PHYSICOCHEMICAL PROPERTIES OF SULPHATE WASTE LIQUOR AFTER SOAP EXTRACTION IN THE PRESENCE OF SURFACTANTS

UDC 676.2

Abstract

During the wood delignification a multicomponent spent liquor (black liquor) is formed. Depending on the type of wood, black liquor is enriched with valuable extractives. The isolation of extractives from processing liquors and their conversion into biologically active substances, tall products is according to development trend of pulp and paper industry. It includes the introduction of scientific based technologies in manufacturing processes with reference to modern environmental protection requirements. Now the extraction efficiency of sulphate soap does not exceed 75–80% whereby the quality of obtained soap is low. Sulphate soap, especially extracted after hardwood cooking, contains a large amount of impurities. This complicates the process of soap treatment into valuable biologically active substances (beta-sitosterol, etc.).

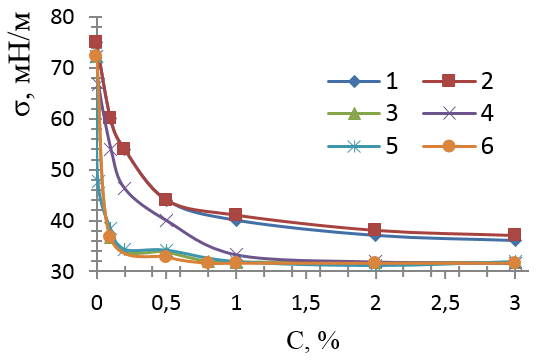

In the present work the addition of demulsifying and coagulating substances into the black liquor is proposed to intensify the hardwood sulphate soap extraction. The chemical colloidal characteristics of the obtained sulphate soap were investigated. Two critical micelle concentration (CMC) were found on the surface tension isotherms. The second critical micelle concentration (CMC2) in the concentration range of 0.9–1.0% CMC2 indicates the restructuring of micelles into a spherocylindrical shape. A comparative qualitative and quantitative analysis of the composition of sulfate soap obtained in industrial conditions and in the presence of selected additives in laboratory was carried out. Surfactants promote the extraction of phytosterol from black liquor obtained from hardwood species cooking. The influence of surfactant addition on the main physical and colloidal chemical characteristics of black liquor before and after isolation of sulphate soap is investigated. A decrease in viscosity and a de foaming of a black liquor solution is observed as a result of the addition of surfactant additives.

Downloads

Metrics

References

Bogomolov B.D., Sapotnitskiy S.A., Sokolov O.M. Pererabotka sul'fatnogo i sul'fitnogo shchelokov. [Processing of sulphate and sulphite liquors]. Moscow, 1989, 360 p. (in Russ.).

Nepenin YU.N. Proizvodstvo sul'fatnoy tsellyulozy. [Sulphate pulp production]. Moscow, 1990, 601 p. (in Russ.).

Lysogorskaya N.P., Dem'yantseva Ye.YU., Klyubin V.V. Kolloidnyy zhurnal, 2002, vol. 64, no. 3, pp. 427–429. DOI: 10.1023/A:1015989330575. (in Russ.).

Wang Z., Shen T., Yang Y., Gao B., Wan Y., Li Y.C., Yao Y., Liu L., Tang Y., Xiea J., Ding F., Chen J. Journal of Cleaner Production, 2020, vol. 243, 118585. DOI: 10.1016/j.jclepro.2019.118585.

Aryan V., Kraft A. Journal of Cleaner Production, 2021, vol. 280, pp. 1–13. DOI: 10.1016/j.jclepro.2020.124616.

Vladimirova T.M., Sokolov O.M., Tret'yakov S.I. Fizikokhimiya lignina: materialy mezhdunarodnoy konferentsii. [Phys-icochemistry of lignin: materials of the international conference]. Arkhangel'sk, 2005, pp. 157–160. (in Russ.).

Feygus E.I., Zmachinskaya N.Ye. Tsellyuloza. Bumaga. Karton (obzor informatsii). [Cellulose. Paper. Cardboard (in-formation overview)]. Moscow, 1990, no. 9, 48 p. (in Russ.).

