USE OF ULTRASOUND FOR EXTRACTION OF BIOLOGICALLY ACTIVE SUBSTANCES FROM TAMARIX HISPI-DA WILLD.

UDC 547. 972

Abstract

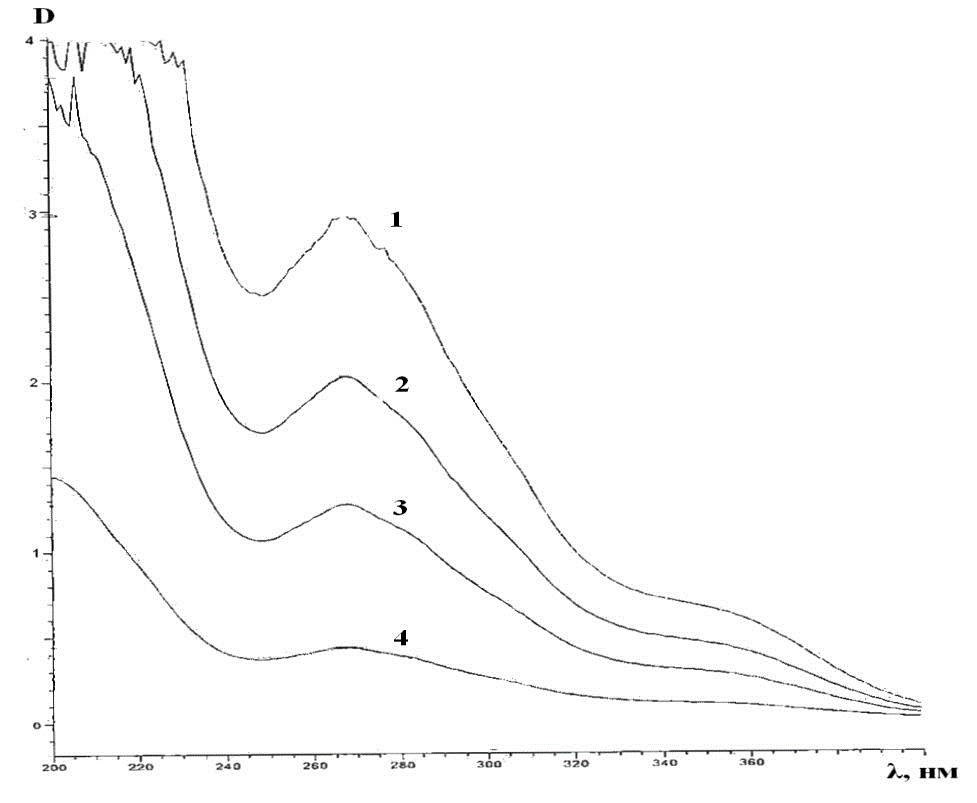

The extractions of biologically active substances from aerial part of Tamarix hispida Willd. over ultrasound have been studied. The results showed that the output of extractive substances using ultrasound was increased to 37.34% under the following conditions: 10% ethyl alcohol in a raw-extractant ratio (1 : 6) for 25 minutes at a 20–25 °С temperature and an ultrasound frequency of 35 kHz. The extraction was compared with maceration by yield and chemical composition. As a result of optimization, the output of components from the raw material is increased by 3–4 times at ultrasound frequency from 20 to 35 kHz and extraction time is significantly reduced from 48 hours to 30 minutes. It was found that the major substances were hydrolyzable tannins, the content of which are 10% (ultrasonic extraction) and 8% (maceration), respectively. Using UV-spectrometry, it was confirmed that the appearance of a characteristic maximum in the spectrum of the substance to be analyzed corresponds to the area of absorption of gallic acid and its derivatives, which indicates the content of these in the structure of hydrolyzable tannins. The substance shown significant antidiabetic activity (in vitro) at IC 50 = 3.94±0.14 μg/ml.

Downloads

Metrics

References

Ikhsanov Y.S., Abilov Zh.A., Choudhary M.I., Sultanova N.A. Vestnik Karagandinskogo Universiteta, 2018, vol. 89, no. 1, pp. 8-13.

Ikhsanov Y.S., Abilov Zh.A., Sultanova N.A., Choudhary M.I. Izv. Vyssh. Uchebn. Zaved. Khim. Khim. Tekhnol., 2018, vol. 61, no. 6, pp. 83–87. DOI: 10.6060/tcct.20186106.5706. (in Russ.)

Sultanova N.A. Khimicheskiy zhurnal Kazakhstana, 2009, vol. 27, no. 4. pp. 102-105. (in Russ.).

