DEVELOPMENT OF THE TECHNOLOGY FOR THE SEPARATION OF THE COMPONENTS FROM GREEN TEA USING THE PREPARATIVE LIQUID CHROMATOGRAPHY BY DESIGN OF PERIODICAL PROCESS

UDC 663.9

Abstract

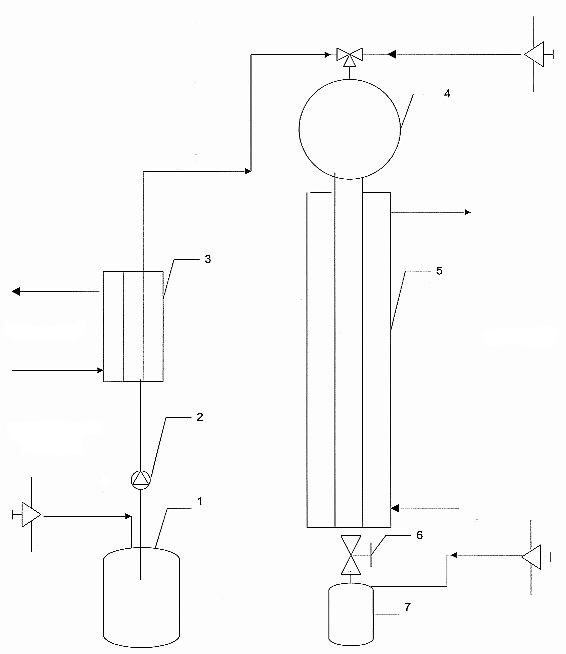

Leaves of the green tea plant camellis sinensis contain up to 36 % polyphenols. Epigallocatechin gallate (EGCG) is the most interesting polyphenols because it exhibits a strong antioxidant effect. Furthermore, it has been demonstrated that EGCG has an antimutagenic and an anticancer effects, an antibacterial effect and a beneficial effect on cholesterol level in blood. Therefore, is needed to isolate EGCG in a pure form in high yield by simple and commercial process. This method for isolation of EGCG contents the following steps: a) selection of macroporous polar resin for the preparative liquid chromatography; b) selection of polar elution solvent; c) determination the temperature and pressure for adsorbtion and desorbtion of the polyphenols of the green tea. Therefore, it was searched the interconnection between yield of EGCG and the range of temperature and amount of eluent. Finally, the process for the separation of Epigallocatechin gallate from green tea extract was developed in the laboratory and EGCG was isolated with the concentration 92% by the yield 43%. Accordingly, the technology of EGCG production based on the preparative liquid chromatography was launched and introduced on the market.

Downloads

Metrics

References

Scholz E., Bertram B. Zeitschrift für Phytotherapie, 1995, vol. 17, pр. 235–250.

Saito S.T., Gosmann G., Pungartnik C., Brendel M. Aktuelle Patente auf Lebensmittel, Ernährung & Landwirtschaft, 2009, vol. 1, pр. 203–215.

Tachibana H. Proceedings of the Japan Academy, 2011, vol. 8, no. 3, pp. 66–80.

Chen D., Wan S.B. Advances in clinical chemistry, 2011, vol. 53, pp. 155–177.

Khan N., Adhami V.M., Mukhtar H. Nutrition and Cancer, 2009, vol. 61, no. 6, pp. 836–841. DOI: 10.1080/01635580903285056.

Tachibana H., Koga K., Fujimura Y., Yamada K. Nature Structural & Molecular Biology, 2004, pp. 380–381. DOI: 10.1038/nsmb743.

Xu H., Becker C.M. Fertility and Sterility, 2011, vol. 96, no. 4, pp. 1021–1028. DOI: 10.1016/j.fertnstert.2011.07.008.

Nihal M., Roelke C.T., Wood G.S. Pharmaceutical Research, 2010, vol. 27(6), pp. 1103–1114.

