SYNTHESIS AND STUDY OF THE PROPERTIES OF XEROGELS DERIVED FROM SULFATED PINE ETHANOL LIGNIN

UDC 547.992.3

Abstract

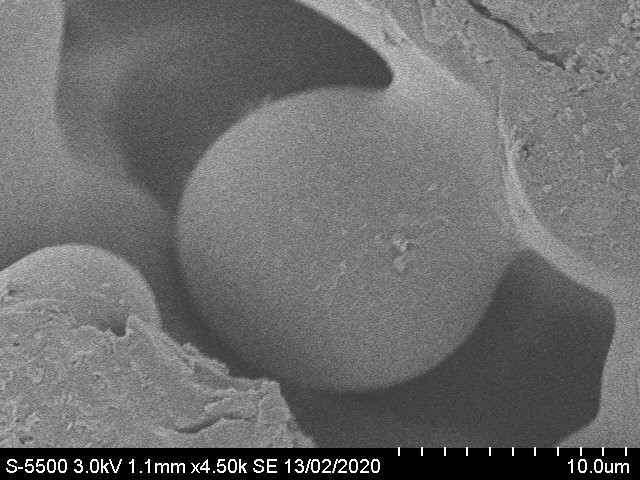

Organic xerogels based on lignin and tannins isolated from pine bark and wood were first obtained by condensation with formaldehyde and furfuryl alcohol in the presence of hydrochloric acid. The use of pine sulfated ethanol lignin made it possible for the first time to obtain sulfur-containing (up to 1.3% wt.) lignin-(tannin)-formaldehyde and lignin-(tannin)-furfuryl xerogels. The density of the obtained gels increases with the addition of tannins to lignin and varies in the range 0.13–0.39 g/cm3. Xerogels synthesized by condensation with furfuryl alcohol are stronger than those obtained using formaldehyde. The presence of sulfur in xerogels was confirmed by elemental and chemical analysis and IR spectroscopy. It was shown by scanning electron microscopy, that lignin-formaldehyde xerogels are formed from large polymer chains, consisting of interconnected aggregates of micron-sized particles and have large pores. The addition of tannins to the polycondensation system is accompanied by the formation of a more compact spatially crosslinked gel structure. BET method showed that all xerogels have low porosity, and lignin-furfuryl samples have a larger average pore diameter (7.2–14.5 nm) compared to lignin-formaldehyde samples (3.03–6.80 nm).

Downloads

References

Rey-Raap N., Szczurek A., Fierro V., Menéndez J.A., Arenillas A., Celzard A. J. Colloid Interface Sci., 2015, vol. 456, pp. 138–144. DOI: 10.1016/j.jcis.2015.06.024.

Pierre A.C., Pajonk G.M. Chemical Reviews, 2002, vol. 102, pp. 4243–4265. DOI: 10.1021/cr0101306.

Kraiwattanawong K., Tamon H., Praserthdam P. Micropor Mesopor Mater., 2011, vol. 138 (1–3), pp. 8–16. DOI: 10.1016/j.micromeso.2010.10.001.

Job N., The´ry A., Pirard R., Marien J., Kocon L., Rouzaud J.-N., Be´guin F. Carbon, 2005, vol. 43 (12), pp. 2481–2494. DOI: 10.1016/j.carbon.2005.04.031.

Chen Ch., Kennel E.B., Stiller A.H., Stansberry P.G., Zondlo J.W. Carbon, 2006, vol. 44, pp. 1535–1543. DOI: 10.1016/j.carbon.2005.12.021.

Amaral-Labat G., Szczurek A., Fierro V., Pizzi A., Celzard A. Science and Technology of Advanced Materials, 2013, vol. 14(1), 015001. DOI: 10.1088/1468-6996/14/1/015001.

Stewart D. Indust. Crops and Products, 2008, vol. 27, pp. 202–207. DOI: 10.1016/j.indcrop.2007.07.008.

Karaaslan M.A., Kadla J.F., Ko F.K. Lignin in Polymer Composites, 2016, pp. 67–93. DOI: 10.1016/B978-0-323-35565-0.00005-9.

Chen F., Li J. Advanced Materials Research, 2010, vol. 113–116, pp. 1837–1840. DOI: 10.4028/www.scientific.net/AMR.113-116.1837.

Tamon H., Ishizaka H., Mikami M., Okazaki M. Carbon, 1997, vol. 35(6), pp. 791–796. DOI: 10.1016/S0008-6223(97)00024-9.

Chen F., Xu M., Wang L., Li J. Bioresources, 2011, vol. 6, pp. 1261–1272.

