THE PREPARATION OF FIBERS FOR CARDBOARD PRODUCTION

Abstract

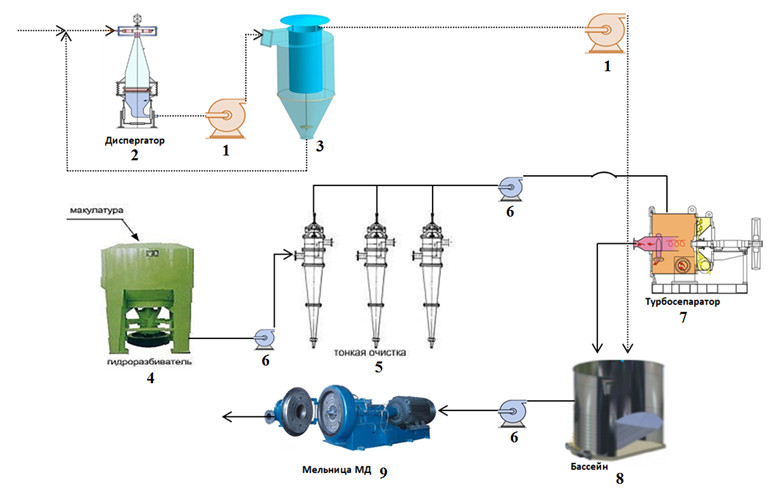

The article presents the data about the preparation of recovered paper using dry method. The objective of this method of fiber preparation is to reduce water and energy consumption as well as obtaining higher physical and mechanical characteristics of the cardboard. There is used a dispergator parts of which are constructed with 3D printer. After dry defibration, the purification is carried out. Acquired finely dispersed, refined material is used to produce the three-layer cardboard – test-liner. According to standard methodologies, there were determined such mechanical parameters of multi-layer test-liner as breaking length, bursting strength. Obtained results can be used to produce multi-layer testliner to reduce energy costs, as well as water consumption. As a result of this research, it turned out that using the method of preliminary dry dispersion of fibers, it becomes possible to reduce metal volume of the equipment as well as energy and water consumption. Previously, the mechanical grinding of recycled fibers was not carried out. Therefore the data presented in this article allow assess the cost of applying this method into the industry. The method of dry dispersion, which was carried out and studied in laboratory conditions, is not currently applied in the paper and cardboard industry of Russia, despite its advantages. In the future, it is planned to conduct repeated studies, with a view to the possible introduction of this method into the industry.

Downloads

Metrics

References

Drobosyuk V.M. Tekhnologiya izgotovleniya bumagi aerodinamicheskim sposobom. [Technology of paper making by aerodynamic method]. St. Petersburg, 2011, 56 p. (in Russ.).

Schrinner T., Gailat T., Grossmann H., Malinovskaya G. Professional Papermaking, 2016, no. 2, pp. 36–42.

Schrinner T., Gailat T., Grossmann H. Dry defibration – A waterless preparation process for diffi-cult-to-recycle paper and board products // TAPPI PaperCon. 2015.

Schrinner T., Gailat T., Heinemann S., Lundberg M. Selected pulp properties after dry defibration of several paper products // PTS Pulp Symposium Proceedings. München, 2015.

Midukov N.P., Yefremkina P.A., Malinovskaya G.K., Kurov V.S., Smolin A.S. Khimicheskiye volokna, 2017, no. 1, pp. 22–26. (in Russ.).

Midukov N.P., Yefremkina P.A., Malinovskaya G.K., Kurov V.S., Smolin A.S. Sovremennyye zadachi promysh-lennykh tekhnologiy v teploenergeticheskom i lesopromyshlennom kompleksakh: materialy nauchno-prakticheskoy kon-ferentsii studentov i aspirantov. [Modern problems of industrial technologies in heat and power engineering and timber industry complexes: materials of the scientific-practical conference of students and post-graduate students]. St. Petersburg, 2016, pp. 4–6. (in Russ.).

Smolin A.S., Askel'rod G.Z. Formovaniye bumagi i kartona. [Forming paper and cardboard]. Moscow, 1984, 120 p. (in Russ.).

Akim E.L. Osnovy khimii i tekhnologii obrabotki i pererabotki bumagi i kartona. [Fundamentals of chemistry and tech-nology of processing and processing of paper and paperboard]. Moscow, 1979, 229 p. (in Russ.).

Rogovin Z.A. Khimiya tsellyulozy. [Chemistry of cellulose]. Moscow, 1972, 520 p. (in Russ.).

Osovskaya I.I., Boykova V.S. Khimiya rastitel'nogo syr'ya, 2015, no. 1, pp. 175–180. (in Russ.).

Boykova V.S., Osovskaya I.I. Izvestiya vuzov. Khimiya i khimicheskaya tekhnologiya, 2015, no. 6, pp. 74–78. (in Russ.).

Hubbe M.A., Venditti R.A., Rojas O.J. BioResources, 2007, vol. 2, no. 4, pp. 739–788.

Gauze A.A., Goncharov, V.N. Kugushev I.D. Oborudovaniye dlya podgotovki bumazhnoy massy. [Equipment for preparation of pulp]. Moscow, 1992, 352 p. (in Russ.).

Midukov N.P., Kurov V.S., Nikiforov A.O. Izvestiya vuzov. Lesnoy zhurnal, 2008, no. 4, pp. 116–119. (in Russ.).

ISO 5263-1. "Pulps – Laboratory wet disintegration – Part 1" International Organization of Standardization, Geneva, Switzerland. 2004.

ISO 1924-2. "Paper and board – Determination of tensile properties – Part 2: Constant rate of elongation method". In-ternational Organization of Standardization, Geneva, Switzerland. 1994.

ISO 2758. "Determination of bursting strength". International Organization of Standardization, Geneva, Switzerland. 2001.

ISO 22 754. "Specifies a method for the determination of the effective residual ink concentration (ERIC number) by in-frared reflectance measurement". International Organization of Standardization, Geneva, Switzerland. 2008.

ISO 5269-2. "Pulps – Preparation of laboratory sheets for physical testing – Part 2: Rapid-Köthen method". Internation-al Organization of Standardization, Geneva, Switzerland. 2004.

Midukov N.P., Smolin A.S., Kurov V.S., Schrinner T., Grossmann H. Materialien zum wissenschaftlichen Seminar der Stipendiaten der Programme "Michail Lomonosov" und "Immanuel Kant III" 2012/2013. Moscow, 2013, Pp. 53–56.

Midukov N.P., Schrinner T., Grossmann H., Smolin A.S., Kurov V.S. BioResources, 2015, vol. 10, no. 1, pp. 1747–1756.

Midukov N.P., Kurov V.S., Smolin A.S. Proizvodstvo mnogosloynogo test-laynera s belym sloyem. [Production of a multilayer test liner with a white layer]. St. Petersburg, 2018, 208 p. (in Russ.).

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.