Sultanova N.A. Izv. NTO «Kakhak», 2009, vol. 24, no. 2, pp. 39–42. (in Russ.).

Sultanova N. А., Makhmoor T., Yasin A., Abilov Zh.A., Omurkamzinova V.B, Atta-ur-Rahman, Choudhary M.I. Planta Medica, 2004, vol. 70, no. 1, pp. 65–67. DOI: 0009-3130/04/4002-0192.

Belokurov S.S., Narkevich I.A., Flisyuk E.V., Kaukhova I.E., Aroyan M.V. Khimiko-farmatsevticheskiy zhurnal, 2019, vol. 56, no. 6, pp. 45–50. DOI: 10.30906/0023-1134-2019-53-6-48-53. (in Russ.).

Belokurov S.S., Flisyuk E.V., Narkevich I.A., Luzhanin V.G., Shilov S.V., Novikova R.O. Razrabotka i registratsiya lekarstvennykh sredstv, 2019, vol. 8, no.3, pp. 49–55. DOI: 10.33380/2305-2066-2019-8-3-49-55. (in Russ.).

Vilkhu K., Mawson R., Simons L., Bates D. Innovative Food Science and Emerging Technologies, 2008, vol. 9, no. 2, pp. 161-169. DOI: 10.1016/j.ifset.2007.04.014.

Patist A., Bates D. Innovative Food Science and Emerging Technologies, 2008, vol.9, no. 2, pp. 147–154. DOI: 10.1016/j.ifset.2007.07.004.

Zhang H.-F., Yang T.-Sh., Li Z.-Zh., Wang Y. Ult. Sonochemistry, 2008, vol. 15, no. 4, pp. 376-385. DOI: 10.1016/j.ultsonch.2007.09.002.

Valeeva A.R., Makarova N.V., Valiulina D.F. Proceedings of Universities. Applied Chemistry and Biotechnology, 2019, vol. 9, no. 2, pp. 239–249. DOI: 10.21285/2227-2925-2019-9-2-239-249.

Apaeva A.V., Yamansarova E.T., Kukovinets O.S., Zvorigina O. B. Vestnik Bashkirskogo universiteta, 2016, vol. 21, no. 1, pp. 69–72. (in Russ.).

Wang S., Shi Y., Zhang G., Meng Y., Zhang N., Madhujith T. Food Industry, 2018, vol. 3, no. 3, pp. 33–45. DOI: 10.29141/2500- 1922-2018-3-3-6.

Ameer K., Shahbaz H.M., Kwon J.H. Comprehensive Reviews in Food Science and Food Safety, 2017, vol. 16, no. 2, pp. 295–315. DOI: 10.1111/1541-4337.12253.

Popova O.S., Skrypnik L.N. Uspekhi sovremennogo yestestvoznaniya, 2017, no. 6, pp. 34–38. (in Russ.).

Zou T.-B., Wang M., Gan R.-Y., Ling W.-H. International journal of molecular sciences, 2011, vol. 12, no 5, pp. 3006–3017. DOI: 10.3390/ijms1205300.

Sharma A., Gupta M.N. Ult. Sonochemistry, 2006, no. 6, pp. 529-534. DOI: 10.1016/j.ultsonch.2005.09.008.

Patel D.K., Prasad S.K., Kumar R., Hemalatha S. Asian Pacific Journal of Tropical Biomedicine, 2012, vol. 2, no. 4, pp. 320–330. DOI: 10.1016/S2221-1691(12)60032-X.

Gosudarstvennaya farmakopeya Respubliki Kazakhstan. [The State Pharmacopoeia of Kazakhstan]. Almaty, 2008, vol. 1, 592 p. (in Russ.).

Bozorov K., Ma H.-R., Zhao J.-Y., Zhao H.-Q., Chen H., Bobakulov K., Xin X.-L., Elmuradov B., Shakhidoyatov K., Aisa H.A. Eur. J. Med. Chem., 2014, vol. 84, pp. 739–745. DOI: 10.1016/j.ejmech.2014.07.065.

Nawwar M.A., Hussein S.A., Buddrus J. Phytochem., 1994, vol. 35, no 5, pp. 1349–1354.

Gylymkhan N.T., Uryngaliev D.I., Sultanova N.A., Zhumagalieva Sh.N., Abilov Zh.A. Vestnik ENU, 2016, vol. 113, no. 4, pp. 279–283. (in Russ.).

Abdimalik N.Zh., Zhumagalieva Sh.N., Abilov Zh.A., Sultanova N.A. Farmacya Kazakhstana, 2019, no. 10, pp. 29–32. (in Russ.).

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.