Xiao X., Yang Z.Q., Shi L.Q., Liu J., Chen W. Zhongguo Zhong yao za zhi = Zhongguo zhongyao zazhi = China journal of Chinese materia medica, 2008, vol. 33, pp. 2678–2682.

Aktas O., Prozorovski T., Smorodchenko A., Savaskan N.E., Lauster R., Kloetzel P.M., Infante-Duarte C., Brocke S., Zipp F. Journal of Immunology, 2004, vol. 173(9), pp. 5794–5800.

Lee K.W., Lee H.J. BioFactors, 2006, vol. 26, no. 2, pp. 105–121.

Widlansky M.E., Hamburg N.M. Journal of the American College of Nutrition, 2007, vol. 26, no. 2, pp. 95–102.

Zhu B.H., Zhan W.H., Li Z.R., Wang Z., He Y.L., Peng J.S., Cai S.R., Ma J.P., Zhang C.H. World journal of gastro-enterology, 2007, vol. 13, no. 8, pp. 1162–1169.

Steinmann J., Buer J., Pietschmann T., Steinmann E. British Journal of Pharmacology, 2013, vol. 168, pp. 1059–1073. DOI: 10.1111/bph.12009.

Russel M., Lilley T.H., Bailey N.A., Falshaw C.P., Haslam E., Magnotalo D., Begley M.J. Journal of the Chemical Society, Chemical Communications, 1986, pp. 105–106.

Min Z., Peigen X. Phytotherapy Research, 1991, vol. 5, p. 239.

Saijo R. Agricultural and Biological Chemistry, 1982, vol. 46, pp. 1969–1970.

Datenblatt. Epigallocatechin gallate bei Sigma-Aldrich. 2017, vol. 27.

Bidlingmeyyer B., Frayd B., Khegnauyer G. i dr. Preparativnaya zhidkostnaya khromatografiya. [Preparative liquid chromatography]. Moscow, 1990, 358 p. (in Russ.).

Yashin Ya.I., Yashin A.Ya. Rossiyskiy khimicheskiy zhurnal, 2003, vol. 47, no. 1, pp. 64–79. (in Russ.).

Myul'khi Ye.P., Andryukhova M.V. IV natsional'naya nauchno-prakticheskaya konferentsiya «Aktual'nyye problemy nauki i praktiki v razlichnykh otraslyakh narodnogo khozyaystva». [IV national scientific and practical conference "Ac-tual problems of science and practice in various sectors of the national economy"]. Penza, 2021, pp. 39–42. (in Russ.).

Zuo Y., Chen H., Deng Y. Talanta, 2002, vol. 57, no. 2, pp. 307–316.

Lisichkin G.V., Serdan A.A., Kudryavtsev G.V., Staroverov S.M., Yuffa A.Ya. Modifitsirovannyye kremnezemy v sorbtsii, katalize i khromatografii. [Modified silicas in sorption, catalysis, and chromatography]. Moscow, 1986, 248 p. (in Russ.).

Drob' A.A., Vasiyarov G.G., Titova Ye.V., Staroverov S.M., Yakuba Yu.F., Guguchkina T.I. Sorbtsionnyye i khro-matograficheskiye protsessy, 2019, vol. 19, no. 2, pp. 179–186. DOI: 10.17308/sorpchrom.2019.19/736. (in Russ.).

Patent 1429016 (USSR). 27.02.1987. (in Russ.).

Patent 1077211 A3 (EP). 28.03.2001.

Patent 0083270 A1 (US). 01.05.2003.

Patent 097968 A (JA). 10.04.2001.

Wang R., Zhou W., Jiang X. Journal of Agricultural and Food Chemistry, 2008, vol. 56, pp. 2694–2701. DOI: 10.1021/jf0730338.

Rudakov O.B., Sedishev I.P. Izvestiya RAN. Seriya khimicheskaya, 2003, vol. 1, pp. 52–59. (in Russ.).

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.