PREPARATION OF WOOD FIBER SEMI-FINISHED PRODUCTS IN KNIFE MACHINES OF VARIOUS MODIFICA-TION

UDC 676.154.3

Abstract

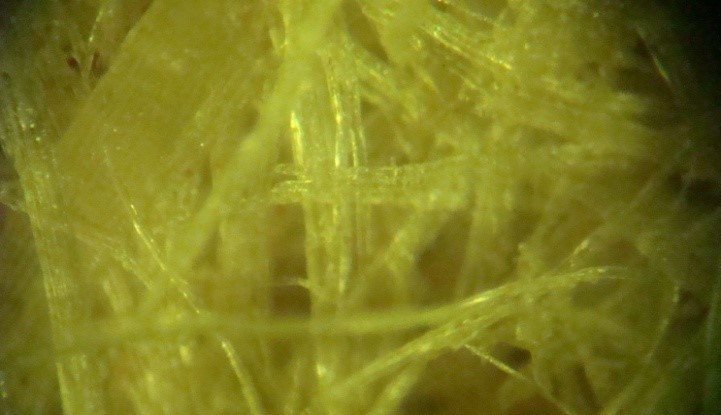

In this paper, we consider the results of a study of the influence of the design and technological parameters of grinding machines of various modifications on the quality of wood pulp.

According to the results of processing multifactor experiments implemented according to the second-order B-plan, a mathematical description was obtained of the dependence of the degree of grinding of pulp on the gap between the grinding disks, wear of the segments, the rotational speed of the lower screw and the concentration of pulp. The obtained regression models are adequate to the process and can be applied in practice for predicting the qualitative characteristics of wood pulp depending on the parameters of the grinding process.

Analyzing the obtained experimental data, it can be noted that such factors as the state of the surfaces of grinding disks, the gap between them and the concentration of wood fiber have the greatest influence on the degree of grinding of the mass. Evaluation of graphical dependencies allows you to determine the extent to which you can vary the operating and design parameters of the grinding process to obtain wood fiber with the required grinding quality.

Downloads

Metrics

References

Chistova N.G. Pererabotka drevesnykh otkhodov v tekhnologicheskom protsesse polucheniya drevesnovoloknistykh plit: disssertatsiya doktora tekhnicheskikh nauk. [Processing of wood waste in the technological process of obtaining fiber-board: dissertation of a doctor of technical sciences]. Krasnoyarsk, 2010, 415 p. (in Russ.).

Zhang D., Zhang A., Xue L. Wood Sci Technol., 2015, vol. 49, pp. 661–679, DOI: 10.1007/s00226-015-0728-6.

Matygulina V.N. Podgotovka drevesnovoloknistykh polufabrikatov v proizvodstve drevesnovoloknistykh plit sukhim sposobom: dissertatsiya kandidat tekhnicheskikh nauk. [Preparation of semi-finished wood-fiber products in the pro-duction of wood-fiber boards by dry method: Ph.D. thesis]. Krasnoyarsk, 2007, 183 p. (in Russ.).

Chistova, N.G., Matygulina V.N. Vestnik KrasGAU, 2007, no. 4, pp. 139–143. (in Russ.).

Chistova N.G. Khimiya rastitel'nogo syr'ya, 200, no. 2, pp. 141–144. (in Russ.).

Benthien J., Heldner S., Ohlmeyer M. European Journal of Wood and Wood Products, 2017, pp. 215–232.

Shi S.Q. Wood Sci Technol., 2007, vol. 41, pp. 645–658, DOI:10.1007/s00226-006-0123-4

Benthien J., Bähnisch C., Heldner S., Ohlmeyer M. Wood and fiber science, 2014, vol. 46(2), pp. 175–185.

Ihnát V., Lübke H., Russ A., BorůvkaV. Wood research. 2017, vol. 62(1), pp. 45–56.

Morozov I.M., Chistova N.G. Khimiya rastitel'nogo syr'ya, 2015, no. 3, pp. 185–191. DOI: 10.14258/jcprm.201503543.

Chistova N.G., Morozov I.M, Yakimov V.A, Alashkevich YU.D., Zyryanov M.A. Khimiya rastitel'nogo syr'ya, 2015, no. 4, pp. 119–124. DOI: 10.14258/jcprm.201504852.

Ferritsius O., Ferritsius R., Rundlof M. Nord. Pulp Pap. Res. J., 2018, vol. 33(3), pp. 468–481.

Mcdonald D., Tchepel M., Ouellet D., Wild P., Jeffrey D., Provan J. J – FOR., 2014, vol. 4(5), pp 23-30.

Riegler M., Spangl B., Weigl M., Wimmer R., Muller U. Wood Sci Technol., 2013, vol. 47, pp. 1243–1259.

Borovikov V.P., Borovikov I.P. STATISTICA. Statisticheskiy analiz i obrabotka dannykh v srede Windows. [STATIS-TICA. Statistical analysis and data processing in Windows environment]. Moscow, 1998, 605 p. (in Russ.).

Pizhurin A.A. Osnovy nauchnykh issledovaniy. [Fundamentals of Scientific Research]. Moscow, 2005, 305 p. (in Russ.).

Laskeyev P.KH. Proizvodstvo drevesnoy massy. [Wood pulp production]. Moscow, 1967, 581 p. (in Russ.).

Patent 2483150 (RU). 2012.

Patent 143379U1 (RU). 2014.

Patent 2556596 (RU). 2015.

Patent 156722U1 (RU). 2015.

Patent 160973U1 (RU). 2015.

Copyright (c) 2020 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.