OPTIMIZATION OF PRODUCTION CONDITIONS OF AMORPHOUS CELLULOSE WITH A HIGH ENZYMATIC HYDROLYZABILITY

UDC 547.458.8+577.152

Abstract

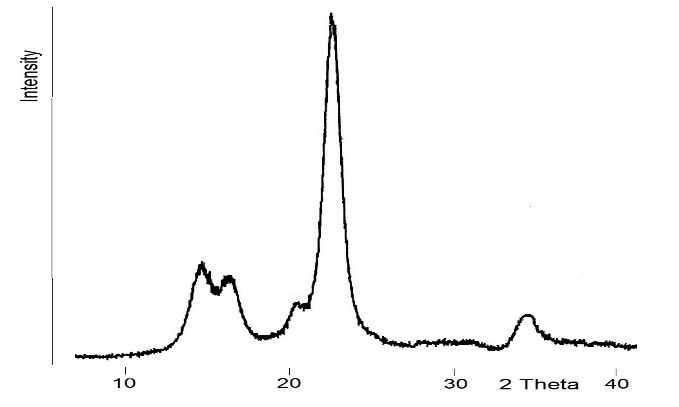

In this paper, a method for producing amorphous cellulose (AC) was studied by treatment of initial cellulosic materials (MCC and mixed paper waste paper) with a cold solvent, containing 7% NaOH and 12% urea, at different solvent to cellulose (R) ratios, ml/g. Using X-ray diffraction, it was found that after treatment of MCC with the solvent at R = 3, the crystalline modification (CM) of CI of the initial cellulose is converted to CM CII, having a low crystallinity degree. In the case, where the initial cellulose is treated with the solvent at R ≥ 5, a completely amorphous cellulose (AC) is formed. Due to its high hydrolyzability, the AC with concentration of 50 g/L is converted into glucose almost completely within 48 hours under the action of the CTec-3 enzyme preparation at a dose of 30 mg/g dry substrate. The obtained AC sample can be used as an amorphous standard in the study of enzymatic hydrolysis of various types of cellulose and lignocellulose. It was found that the most beneficial enzymatic saccharification of AC is carried out at increased concentration of the cellulosic substrate, 150 g/L. Due to the high cost of MCC, it is preferable to use low-cost cellulosic raw material, such as mixed waste paper, for the industrial production of AC and glucose.

Downloads

Metrics

References

Walseth C.S. TAPPI, 1952, vol. 35, pp. 228–233.

Zhou Sh., Ingram L.O. Biotechnology Letters, 2001, vol. 23, pp. 1455–1462.

Zhang Y.H.P., Cui J., Lynd L.R., Kuang L.R. Biomacromolecules, 2006, vol. 7, pp. 644–648.

Zhang Y.H.P., Ding S.Y., Mielenz J.R., et al. Biotechnol. Bioeng., 2007, vol. 97, pp. 214–223.

Anantharam P.D., Sasidhar V., Constange A.S. Biotechnol. Bioeng., 2006, vol. 95, pp. 904–910.

Roseneau T., Potthast A., Sixta H., Kosma P. Prog. Polym. Sci., 2001, vol. 26, pp. 1763–1837.

Schroder L.R., Gentile V.M, Attala R.H. Non-degradative preparation of amorphous cellulose. IPC technical paper series. No 152. Appleton: The Institute of Paper Chemistry, 1985, 14 р.

Ciolacu D., Ciolacu F., Popa V.I. Cellulose Chem. Technol., 2011, vol. 45, pp. 13–21.

Zhang Ch., Liu R., Xiang J., et al. J. Phys. Chem. B, 2014, vol. 118, pp. 9507–9514.

Egal M., Budtova T., Navard P. Cellulose, 2008, vol. 15, pp. 361–370.

Luo X., Liu S., Zhou J., Zhang L. J. Mater. Chem., 2009, vol. 19, pp. 3538–3545.

Duchemin B., Le Corre D., Leray N., et al. Cellulose, 2015, vol. 23, pp. 593–609.

Ioelovich M., Leykin A., Figovsky O. Bioresources, 2010, vol. 5, pp. 1393–1407.

Hall M., Bansal P., Lee J., et al. FEBS Journal, 2010, vol. 277, pp. 1571–1582.

Ioelovich M., Morag E. Bioresources, 2011, vol. 6, pp. 2818–2834.

Ioelovich M., Morag E. Bioresources, 2012, vol. 7, pp. 4672–4682.

Kang A., Lee T.S. Bioengineering, 2015, vol. 2, pp. 184–203.

Muratova E.I., Zyuzina O.V., Shunayeva O.B. Biotekhnologiya organicheskikh kislot i belkovykh preparatov. [Biotech-nology of organic acids and protein preparations]. Tambov, 2007, 80 p. (in Russ.).

Bekatorou A., Psarianos C., Koutinas A.A. Food Technol. Biotechnol., 2006, vol. 44, pp. 407–415.

Anderson C., Longton J., Maddix C., et al. Single-Cell Protein, MIT Press. Cambridge, 1975, pp. 314–329.

Junker B., Mann Z., Seeley A., et al. Appl. Biochem. Biotechnol., 2002, vol. 97, pp. 63–78.

Molina-Ramírez C., Castro M., Osorio M., et al. Materials, 2017, vol. 10, pp. 1–13.

Reddy C.S.K., Ghai R., Kalia V.C. Bioresource Technology, 2003, vol. 87, pp. 137–146.

Copyright (c) 2020 Khimiia rastitel'nogo syr'ia (Chemistry of plant raw material)

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.