Grishechko L.I., Amaral-Labat G., Szczurek A., Fierro V., Kuznetsov B.N., Celzard A. Micropor Mesopor Mater., 2013, vol. 168, pp. 19–29. DOI: 10.1016/j.micromeso.2012.09.024.

Grishechko L.I., Amaral-Labat G., Szczurek A., Fierro V., Kuznetsov B.N., Pizzi A., Celzard A. Indust. Crops and Products, 2013, vol. 41, pp. 347–355. DOI: 10.1016/j.indcrop.2012.04.052.

Mikova N.M., Levdanskiy V.А., Skwortsova G.P., Zhizhaev А.М., Lutoshkin M.A., Chesnokov N.V., Kuz-netsov B.N. Biomass Conversion and Biorefinery, 2020. DOI: 10.1007/s13399-019-00561-8.

Nishida M., Uraki Y. Bioresour. Technol., 2003, vol. 88, pp. 81–83. DOI: 10.1016/S0960-8524(02)00264-X.

Passauer L. Holzforschung. ACS Symposium Series, 2012, vol. 1107, pp. 211–228. DOI: 10.1021/bk-2012-1107.ch011.

Perez-Cantu L., Liebner F., Smirnova I. Micropor Mesopor Mater., 2014, vol. 195, pp. 303–310. DOI: 10.1016/j.micromeso.2014.04.018.

Thakur V.K., Thakur M.K. International Journal of Biological Macromolecules, 2015, vol. 72, pp. 834–847. DOI: 10.1016/j.ijbiomac.2014.09.044.

Seo J., Park H., Shin K., Baeck S.H., Rhym Y., Shim S.E. Carbon, 2014, vol. 76, pp. 357–367. DOI: 10.1016/j.carbon.2014.04.087.

Malutan T., Nici R., Popa V.I. BioResources, 2008, vol. 3(1), pp. 13–20. DOI: 10.15376/biores.3.1.13-20.

Kuznetsov B.N., Vasilyeva N.Yu., Kazachenko A.S., Levdansky V.A., Kondrasenko A.A., Malyar Yu.N., Skvort-sova G.P., Lutoshkin M.A. Wood science and technology, 2020, vol. 54, pp. 365–381. DOI: 10.1007/s00226-020-01157-6.

Lee Y.J., Jung J.C., Park S., Seo J.G., Baeck S.H., Yoon J.R., Yi J. et al. Current Applied Physics., 2010, vol. 10 (3), pp. 947–951. DOI: 10.1016/j.cap.2009.11.078.

Machado B.F., Gomes H.T., Serp P., Kalck P., Figueiredo J.L., Faria J.L. Catalysis Today, 2010, vol. 149, pp. 358–364. DOI: 10.1016/j.cattod.2009.06.016.

Feinle A., Hüsing N. J. Supercritical Fluids, 2015, vol. 106, pp. 2–6. DOI: 10.1016/j.supflu.2015.07.015.

Rey-Raap N., Szczurek A., Fierro V., Celzard A., Menéndez J.A., Arenillas A. Indust. Crops and Products, 2016, vol. 82, pp. 100–106. DOI: 10.1016/j.indcrop.2015.12.001.

Kicin´ski W., Szala M., Bystrzejewsk M. Carbon, 2014, vol. 68, pp. 1–32. DOI: 10.1016/j.carbon.2013.11.004.

Kuznetsov B.N, Vasilyeva N.Yu., Kazachenko A.S., Skvortsova G.P., Levdansky V.A., Lutoshkin M.A. J. Sib. Fed. Univ. Chem., 2018, vol. II(I), pp. 122–130. DOI: 10.17516/1998-2836-0170. (in Russ.).

Cheronis N.D., Ma T.S. Mikro- i polumikrometody organicheskogo funktsional'nogo analiza. [Micro- and semi-micromethods of organic functional analysis]. Moscow, 1973, 576 p. (in Russ.).

Gregg S., Sing K. Adsorbtsiya. Udel'naya poverkhnost'. Poristost'. [Adsorption. Specific surface area. Porosity]. Mos-cow, 1984, 306 p. (in Russ.).

Lignin and lignans: advances in chemistry, eds. C. Heitner, D. Dimmel, J. Schmidt. CRC. Press: Taylor and Francis Group, 2010, 683 p. DOI: 10.1201/EBK1574444865.

Lochab B., Shukla S., Varma I.K. RSC Adv., 2014, vol. 4, pp. 21712–21752. DOI: 10.1039/C4RA00181H.

Rey-Raap N., Calvo E.G., Menendez J.A., Arenillas A. Micropor Mesopor Mater., 2017, vol. 244, pp. 50–54. DOI: 10.1016/j/micromeso.2017.02.044.

Copyright (c) 2021 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.