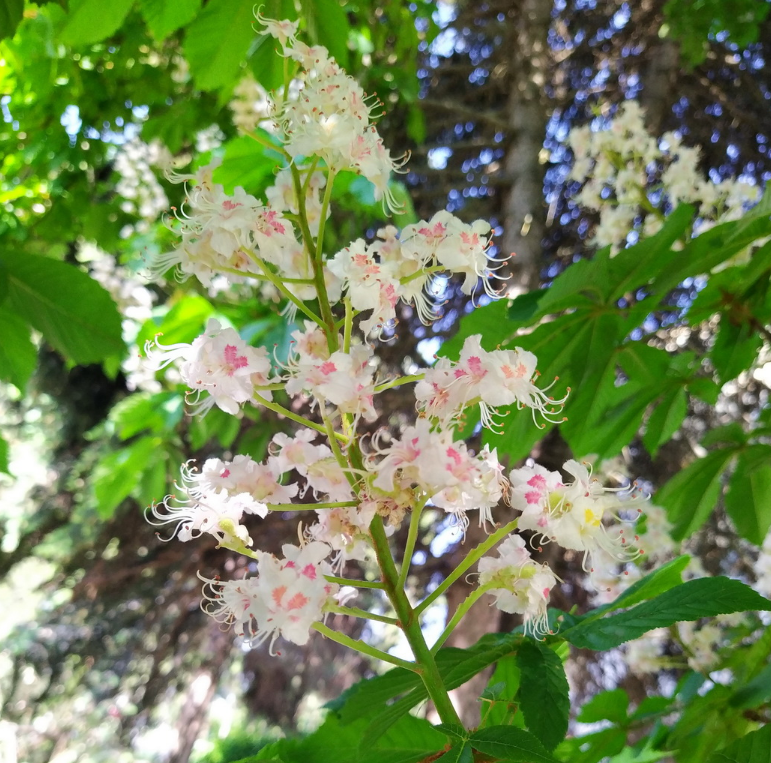

OPTIMIZATION OF THE EXTRACTION PROCESS OF HORSE CHESTNUT (AESCULUS HIPPOCASTANUM L.) POLYSACCHARIDES

UDK 547.4:577.1:576.8

Abstract

The results of the development of optimal parameters for the extraction process of polysaccharides isolated from the shells of horse chestnut fruits collected on the territory of Tashkent and the Tashkent region of the Republic of Uzbekistan are presented. To identify the optimal indicators affecting the extraction processes, the influence of the following parameters on the yield of polysaccharides was studied: the ratio of raw materials: extractant, the extraction rate, the extraction temperature, the degree of evaporation. It has been established that at ratios of raw materials : extractant of 1 : 30, the highest yield of the final product is observed leads to a significant increase in the yield of the final product. The influence of the temperature regime on the yield of polysaccharides was carried out in the temperature range from 25 to 120 °С. At the same time, under constant conditions of the bath modulus of 1 : 30 and the duration of extraction of 2 hours with varying temperature, the highest yield of polysaccharides is observed at a temperature of 95 °С. The optimal degree of evaporation of the extract, in which no large losses of the final product are observed, is the degree of evaporation by 4 times. To assess the influence of technological parameters on the change in qualitative or quantitative indicators of the quality of PS, a one-way analysis of variance was studied for each experiment. Analysis of variance showed the significance of the Fisher criterion, since the p-value is less than 0.05, therefore, the influence of the studied parameters on the yield of polysaccharides can be considered proven. Keywords: extraction, aqueous fraction, extractant, analysis of variance.

Downloads

Metrics

References

Azimova L.B., Normakhamatov N.S., Khaytmetova S.B., Mukhitdinov B.I., Filatova A.V., Amonova D.M., Khalilova G.A., Kirgizbayev Kh.Kh., Turayev A.S. Khimiya rastitel'nogo syr'ya, 2019, no. 2, pp. 35–41. DOI: 10.14258/jcprm.2019024491. (in Russ.).

Men'shutina N.V., Kazeyev I.V., Khudeyev I.I., Artem'yev A.I., Flegontov P.A., Dashkin R.R. Izvestiya VUZov. Khimiya i khimicheskaya tekhnologiya, 2022, vol. 65, no. 4, pp. 22–28. (in Russ.).

Mel'nikova N.B., Solov'yeva O.N., Kochetkov Ye.N. Izvestiya VUZov. Khimiya i khimicheskaya tekhnologiya, 2019, vol. 62, no. 10, pp. 4–29. DOI: 10.6060/ivkkt.20196210.591. (in Russ.).

