SYNTHESIS, STRUCTURE AND PROPERTIES OF ORGANIC GELS BASED ON LARCH BARK TANNINS AND HY-DROLYSIS LIGNIN

UDC 547.992.3

Abstract

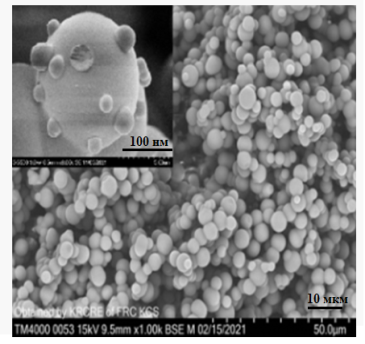

For the first time, tannin-lignin-formaldehyde and tannin-lignin-furfuryl organic gels were obtained on the basis of larch bark tannins and hydrolysis lignin by sol-gel condensation with formaldehyde and furfuryl alcohol. Their physico-chemical properties were studied by varying the content of lignin (from 5 to 30 wt%) and a fixed mass ratio of polyphenolic substances to the crosslinking reagent (1 : 1.5). With an increase in the lignin content the density of tannin-lignin formaldehyde gels decreases from 0.83 to 0.53 g/ cm3, and that of tannin-lignin-furfuryl gels is from 0.32 to 0.14 g / cm3. According to the FTIR data, the structures of tannin-lignin-formaldehyde and tannin-lignin-furfuryl gels are formed by aromatic fragments cross-linked with methylene and methylene-ether bridges. Scanning electron microscopy shows that the addition of appropriate amounts of lignin to tannins (up to 10 wt% when using formaldehyde and up to 20 wt% when using furfuryl alcohol) promotes the formation of gels with a more developed porous structure. In the case of tannin-lignin-formaldehyde gel, the specific surface area and sorption of methylene blue are 12 m2 / g and 43 mg / g and for tannin-lignin-furfuryl gel – 72 m2 / g and 114.5 mg/g, respectively. It was found that an increase in the lignin content in the gel composition over 20 wt.% is accompanied by the phase localization of lignin (precipitation), which reduces the strength of the resulting gel and reduces its specific surface area.

Downloads

Metrics

References

Aaltonen O., Jauhiainen O. Carbohydrate Polymers, 2009, vol. 75, pp. 125–129. DOI: 10.1016/j.carbpol.2008.07.008.

Tao Y., Endo M., Kaneko K. Recent Patents on Chemical Engineering, 2008, vol. 1, pp. 192–200. DOI: 10.2174/2211334710801030192.

Rey-Raap N., Calvo E.G., Menendez J.A., Arenillas A. Microporous and Mesoporous Materials, 2017, vol. 244, pp. 50–54. DOI: 10.1016/j.micromeso.2017.02.044.

Zhao S., Malfait W.J., Guerrero-Alburquerque N., Koebel M.M., Nystrçm G. Angew. Chem. Int. Ed., 2018, vol. 57, pp. 7580–7608. DOI: 10.1002/anie.201709014.

Celzard A., Fierro V., Amarat-Labat G., Szczurek A., Braghiroli F., Parmentier J., Pizzi A., Grishechko L.I., Kuz-netsov B.N. Boletín del Grupo Español del Carbón, 2012, vol. 26, pp. 2–7.

Rey-Raap N., Szczurek A. Fierro V., Celzard A., Menéndez J.A., Arenillas A. Industrial Crops and Products, 2016, vol. 82, pp. 100–106. DOI: 10.1016/j.indcrop.2015.12.001.

Grishechko L.I., Amaral-labat G., Szczurek A., Fierro V., Kuznetsov B.N., Pizzi A., Celzard A. Industrial Crops and Products, 2013, vol. 41, pp. 347-355. DOI: 10.1016/j.indcrop.2012.04.052.

Elkhatat A.M., Al-Muhtaseb S.A. Advanced Materials, 2011, vol. 23, pp. 2887–2903. DOI: 10.1002/adma.201100283.

Arenillas A., Menéndez J.A., Reichenauer G., Celzard A., Fierro V., Josй F., Hodar M., Bailόn-Garcia E., Job N. Organ-ic and Carbon Gels. From Laboratory Synthesis to Applications, 2019. 195 p. DOI: 10.1007/978-3-030-13897-4.

Mikova N.M., Levdanskiy V.А., Skwortsova G.P., Zhizhaev А.М., Lutoshkin M.A., Chesnokov N.V., Kuznetsov B.N. Biomass Conversion and Biorefinery, 2019. DOI: 10.1007/s13399-019-00561-8.

Amaral-Labat G., Grishechko L.I., Fierro V., Kuznetsov B.N., Pizzi A., Celzard A. Biomass and bioenergy, 2013, vol. 56, pp. 437–445. DOI: 10.1016/j.biombioe.2013.06.001.

Vassilev S.V., Baxter D., Andersen L.K., Vassileva C.G. Fuel, 2010, vol. 89, no. 5, pp. 913–933. DOI: 10.1016/j.fuel.2009.10.022.

Pizzi A. Tannins: Major Sources, Properties and Applications. Monomers, Polymers and Composites from renewable re-sources // Eds M. N. Belgacem, A. Gandini, Elsevier, 2008, pp. 179–199.

