THE INFLUENCE OF LOW-TEMPERATURE PROCESSING OF CELLULOSE ON HEATS OF HYDRATION AND STRUCTURE CELLULOSE

UDC 676.023.1

Abstract

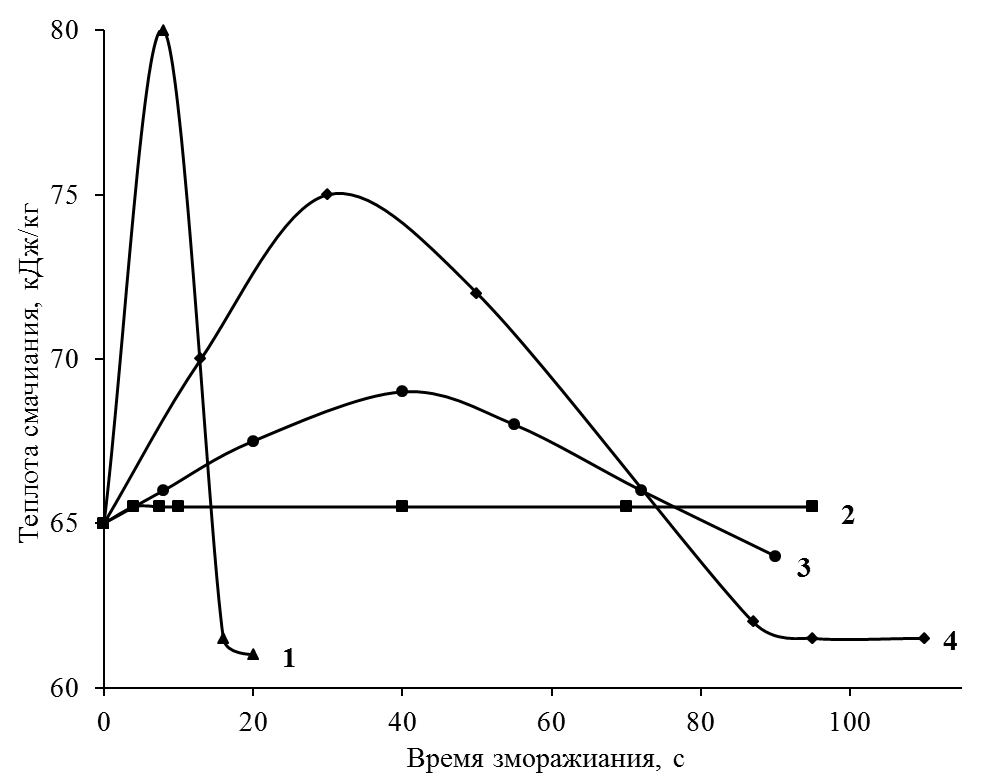

The urgency of the problem of modification of cellulose is dictated by the need to create the latest environmentally friendly technologies for processing cellulose using physical methods of exposure. The complex structure of crystalline and disordered zones, the presence of energetically-unequal system of hydrogen bonds largely determines the sorption, hydrophilic and paper-forming properties of cellulose composites. The method is developed of low-temperature processing of cellulose to create promising environmentally friendly technologies, in particular, for the production of fluff pulp and paper of low mechanical strength with high absorbency. The study of the freezing process of wet cellulose characterizes the behavior of cellulose as a high-molecular polymer with a mobile, plastic structure, easily changed under the influence of various factors. The dependence of the conditions of low-temperature treatment of cellulose on the absorption, hydrophilicity and structure of cellulose fiber is established from the standpoint of the thermodynamic method. Optimum conditions are revealed conditions of freezing wet cellulosic fibers to improve the hydrophilicity and ability formation of links of cellulose. The minimum water content under different conditions of low-temperature treatment of cellulose for the formation of water clusters and ice formation was established. The results of the density measurements by the gradient column method and the sorption of the direct green trisazo dye are consistent with the regularities found in the measurement of the enthalpy of wetting and sorption isotherms.

