ADVANCED PRODUCTION TECHNOLOGY OF HIGH PURITY ARABINOGALACTAN

Abstract

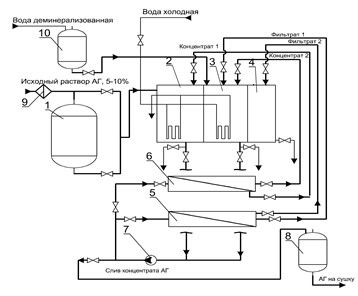

The technology of larch wood arabinogalactan production, combined with the preparation of dihydroquercetin, has been developed. The improved process includes the following steps: extraction of larch raw material with hot water (80–90 °C) after extraction of dihydroquercetin from it; purification of the obtained extract from high-molecular impurities by ultrafiltration using a hydrophobic membrane; concentration and additional purification of the extract from low molecular weight phenolic impurities by diafiltration using a hydrophilic membrane; spray drying of the concentrate. The concentrate drying parameters are optimized. The improved technology makes it possible to obtain a product with a main substance content ≥98%, to exclude the use of imported reagents – flocculants, and, therefore, the expenses of separation from clarified extract cake and its utilization are eliminated. Undoubted advantages of the developed technology are the reduction of the purification time of the extract, as well as the ability to automate the process of AG production and realize it in a continuous mode, that increase the feasibility and economic efficiency of the process, as well as to increase the exploitation time of the hydrophilic membrane, and to reduce energy costs.

Downloads

Metrics

References

Babkin V.A., Ostroukhova L.A., Trofimova N.N. Biomassa listvennitsy: ot khimicheskogo sostava do innovatsi-onnykh produktov. [Larch biomass: from chemical composition to innovative products]. Novosibirsk, 2011, 236 p. (in Russ.).

Dushkin A.V., Meteleva E.S., Tolstikova T.G., Tolstikov G.A., Poliakov N.E., Neverova N.A., Medvedeva E.N., Bab-kin V.A. Izvestiia RAN. Ser. Khim., 2008, no. 6, pp. 1274–1282. (in Russ.).

Tolstikova T.G., Khvostov M.V., Bryzgalov A.O., Dushkin A.V., Tolstikov G.A. Doklady akademii nauk, 2010, vol. 433, no. 5, pp. 713–714. (in Russ.).

Babkin V.A., Malkov Yu.A., Medvedeva E.N., Trofimova N.N., Ivanova N.V. Russian Journal of General Chemistry, 2012, vol. 82, no. 5, pp. 955–962.

Patent 2002756 (RU). 1993. (in Russ.).

Patent 2040268 (RU). 1995. (in Russ.).

Patent 2273646 (RU). 2006. (in Russ.).

Patent 2280040 (RU). 2006. (in Russ.).

Patent 2413432 (RU). 2011. (in Russ.).

Mel'nikov V.A., Suntsova L.P., Dushkin A.V., Chepurin S.P., Shelepov V.G. Khimiia v interesakh ustoichivogo razvitiia, 2015, vol. 23, no. 5, pp. 561–565. (in Russ.).

Patent 2143437 (RU). 1999. (in Russ.).

Patent 2228943 (RU). 2004. (in Russ.).

Patent 2384587 (RU). 2010. (in Russ.).

Patent 2256668 (RU). 2005. (in Russ.).

Otchet ob eksperimental'nom doklinicheskom izuchenii bezopasnosti i farmakologicheskoi aktivnosti sub-stantsii «Fibrolar®» proizvodstva OOO INPF «Khimiia drevesiny» (g. Irkutsk). [Report on the experimental preclinical study of the safety and pharmacological activity of the substance "Fibrolar®" produced by OOO INPF "Chemistry of Wood" (Irkutsk)] Sankt-Peterburg: FGUN «Institut toksikologii» FMBA Rossii, 2010, 145 p. (in Russ.).

Medvedeva E.N., Ostroukhova L.A., Neverova N.A., Onuchina N.A., Babkin V.A. Khimiya Rastitel'nogo Syr'ya, 2011, no. 1, pp. 45–48. (in Russ.).

Patent 2447086 (RU). 2012. (in Russ.).

Patent 2079349 (RU). 1997. (in Russ.).

Antonova G.F., Tiukavkina N.A. Khimiia drevesiny, 1976, no. 4, pp. 60–62. (in Russ.).

Medvedeva E.N., Babkin V.A., Makarenko O.A., Nikolaev S.M., Khobrakova V.B., Shulunova A.M., Fedorova T.E., Es'kova L.A. Khimiya Rastitel'nogo Syr'ya, 2004, no. 4, pp. 17–23. (in Russ.).

Patent 2454429 (RU). 2012. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.