RESEARCH OF PHYSICAL AND MECHANICAL PROPERTIES OF WOOD-FIBER MATERIALS

UDC 676.1.054.1

Abstract

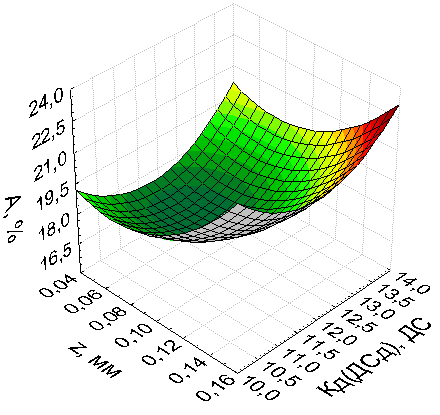

This paper presents the results of experimental studies of the physical and mechanical properties of wood-fiber boards of the wet production method when regulating the design and technological parameters of the grinding process. This allowed us to determine the influence of the working clearance between the grinding discs and the concentration of fibre mass with the subject to of quality change wood fiber after defibrator using the developed construction of the disc fibrillation action on the physico-mechanical properties of boards. As a result of the experiment, regression models were obtained that adequately describe the studied grinding process and allow predicting the values of physical and mechanical properties of the finished product depending on the established parameters process.

A comparative analysis of the size and quality characteristics of the fiber semi-finished product and its fractional composition when using a developed construction the disc of refiner fibrillation action and a traditional design used in industry is carried out. The preferential efficiency of the grinding process under the fibrillating effect the disc of refiner in comparison with the traditional construction disc of refiner is established. As a result, there is a significant improvement in the quality indicators of the fiber semi-finished product and its composition due to the formation and predominance in the total mass of long and thin, respectively, flexible fibrillated fibers with high tile-forming properties, which allows to increase the strength properties of the product (by 20–25%), without using binding resins.

Downloads

Metrics

References

Zhang D., Zhang A., Xue L. Wood Sci Technol., 2015, vol. 49, pp. 661–679. DOI: 10.1007/s00226-015-0728-6.

Camlibel O., Akgul M. Wood Research, 2020, vol. 65 (2), pp. 231–244.

GOST 4598-2018. Plity drevesnovoloknistyye mokrogo sposoba proizvodstva. Tekhnicheskiye usloviya. [GOST 4598-2018. Wet fiberboards. Technical conditions]. Moscow, 2018, 15 p. (in Russ.).

Vititnev A.Yu. Sovershenstvovanie processa razmola voloknistyh polufabrikatov v proizvodstve drevesnovoloknistyh plit: dis. ... kand. tekhn. nauk. [Improving the process of grinding fiber semi-finished products in the production of wood-fiber boards: dissertation of the candidate of technical sciences]. Krasnoyarsk, 2019, 152 p. (in Russ).

Tikhonova E., Irle M., Lecourt M. Holzforschung, 2015, vol. 69 (5), pp. 627–632. DOI: 10.1515/hf-2014-0049.

Schubert M., Luković M., Christen H. Wood Sci Technol., 2020, vol. 54, pp. 703–713. DOI: 10.1007/s00226-020-01184-3

Zyryanov M.A., Chistova N.G. Izvestiya VUZov. Lesnoy zhurnal, 2013, no. 6. Pp. 115–119. (in Russ).

Chistova N. G. Pererabotka drevesnyh othodov v tekhnologicheskom processe polucheniya drevesnovoloknistyh plit: dis. ... dokt. tekhn. nauk. [Processing of wood waste in the technological process of obtaining wood-fiber boards: dis-sertation of doctor of technical sciences]. Krasnoyarsk, 2010, 415 p. (in Russ).

Shi S.Q. Wood Sci Technol., 2007, vol. 41, pp. 645–658. DOI: 10.1007/s00226-006-0123-4.

GOST 10633-2018. Plity drevesno-struzhechnyye i drevesno-voloknistyye. Obshchiye pravila podgotovki i pro-vedeniya fiziko-mekhanicheskikh ispytaniy. [GOST 10633-2018. Chipboards and fibreboards. General rules for the preparation and conduct of physical and mechanical tests]. Moscow, 2018, 14 p. (in Russ.).

Laskeyev P.Kh. Proizvodstvo drevesnoy massy. [Wood pulp production]. Moscow, 1967, 581 p. (in Russ.).

Alashkevich Yu.D., Kovalev V.I., Kozhuhov V.A. Izvestiya VUZov. Lesnoy zhurnal, 2014, no. 2. Pp. 94–100. (in Russ).

Riegler M., Spangl B., Weigl M., Wimmer R., Muller U. Wood Sci Technol., 2013, vol. 47, pp. 1243–1259.

Nabiyeva A.A. Otsenka vliyaniya i sovershenstvovaniya tekhnologicheskikh parametrov nozhevykh razmalyvayush-chikh mashin: dis. ... kand. tekhn. nauk. [Assessment of the influence and improvement of technological parameters of knife grinding machines: dis. ... Cand. tech. sciences]. Krasnoyarsk, 2004, 156 p. (in Russ.).

Vikharev S. IOP Conf. Series: Earth and Environmental Science, 2019, vol. 316, 012080.

Bordin R., Roux J.-C., Bloch J.-F. Appita Journal, 2008, vol. 61, pp. 71–77.

Ferritsius O., Ferritsius R., Rundlof M. Nord. Pulp Pap. Res. J., 2018, vol. 33(3), pp. 468–481.

Li B., Li H.M., Zha Q.Q., Bandekar R., Alsaggaf A., Ni Y.H. BioResources, 2011, vol. 6(3), pp. 3569–3584.

Smith S. Die rationelle Theorie das Ganzzeughollandar. Teil I. Berlin: Otto Ernst Verlag, 1922, 105 p.

Mcdonald D., Tchepel M., Ouellet D., Wild P., Jeffrey D., Provan J. J – FOR, 2014, vol. 4(5), pp. 23–30.

Pizhurin A.A. Osnovy nauchnykh issledovaniy. [Fundamentals of Scientific Research]. Moscow, 2005, 305 p. (in Russ.).

Borovikov V.P., Borovikov I.P. STATISTICA. Statisticheskiy analiz i obrabotka dannykh v srede Windows. [STATIS-TICA. Statistical analysis and data processing in Windows environment]. Moscow, 1998, 605 p. (in Russ.).

Copyright (c) 2020 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.