FLUID FLOW BODIES FOR THE PULP AND PAPER INDUSTRY

UDC 676.1+681.121.4

Abstract

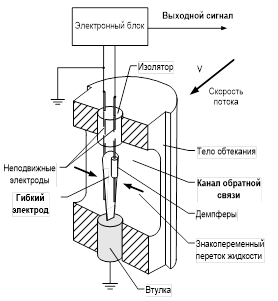

The question of the use of vortex flowmeters with different versions of the flow body (TO) under operating conditions on the technological lines of pulp and paper production is considered.

It is shown that when using different TO in vortex flowmeters, an error occurs in the working range of speeds (flow rates). The observed error arises due to a change in the Strouhal number (Sh) and is associated with the measurement method. In this case, the Strouhal number begins to depend not only on the TO used as a vortex generator, but also on the flow velocity and the concentration of the fibrous suspension. As the main comparative factor for the investigated TOs, the force action on the sensitive element (flexible electrode) located inside the TO was taken.

The study was carried out in several stages using numerical modeling and experimental design method. According to the results of a numerical study, the dependence of the Strouhal number (Sh) on the flow rate (V) and the concentration of the suspension (c) is presented.

In a comparative analysis of the deviation of the Strouhal number from the average values, it was revealed that MOT No. 1 has a minimal effect on the concentration of the suspension in the working range of flow rates (± 0.5%). This circumstance makes it possible to verify and test flow meters with such maintenance in conventional pouring installations.

The analysis of the maintenance with respect to the signal-to-noise ratio shows that the purest signal is generated by the cylindrical maintenance (maintenance No. 3), and maintenance No. 2 and No. 1 have noticeably large noise. The differences are explained by the absence on the surface of a cylindrical TO of extra protrusions, faces, which leads to a smoother flow of a suspension around its surface, as well as to a decrease in internal spurious noise.

Downloads

Metrics

References

Lur'ye M.S., Lur'ye O.M. Tsellyuloza. Bumaga. Karton, 2009, no. 10, pp. 62–66. (in Russ.).

Lur'ye M.S., Lur'ye O.M., Frolov A.S. Izvestiya Sankt-Peterburgskoy lesotekhnicheskoy akademii, 2019, no. 227, pp. 271–292. DOI: 10.21266/2079-4304.2019.227.271-292. (in Russ.).

Alashkevich Yu.D., Lur'ye M.S., Lur'ye O.M., Frolov A.S. Khimiya rastitel'nogo syr'ya, 2018, no. 4, pp. 273–279. DOI: 258/jcprm.2018044036. (in Russ.).

Lur'ye M.S., Lur'ye O.M. Datchiki i sistemy, 2008, no. 10, pp. 21–23. (in Russ.).

Lur'ye M.S. Khimiya rastitel'nogo syr'ya, 2010, no. 4, pp. 173–176. (in Russ.).

Vershinin V.Ye., Polkovnikov F.I. Avtomatizatsiya v promyshlennosti, 2016, no. 1, pp. 44–47. (in Russ.).

Shmelev V.Ye. Femlab 2.3. Rukovodstvo pol'zovatelya. [Femlab 2.3. User guide]. Moscow, 1999, 442 p. (in Russ.).

Turner J.T., Popiel C.O., Robinson D.I. Flow Measurement and Instrumentation, 1993, no. 4, pp. 249–259.

El Wahed A.K., Johnson M.W., Sproston J.L. Flow Measurement and Instrumentation, 1993, vol. 4, no. 4, pp. 233–240.

Pankanin G.L., Chmielewski R., Berliński J. Metrology and Measurement Systems, 2005, vol. XII, no. 4, pp. 413–425.

Bogdanov V.D., Konyukhov A.V., Krivonogov A.A., Safonov Ye.V., Dorokhov V.A. Datchiki i sistemy, 2012, no. 8(159), pp. 40–43. (in Russ.).

Alashkevich Yu.D., Reshetova N.S., Nevzorov A.I., Baranovskiy V.P. Gidrodinamicheskiye yavleniya pri bezno-zhevoy obrabotke voloknistykh materialov. [Hydrodynamic Phenomena during Bladeless Treatment of Fibrous Materi-als]. Krasnoyarsk, 2004, 80 p. (in Russ.).

Alashkevich Yu.D., Lur'ye M.S., Lur'ye O.M., Frolov A.S. Khimiya rastitel'nogo syr'ya, 2019, no. 3, pp. 273–279. DOI: 10.14258/jcprm.2019035113. (in Russ.).

Johnson W., Sproston J.L., Wahed A.E. Flow Measurement Instruments, 1993, vol. 4 (4), pp. 233–240.

Hebrard P., Malard L., Strzelecki A. Flow Measurement Instruments, 1992, vol. 3, pp. 173–186.

Cambier P., Vandermar S., Lavante E.V., Banaszak U., Krisch H., Tournillon S. XIX IMEKO World Congress Funda-mental and Applied Metrology, 2009, vol. 1, pp. 15–18.

Yerofeyeva A.A., Reshetova N.S., Kovalev V.I., Alashkevich Yu.D. Khimiya rastitel'nogo syr'ya, 2010, no. 4, pp. 177–182. (in Russ.).

Pen R.Z. Statisticheskiye metody modelirovaniya i optimizatsii protsessov tsellyulozno-bumazhnogo proizvodstva. [Sta-tistical methods for modeling and optimization of pulp and paper production processes]. Krasnoyarsk, 1982, 192 p. (in Russ.).

Zorich V.A. Matematicheskiy analiz. [Mathematical analysis]. Moscow, 1984, 544 p. (in Russ.).

Kholodnov V.A. i dr. Matematicheskoye modelirovaniye i optimizatsiya khimiko-tekhnologicheskikh protsessov: prak-ticheskoye rukovodstvo. [Mathematical modeling and optimization of chemical-technological processes: a practical guide]. St.-Petersburg, 2003, 480 p. (in Russ.).

Loytsyanskiy L.G. Mekhanika zhidkosti i gaza: ucheb. dlya vuzov. [Mechanics of liquid and gas: textbook. for universi-ties]. Moscow, 2003, 840 p. (in Russ.).

Copyright (c) 2020 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.