Filippov B.S. Izvestiya vuzov. Lesnoy zhurnal, 1964, no. 1, pp. 154–158. (in Russ.).

Tsvetkov A.A., Bogdanovich N.I., Selyanina S.B. Tsellyuloza. Bumaga. Karton, 2014, no. 7, pp. 58–61. (in Russ.).

Tsarev G.I., Nekrasova V.B. Lesokhimiya i podsochka (obzor informatsii) [Timber chemistry and tapping (information review)]. Moscow, 1985, no. 3, 40 p. (in Russ.).

Lichutina T.F., Sazhinov A.A. Gidroliznaya i lesokhimicheskaya promyshlennost, 1985, no. 4, pp. 20. (in Russ.).

Koverninskiy I.N., Komarov V.I., Tret'yakov S.I., Bogdanovich N.I., Sokolov O.M., Kutakova N.A., Selyanina L.I. Kompleksnaya khimicheskaya pererabotka drevesiny. [Complex chemical processing of wood]. Arkhangelsk, 2002, 347 p. (in Russ.).

Kovasin K., Tikka P., Laxén T. Pulp and Paper, 2002, vol. 103, issue 6, pp. 30–35.

Rouskova M., Heyberger A., Triska J., Krticka M. Chemical papers, 2011, vol. 65, no. 6, pp. 805‒811. DOI: 10.2478/s11696-011-0077-3.

Ela R.C.A., Spahn L., Safaie N. ACS Sustainable Chem. Eng., 2020, vol. 8, pp. 13997–14005. DOI: 10.1021/acssuschemeng.0c03692.

Aro T., Fatehi P. Separation and Purification Technology, 2016, vol. 175, pp. 469–480. DOI: 10.1016/j.seppur.2016.10.027.

Akimova G.S., Kurzin A.V., Pavlova O.S., Yevdokimov A.N. Khimiya i tekhnologiya komponentov sul'fatnogo myla. [Chemistry and technology of sulfate soap components]. St. Petersburg., 2008, 104 p. (in Russ.).

Tekhnologiya tsellyulozno-bumazhnogo proizvodstva. V 3 t. T. I. Syr'ye i proizvodstvo polufabrikatov. [Technology of pulp and paper production. In 3 vol. Vol. I. Raw materials and production of semi-finished products]. St. Petersburg, 2003, 633 p. (in Russ.).

Rusanov A.I., Shchokin A.K. Mitselloobrazovaniye v rastvorakh poverkhnostno-aktivnykh veshchestv. [Micelle for-mation in surfactant solutions]. St. Petersburg, 2016, 612 p. (in Russ.).

Lara M., Rodriguez-Malaver J., Rojas O.J. International Biodeterioration & Biodegradation, 2003, vol. 52, pp. 167–173. DOI: 10.1016/S0964-8305(03)00055-6.

Nassar M.M., Hassan K.M., Farrag T.E., Abd Elrahman S.A. International Water Technology Journal, 2016, vol. 6, no. 3, pp. 214–220.

Demin V.A. Khimiya i tekhnologiya sul'fatnykh shchelokov. [Chemistry and technology of sulfate liquors]. Syktyvkar, 2013, 127 p. (in Russ.).

Andreuccetti M.T., Leite B.S., d’Angelo J.V.H. O Papel, 2011, vol. 72, no. 12, pp. 52–57.

Sokolov O.M., Tret’yakov S.I. Proceedings of the International Conference "Physical Chemistry of Lignin", Arkhan-gelsk, 2005, pp. 157–160.

Cardoso M., Oliveria E.D., Passos M.L. Fuel, 2009, vol. 88, no. 4, pp. 756‒763.

Adams T. Tappi Journal, 2001, vol. 84, no. 6, pp. 1–18.

Polaa L., Colladoa S., Oulegoa P., Calvob P., Díaza M. Chemical Engineering Journal, 2021, vol. 405, pp. 1–10. DOI: 10.1016/j.cej.2020.126610.

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.