VORTEXGAS-LIQUIDSEPARATOR

Abstract

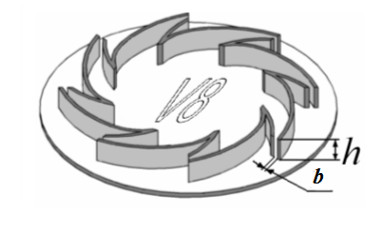

Results of a research of the vortex contact device of the tangential type intended for separation of drops and cleaning of industrial emissions of gaseous inclusions in rectifying and absorbing columns, hydrolysis devices, dryers, evaporators, scrubbers, gas-liquid reactors are presented. In which removal of disperse particles from a stream and absorption of components of gas is carried out directly in the rotating gas-liquid layer of absorbent in the field of the greatest influence of forces of inertia and a high-speed pressure of gas. What allows to reach the high speed of the movement of a gas stream and to provide catching of drops up to 0.4 kg on one kilogram of air. In work, two types of zavikhritel are investigated and the main modes of interaction of gas with liquid bubbling and ring are revealed. The size of coefficient of hydraulic resistance of the contact device was equal 0.8–1.1, and a share of a bryzgounos – less than 0.01. It is established that at an expense of drops in a gas stream up to 0.01 kg/s, the size of coefficient of resistance has increased by 1.25 times. Values of superficial coefficient of a massootdacha at gas absorption by liquid are reached equal to 0.9·10-3 m/c., and the interphase surface has made equal 0.1–0.9·10-3 m/c.

Advantage of the specified device is his steady and effective work in the wide range of loadings on gas, liquid, rather low hydraulic resistance, and small metal consumption. Dependences for determination of gas content, angular and linear speed, height of the rotating layer of liquid and size of coefficients of a massootdacha allowing to carry out calculation of industrial samples of the corresponding equipment are presented.

Downloads

Metrics

References

Khol'kin Iu.I. Tekhnologiia gidroliznykh proizvodstv. [Technology of hydrolysis productions]. Moscow, 1989, 496 p. (in Russ.).

Voinov N.A., Sugak E.V., Nikolaev N.A., Voronin S.M. Plenochnye bioreaktory. [Film bioreactors]. Krasnoiarsk, 2001, 252 p. (in Russ.).

Voinov N.A. Nikolaev N.A. Plenochnye trubchatye gazo-zhidkostnye reaktory. [Film tubular gas-liquid reactors]. Kazan', 2008, 272 p. (in Russ.).

Sugak E.V., Voinov N.A., Nikolaev N.A. Ochistka gazovykh vybrosov v apparatakh s intensivnymi gidrodinami-cheskimi rezhimami. [Purification of gas emissions in devices with intensive hydrodynamic regimes]. Kazan', 2009, 224 p. (in Russ.).

Lebediuk G.K., Val'dberg A.Iu., Gromov M.P., Prikhod'ko V.P. Kapleuloviteli i ikh primenenie v gazoochist-ke. Ob-zornaia informatsiia. [Drip eliminators and their application in gas cleaning. Overview information]. Moscow, 1974, 63 p. (in Russ.).

Prikhod'ko V.P., Safonov V.N., Lebediuk G.K. Tsentrobezhnye kaple uloviteli s lopastnymi zavikhriteliami. Obzornaia informatsiia. [Centrifugal drop catchers with lobed swirlers. Overview information]. Moscow, 1979, 50 p. (in Russ.).

Ovchinnikov A.A. Dinamika dvukhfaznykh zakruchennykh turbulentnykh techenii v vikhrevykh separatorakh. [Дина-мика двухфазных закрученных турбулентных течений в вихревых сепараторах]. Kazan', 2005, 288 p. (in Russ.).

Nikolaev A.N., Dmitriev A.V., Latypov D.N. Ochistka gazovykh vybrosov TES, rabotaiushchikh na tverdom i zhidkom toplive. [Purification of gas emissions of TPPs operating on solid and liquid fuels]. Kazan', 2004, 136 p. (in Russ.).

Nikolaev N.A. Effektivnost' protsessov rektifikatsii i absorbtsii v mnogostupenchatykh apparatakh s priamotochno-vikhrevymi kontaktnymi ustroistvami. [Efficiency of rectification and absorption processes in multistage apparatus with direct-vortex contact devices]. Kazan', 2011, 116 p. (in Russ.).

Sobin V.M., Ershov A.I. AN BSSR. Ser. Fizika energ. nauk, 1972, no. 3, p. 56. (in Russ.).

Korotkov Iu.F. Trudy Kazanskogo khimiko-tekhnologicheskogo instituta, 1970, no. 45, pp. 26–31. (in Russ.).

Ershov A.I., Plekhov I.M., Bershevits A.I. Novye konstruktsii separatorov dlia ochistki promyshlennykh gazov. [New designs of separators for cleaning industrial gases]. Minsk, 1973, 36 p. (in Russ.).

Idel'chik E.I. Spravochnik po gidravlicheskim soprotivleniiam. [Reference book on hydraulic resistance]. Moscow, 1992, 360 p. (in Russ.).

Margolin E.V. Vybor optimal'nykh parametrov vertikal'nogo kapleulovitelia. [Selecting the optimal parameters for the vertical drop eliminator]. Moscow, 1976, no. 3, pp. 11–13. (in Russ.).

Voinov N.A., Zhukova O.P., Lednik S.A., Nikolaev N.A. Teoreticheskie osnovy khimicheskoi tekhnologii, 2013, vol. 47, no. 1, pp. 1–6. (in Russ.).

Voinov N.A., Lednik S.A., Zhukova O.P. Khimiya Rastitel'nogo Syr'ya, 2011, no. 4, pp. 295–300. (in Russ.).

Voinov N.A., Lednik S.A., Zhukova O.P. Khimiya Rastitel'nogo Syr'ya, 2012, no. 4, pp. 209–213. (in Russ.).

Voinov N.A., Lednik S.A. Khimicheskaia promyshlennost', 2011, vol. 88, no. 5, pp. 250–256. (in Russ.).

Patent 2580727 (RU). 2016. (in Russ.).

Nikolaev N.A. Dinamika plenochnogo techeniia zhidkosti i massoperenos v usloviiakh sil'nogo vzaimodeistviia s gazom (parom) pri odnonapravlennom voskhodiashchem ili niskhodiashchem dvizhenii. [Dynamics of film flow of a liquid and mass transfer under conditions of strong interaction with gas (steam) with unidirectional ascending or de-scending motion]. Kazan', 2011, 104 p. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.