RHEOLOGICAL CHARACTERISTICS OF A LIQUID WOOD-POLYMER COMPOSITE FOR THE PRODUCING OF DETAILS BY LAYER-BY-LAYER MOLDING

UDC 678.02

Abstract

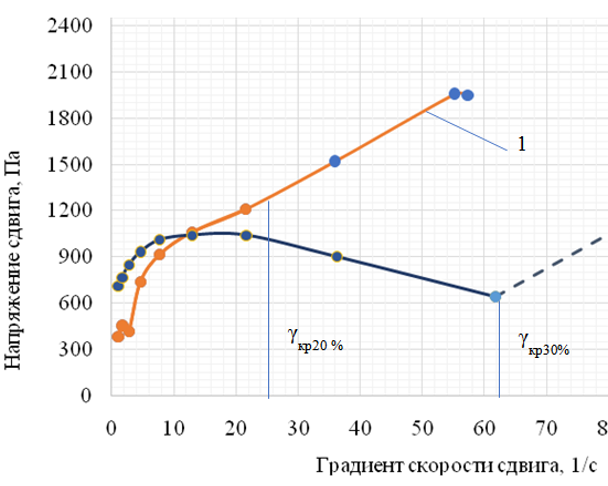

The article presents studies of rheological characteristics of a liquid wood-polymer composite material included wood flour (as part of a pine particle), epoxy resin with a hardener. Viscosity measurements were carried out using a rotary viscometer at various concentrations of the solid phase in the composite material. The relationship between the shear stress and the shear rate gradient is established. The analysis of rheological characteristics showed that the composite material exhibits both Newtonian and non-Newtonian properties of the liquid at concentrations below 30%, at a temperature of 20 °C. The boundaries of the transition to the lowest Newtonian viscosity are established and the yield limits at concentrations of the solid phase exceeding 20% are determined. The obtained rheological characteristics can be used to calculate the extruder feed channels in 3D printers, in order to prevent their clogging, when applying the composite in liquid form in layers.

Downloads

Metrics

References

Tager A.A. Fiziko-khimiya polimerov: 4-ye izd., ispravlennoye i dopolnennoye. [Physicochemistry of Polymers: 4th ed., revised and supplemented]. Moscow, 2007, 573 p. (in Russ.).

Zakharov A.G. Nauchnyye osnovy khimicheskoy tekhnologii uglevodov. [Scientific foundations of chemical technology of carbohydrates]. Moscow, 2008, 528 p. (in Russ.).

Akim E.L., Pekarets A.A., Rogovina S.Z., Berlin A.A. Polymer Science, Series D, 2021, vol. 14, no 1, pp. 102–105.

Pekarets A.A. i dr. Izvestiya vysshikh uchebnykh zavedeniy. Lesnoy zhurnal, 2020, vol. 373, no. 1, pp. 200–208. (in Russ.).

Leonovich A.A. Novyye drevesnoplitnyye materialy. [New wood-based materials]. St. Petersburg, 2008, 160 p. (in Russ.).

Leonovich A.A. Tekhnologiya drevesnykh plit: progressivnyye resheniya: uchebnoye posobiye. [Technology of wood boards: progressive solutions: a tutorial]. St. Petersburg, 2005, 208 p. (in Russ.).

Leonovich A.A. Fiziko-khimicheskiye osnovy obrazovaniya drevesnykh plit. [Physicochemical bases of formation of wood boards]. St. Petersburg, 2003, 192 p. (in Russ.).

Terent'yev O.A. Gidrodinamika voloknistykh suspenziy v tsellyulozno-bumazhnom proizvodstve. [Hydrodynamics of fibrous suspensions in pulp and paper production]. Moscow, 1980, 248 p. (in Russ.).

Kurov V.S., Kokushin N.N. Mashiny dlya proizvodstva bumagi i kartona. [Machines for the production of paper and cardboard]. St. Petersburg, 2017, 646 p. (in Russ.).

Totukhov Yu.A., Antuf'yev S.V., Smirnova E.A. Gidrogazodinamika: uchebno-prakticheskoye posobiye. [Hydro-gasdynamics: educational and practical manual]. St. Petersburg, 2019, 62 p. (in Russ.).

Govyadin I.K., Chubinskiy A.N. Izvestiya vysshikh uchebnykh zavedeniy. Lesnoy zhurnal, 2020, vol. 374, no. 2, pp. 129–145. (in Russ.).

Govyadin I.K., Chubinskiy A.N. Izvestiya Sankt-Peterburgskoy lesotekhnicheskoy akademii, 2019, vol. 229, no. 1, pp. 231–242. (in Russ.).

Midukov N.P., Kurov V.S., Yevdokimov N.V. Khimicheskiye volokna, 2023, no. 1, pp. 66–72. (in Russ.).

Yevdokimov N.V., Midukov N.P., Kurov V.S., Staritsyn M.V., Petrov S.N. Khimicheskiye volokna, 2022, no. 3, pp. 38–43. (in Russ.).

Liu T., Leusheva E., Morenov V., Li L., Jiang G., Fang C., Zhang L., Zheng S., Yu Y. Energies, 2020, vol. 13, 16 p.

Beloglazov I., Morenov V., Leusheva E., Gudmestad O.T. Energies, 2021, vol. 14, 15 p.

GOST 1929-87. Metod opredeleniya dinamicheskoy vyazkosti na rotatsionnom viskozimetre. [GOST 1929-87. Method for determining dynamic viscosity using a rotational viscometer]. Moscow, 1988, 18 p. (in Russ.).

Barnes H.A. A Handbook of elementary rheology. institute of non-newtonian fluid mechanics. Aberystwyth, 2000, 568 p.

Ellwood R.J., Georgiou G.C., Papanastasiou T.C., Wilkes J.O. J. Rheol., 1990, vol. 34, pp. 787–812.

Moshev V.V., Ivanov V.A. Reologicheskoye povedeniye kontsentrirovannykh nen'yutonovskikh suspenziy. [Rheologi-cal behavior of concentrated non-Newtonian suspensions]. Moscow, 1990, 87 p. (in Russ.).

Volfson S.I., Fayzullin I.Z., Musin I.N., Fayzullin A.Z., Grachev A.N., Pushkin S.A. Plasticheskie Massy, 2015, vol. 5, pp. 39–43.

Lv X., Hao X., Ou R., Liu, T., Guo C., Wang Q., Yi X., Sun L. Forests, 2021, vol. 417, no. 12, 12 p.

Kirchhoff N., Schröder C., Stute D., Moritzer E., Schmid H. Chem. Ing. Tech., 2012, vol. 84, pp. 1584–1589.

Sarabi M.T., Behravesh A.H., Shahi P., Daryabari Y. Thermoplast. Compos., 2014, vol. 27, pp. 881–894.

Okisheva M.K., Abramov A.A., Tsygankov P.Yu. Uspekhi v khimii i khimicheskoy tekhnologii, 2021, vol. 35, no. 10, pp. 98–100. (in Russ.).

Patent 220692 (RU). 2023. (in Russ.).

Copyright (c) 2024 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.