solved in a practical way, in the following tasks:

- Determine the composition of the special manufacturing techniques in presmass Fire resistant hardboard dry process production;

- Determine the effect of flame retardant components and quality characteristics of wood-fiber semi-finished products on the physico-mechanical properties of the finished boards with a reduced fire hazard.

Downloads

Metrics

References

Чистова Н.Г. Переработка древесных отходов в технологическом процессе получения древесноволокнистых плит : дис. … докт. техн. наук. Красноярск, 2010. 415 с.

Леонович А.А., Шелоумов А.В. Снижение пожарной опасности древесных материалов, изделий строительных конструкций. СПб., 2002. 59 с.

Пижурин А.А., Пижурин А.А. Моделирование и оптимизация процессов деревообработки. М., 2004. 375 с.

Заявка на патент № 2009613683 (РФ). Численный метод определения секундной режущей длины секторной ножевой гарнитуры дисковых мельниц с параллельными прямолинейными ножами постоянной ширины / А.А. Набиева, Е.Е. Нестеров, Ю.Д. Алашкевич, Д.С. Карпенко // 10.07.2009.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.