PREPARATION OF NANOCELLULOSE FROM NON-WOOD PLANT RAW MATERIALS

Abstract

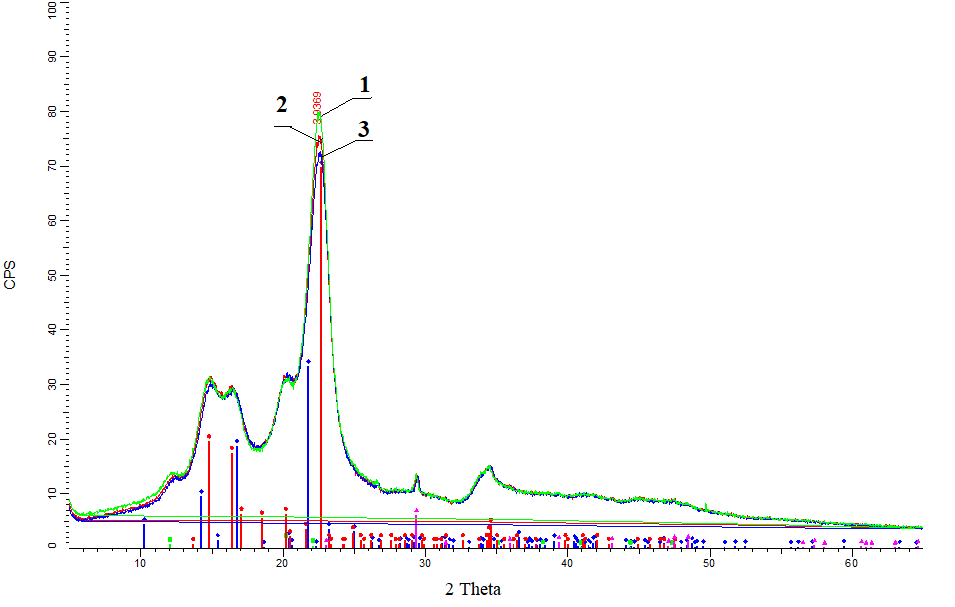

The purpose of this work was to study the possibility of obtaining nanocellulose (NC) by ultrasonic (US) processing in the medium of liquid nitrogen (LN) powdered cellulose. To achieve this goal, it was necessary to determine the effect of the time of ultrasonic treatment in the medium of LN on the dispersed composition, crystallinity index and degree of polymerization (DP) of cellulose samples. Studies were performed using a powder X-ray diffractometer, a laser particle analyzer, and a scanning and transmission electron microscope. DP of cellulose was determined by the viscosity of its solution in cadoxene by the standard method. It has been found that cryogenic grinding of flax cellulose samples does not lead to significant changes in its structural modification and degree of crystallinity, which indicates the high resistance of this material to such effects. However, ultrasonic exposure in the medium of LN with the subsequent treatment with 25%, 45%, 65% H2SO4 allows to obtain cellulose nanospheres with a diameter of 48 to 437 nm and a yield of up to 40%. Unlike other types of nanoparticles (nanofibrillary, nanocrystalline cellulose), cellulose nanospheres have a larger surface area, which opens up the possibility of their effective use for the modification of composite materials.

Downloads

References

Dufresne A. Nanocellulose from nature to High Performance Tailored Materials, Berlin; Germany, 2012, 477 p.

Patent 2534338 (GB). 2016.

Patent 4374702 (US). 1983.

Patent 8945346В2 (US). 2015.

Patent 2505545 (RU). 2014. (in Russ.).

Patent 2530067 (RU). 2014. (in Russ.).

Patent 2494109 (РФ). 2012. (in Russ.).

Patent 067942 (WO). 2008.

Petrov V.A., Aver'yanova N.V., Gibadullin M.R., Khammatov I.A., Kametova K.R., Dobrynin A.B. Vestnik Ka-zanskogo tekhnologicheskogo universiteta, 2013, vol. 16, no. 14, pp. 83–85. (in Russ.).

Patent 000392 (NO). 2008.

Rebouillat S., Pla F. Journal of Biomaterials and Nanobiotechnology, 2013, vol. 4, no. 2, pp. 165–188, DOI: 10.4236/jbnb.2013.42022.

Rodriguez N., Thielemans W., Dufresne A. Cellulose, 2006, vol. 13, no. 3, pp. 261–270, DOI: 10.1007/s10570-005-9039-7.

Lotosh V.Ye., Lotosh L.S. Pererabotka otkhodov prirodopol'zovaniya. [Recycling of natural resources]. Yekaterinburg, 2007, 503 p. (in Russ.).

Patent 2343240 (RU). 2009. (in Russ.).

Rogovin Z.A. Tsellyuloza i yeyo proizvodnyye. [Cellulose and its derivatives]. Moscow, 1974, 499 p. (in Russ.).

GOST 25438-82. Tsellyuloza dlya khimicheskoy pererabotki. [GOST 25438-82. Cellulose for chemical processing]. Moscow, 1989, 15 p. (in Russ.).

Lin N., Huang G. Nanoscale, 2012, vol. 4, no. 11, pp. 3274–3294, DOI: 10.1039/c2nr30260h.

Zakharov A.G., Voronova M.I., Radugin M.V., Lebedeva T.N., Trutnev N.S. Khimiya rastitel'nogo syr'ya, 2010, no. 1, pp. 13–19. (in Russ.).

Astruc J. Carbohydrate Polymers, 2017, vol. 178, pp. 352–359, DOI: 10.1016/j.carbpol.2017.08.138

Ioelovich M. American Journal of Nanoscience and Nanotechnology, 2013, vol. 1, no. 1, pp. 41–45, DOI: 10.11648/j.nano.20130101.18.

Li X. Polym. Sci., 2001, vol. 19, no. 3, pp. 291–296.

Copyright (c) 2019 Khimiia rastitel'nogo syr'ia (Chemistry of plant raw material)

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.