Downloads

Metrics

References

Smolin A.S. Tekhnologiya tsellyulozno-bumazhnogo proizvodstva. Proizvodstvo bumagi i kartona. Ch. 1. Tekhno-logiya proizvodstva i obrabotki bumagi i kartona. [Pulp and paper technology. Paper and paperboard manufacturing. Part 1. Technology of production and processing of paper and cardboard]. St. Petersburg, 2005, vol. 2, 423 p. (in Russ.).

Klenkova N.I. Zhurnal prikladnoy khimii, 1954, vol. 27, no. 4, pp. 433–437. (in Russ.).

Flyate D.M., Grunin Yu.B. Zhurnal prikladnoy khimii, 1974, vol. 47, no. 12, pp. 2739–2741. (in Russ.).

Reyzin'sh R.E., Laka M.G. Khimiya drevesiny, 1980, no. 5, pp. 16–21. (in Russ.).

Osovskaya I. Cellucon-93, Lund, 1993.

Osovskaya I.I., Baykova V.S., Novoselov N.P. Sbornik dokladov XV Mezhdunarodnoy konferentsii po termi-cheskomu analizu i kalorimetrii v Rossii (RTAS-2016). [Collection of reports of the XV International Conference on Thermal Analysis and Calorimetry in Russia (RTAC-2016)]. St. Petersburg, 2016, vol. 1, pp. 499–502. (in Russ.).

Grebennikov S.F., Aitova A.N., Abramova Ye.S. Khimicheskiye volokna, 2018, no. 3, pp. 41–47. (in Russ.).

Ur'yash V.F., Gruzdeva A.Ye. Termodinamika biologicheski aktivnykh veshchestv. [Thermodynamics of biologically active substances]. Saarbrücken, 2017, 684 p. (in Russ.).

Larina V.N., Ur'yash V.F., Kokurina N.Yu., Novoselova N.V. Vestnik Kazanskogo gosudarstvennogo tekhnolog-icheskogo universiteta, 2010, no. 1, pp. 168–171. (in Russ.).

Osovskaya I.I., Baikova V.S., Avakumova A.V. Fibre Chemistry, 2015, vol. 47, no. 3, pp. 161–165.

Osovskaya I.I., Baykova V.S., Poltoratskiy G.M. Khimiya rastitel'nogo syr'ya, 2015, no. 1, pp. 175–180. (in Russ.).

Obolenskaya A.V., Yel'nitskaya Z.P., Leonovich A.A. Laboratornyye raboty po khimii drevesiny i tsellyulozy. [Labora-tory work on the chemistry of wood and cellulose]. Moscow, 1991, 512 p. (in Russ.).

Mel'nikov B.N., Vinogradova G.I. Primeneniye krasiteley. [The use of dyes]. Moscow, 1986, 240 p. (in Russ.).

Ioelovich M. SITA, 2011, vol. 13, no. 1, pp. 35–44.

Malm E., Bulone V., Wickholm K., Larsson P.T., Iversen T. Carbohydrate Research, 2010, vol. 345, pp. 97–100.

Papkov S.P., Faynberg E.Z. Vzaimodeystviye tsellyulozy i tsellyuloznykh materialov s vodoy. [The interaction of cellu-lose and cellulosic materials with water]. Moscow, 1976, 231 p. (in Russ.).

Grunina N.G., Vinokurova R.I. Vestnik MarGTU. Les. Ekologiya. Prirodopol'zovaniye, 2007, no. 1, pp. 52–54. (in Russ.).

Grunin Yu.B., Grunin L.Yu., Talantsev V.I., Safin R.G., Prosvirnikov D.B. Vestnik Kazanskogo tekhnologicheskogo universiteta, 2014, vol. 17, no. 1, pp. 46–48. (in Russ.).

Akim E.L., Smolin A.S. Khimicheskiye volokna, 2018, no. 4, pp. 81–89. (in Russ.).

Copyright (c) 2019 Khimiya Rastitel'nogo Syr'ya (Chemistry of plant raw material)

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.