Akhmedov O.R., Sokhibnazarova Kh.A., Shomurotov Sh.A. Khimiya rastitel'nogo syr'ya, 2017, no. 3, pp. 227–231. DOI: 10.14258/jcprm.2017031729. (in Russ.).

Gregori А., Pohleven J. Food Tech. Biotech., 2007, vol. 45, p. 238.

Pan F., Su T.J., Liu Y., Hou K., Chen C., Wu W. International Journal of Biological Macromolecules, 2018, vol. 112, pp. 1073–1083. DOI: 10.1016/j.ijbiomac.2018.02.070.

Samanta S., Maity K., Nandi A.K., Sen I.K., Devi K.S.P., Mukherjee S. et al. Carbohydrate Research, 2013, vol. 367, pp. 33–40. DOI: 10.1016/j.carres.-2012.12.002.

Wang Y., Liu Y., Yu H., Zhou S., Zhang Z., Wu D. et al. Carbohydrate Polymers, 2017, vol. 167, pp. 337–344. DOI: 10.1016/j.carbpol.2017.03.016.

Olennikov D.N., Kashchenko N.I. Khimiya rastitel'nogo syr'ya, 2014, no. 1, pp. 5–26. DOI: 10.14258/jcprm.1401005. (in Russ.).

Fiorito S. et al. Phytochemistry, 2018, vol. 153, pp. 1–10. DOI: 10.1016/j.phytochem.2018.05.008.

Jiao R. et al. The American J. of Chinese Medicine, 2016, vol. 44(3), pp. 463–488. DOI: 10.1142/S0192415X16500269.

Qu J. et al. International J. of Biological Macromolecules, 2020, vol. 161, pp. 24–64. DOI: 10.1016/j.ijbiomac.2020.05.196.

Laksayeva Ye.A., Davydov V.V., Kyarimov I.A., Kukhtenkova Ye.A., Arushanova V.V., Zlobina Ye.A. Izvestiya Sa-ratovskogo universiteta. Novaya seriya. Seriya: Khimiya. Biologiya. Ekologiya, 2019, vol. 19, no. 2, pp. 216–222. DOI: 10.18500/1816-9775-2019-19-2-216-222. (in Russ.).

Khaytmetova S.B., Turayev A.S., Khalilova G.A. i dr. Eksperimental'naya i klinicheskaya farmakologiya, 2022, vol. 85, no. 12, pp. 38–41. DOI: 10.30906/0869-2092-2022-85-12-38-41. (in Russ.).

Besednova N.N., Zaporozhets T.S., Kuznetsova T.A., Kryzhanovskiy S.P., Kovalev N.N., Zvyagintseva T.N. Antibi-otiki i khimioterapiya, 2014, vol. 59, no. 3–4, pp. 30–37. (in Russ.).

Vandyshev V.V. Meditsinskaya pomoshch', 2002, no. 5, pp. 36–38. (in Russ.).

Chistyakova A.S., Sorokina A.A., Dunilin A.D., Gudkova A.A., Bolgov A.S. Farmatsiya, 2021, vol. 70, no. 7, pp. 32–36. DOI: 10.29296/25419218-2021-07-05. (in Russ.).

Sambukova T.V. Fitofarmakologiya, 2017, vol. 15, no. 2, pp. 56–63. (in Russ.).

Savchenko L.N., Marinina T.F., Karpenko V.A., Saushkina A.S. Izvestiya Samarskogo nauchnogo tsentra RAN, 2021, no. 2(5), pp. 612–617. (in Russ.).

Maloshtan L.N. Klinichna farmatsiya, 2011, vol. 15, no. 4, pp. 57–59. (in Russ.).

Nielsen S.S. Food Analysis Laboratory Manual. Food Science Texts Series. Springer, Boston, MA, 2010. DOI: 10.1007/978-1-4419-1463-7_6.

Gashevskaya A.S. Uspekhi sovremennogo yestestvoznaniya, 2017, no. 4, pp. 12–18. (in Russ.).

Xia Y.G., Sun H.M., Wang T.L., Liang J., Yang B.Y., Kuang H.X. Molecules, 2018, vol. 3(6), p. 1284. DOI: 10.3390/molecules23061284.

Chichoyan N. Georgian Medical News, 2009, vol. 1(176), pp. 74–77.

Da Silva D.F., Ogawa C.Y.L., Sato F., Neto A.M., Larsen F.H., Matumoto-Pintro P.T. Powder Technology, 2020, vol. 361, pp. 610–616. DOI: 10.1016/j.powtec.2019.11.071.

Copyright (c) 2024 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.