Gordiyenko I.I., Fedorova T.Ye., Ivanova S.Z., Babkin V.A. Khimiya rastitel'nogo syr'ya, 2008, no. 2, pp. 35–38. (in Russ.).

Sarkanen K.V. Ligniny (struktura, svoystva i reaktsii). [Lignins (structure, properties and reactions)]. Ed. K.V. Sarkanen, K.H. Ludwig. Moscow, 1975, 629 p. (in Russ.).

Aegerter M.A., Leventis N., Koebel M.M. Aerogels Handbook. Springer Science, 2011. 916 p. DOI: 10.1007/978-1-4419-7589-8.

Wu D., Fu R. J. Porous Mater, 2005, vol. 12, pp. 311–316.

Fathy N.A., Rizk M.S., Awad R.M.S. J. Anal Appl Pyrolysis, 2016, vol. 119, pp. 60–68. DOI: 10.1016/j.jaap.2016.03.017.

Markelov D.A., Nitsak O.V., Gerashchenko I.I. Khimiko-farmatsevticheskiy zhurnal, 2008, vol. 42(7), pp. 30–33. (in Russ.).

Szczurek A., Fierro V., Thébault M., Pizzi A., Celzard A. European Polymer Journal, 2016, vol. 78, pp. 195–212. DOI: 10.1016/J.EURPOLYMJ.2016.03.037.

Kraiwattanawong K., Mukai S.R., Tamon H., Lothongkum A.W. Microporous and Mesoporous Materials, 2007, vol. 98, pp. 258–266. DOI: 10.1016/j.micromeso.2006.09.007.

Akerholm M., Salmen L. Polymer, 2001, vol. 42, pp. 963–969.

Szczurek A., Amaral-Labat G., Fierro V., Pizzi A., Masson E., Celzard A. Carbon, 2011, vol. 49, pp. 2773–2784. DOI: 10.1016/j.carbon.2011.03.007.

Fathya N.A., Rizk M.S., Awad Reham M.S. J. Anal Appl Pyrolysis, 2016, vol. 119, pp. 60–68. DOI: 10.1016/j.jaap.2016.03.017.

Jirglová H., Pérez-Cadenas A.F., Maldonado-Hódar F.J. Langmuir, 2009, vol. 25(4), pp. 2461–2466. DOI: 10.1021/la803200b.

Li W-C., Lu A-H., Guo S-C. Carbon, 2001, vol. 39, pp. 1989–1994. DOI: 10.1016/S0008-6223(01)00029-X.

Girgis B.S., El-Sherif I.Y., Attia A.A., Fathy N.A. J. Non Cryst. Solids., 2012, vol. 358(4), pp. 741–747. DOI: 10.1016/j.jnoncrysol.2011.12.004.

Gallegos-Suarez E., Perez-Cadenas A.F., Maldonado-Hodar F.J., Carrasco-Marin F. Chemical Engineering Journal, 2012, vol. 181–182, pp. 851–855. DOI: 10.1016/j.cej.2011.12.002.

Choura M., Belgacem N.M., Gandini A. Macromolecules, 1996, vol. 29, pp. 3839–3850. DOI: 10.1021/ma951522f.

Tannet R., Schwan M., Ratke L. J. of Supercritical Fluids, 2015, vol. 106, pp. 57–61. DOI: 10.1016/j.supflu.2015.06.021.

Al-Muhtased S.B., Ritter J.A. Advanced Materials, 2003, vol. 15, pp. 101–114. DOI: 10.1002/adma.200390020.

Amaral-Labat G., Szczurek A., Fierro V., Pizzi A., Celzard A. Science and Technology of Advanced Materials, 2013, vol. 14, issue 1. Article 015001. DOI: 10.1088/1468-6996/14/1/015001.

Feng Chen, Min Lijuan Wang, Jian Li. BioResources, 2011, vol. 6, issue 2, pp. 1262–1272. DOI: 10.15376/biores.6.2.1262-127.

Wu D., Fu R. Micropore and Mesopore Materials, 2006, vol. 96, pp. 115–120. DOI: 10.1016/j.micromeso.2006.06.022.

Wu D., Fu R., Dresselhaus M.S., Dresselhaus G. Carbon, 2006, vol. 44, pp. 675–681. DOI: 10.1016/j.carbon.2005.09.022.

Grishechko L.I., Amaral-Labat G., Szczurek A., Fierro V., Kuznetsov B.N., Celzard A. Micropor Mesopor Mater., 2013, vol. 168, pp. 19–29. DOI: 10.1016/j.micromeso.2012.09.024.

Wang F., Yao L.F., Shen J. Guan D.Y., Fang Zh. Adv. Mater. Res., 2014, vol. 941–944, pp. 450–453. DOI: 10.4028/www.scientific.net/AMR.941-944.450.

Sing R.S.W., Everett D.H., Haul R.A.W., Moscou L., Pierotti R.A.,Rouquerol J., Siemieniewska T. Pure Appl. Chem., 1985, vol. 57, pp. 603–619.

Reshetnikov V.I. Khimiko-farmatsevticheskiy zhurnal, 2003, vol. 37, no. 5, pp. 28–32. (in Russ.).

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.