INVESTIGATION OF ACID-CATALYSED CONVERSION OF LIGNOCELLULOSIC BIOMASS BY 1H NMR SPECTROSCOPY

UDC 661.728.892:537.635

Abstract

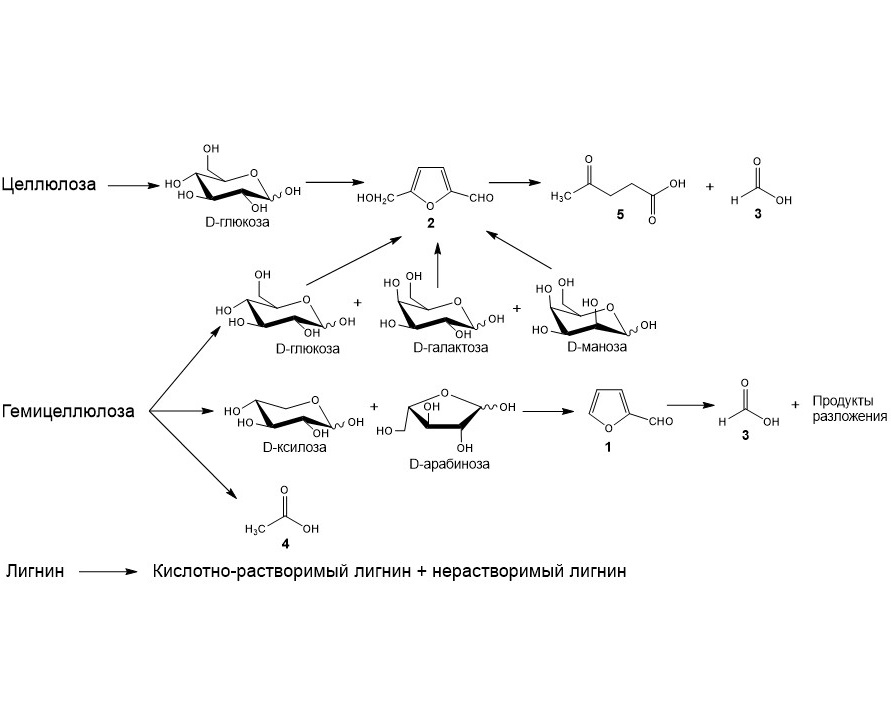

The composition of the products of acid-catalyzed conversion of plant materials was studied using 1H NMR spectroscopy. CH3SO3H was used as an acid catalyst. A procedure was developed for quantitative determination of the content of such compounds as glucose, furfural, 5-hydroxymethylfurfural, formic, acetic, glycolic and levulinic acids in reaction mixtures. This was carried out on the basis of the integrated intensities of the corresponding signals in 1H NMR spectra using CH3SO3H as an internal standard. Birch, oak and pine wood samples, as well as agricultural waste, were selected as the starting plant materials for the acid-catalyzed conversion. Hydrolysis was carried out in a 3.5% solution of methanesulfonic acid in D2O at temperatures from 120 °C to 160 °C in sealed glass ampoules. The use of D2O allowed NMR studies of the reaction products to be carried out without additional sample preparation. The results obtained on the basis of 1H NMR spectra showed that the ratio of hydrolysis products depends on the ratio of cellulose and hemicellulose in the feedstock. When carrying out the acid-catalyzed conversion process at different tem-peratures (120 °C, 140 °C, 160 °C), the effect of temperature on the composition and yield of the reaction products was studied. It was revealed that with increasing temperature the amount of mon-osaccharides decreases, while the yield of formic and acetic acids increases. The maximum yield of levulinic acid and furfural is observed at a temperature of 140 °C. These data emphasize the effect of temperature conditions on the efficiency of the process for optimizing the production of the de-sired products, which may be of great importance for further research in the field of conversion of plant materials into useful chemicals.

Downloads

References

Corma A., Iborra S., Velty A. Chemical Reviews, 2007, vol. 107, pp. 2411–2502. https://doi.org/10.1021/cr050989d.

Singh N., Singhania R.R., Nigam P.S., Dong C.-D., Patel A.K., Puri M. Bioresource Technology, 2022, vol. 344B, 126415. https://doi.org/10.1016/j.biortech.2021.126415.

Alonso D.M., Bond J.Q., Dumesic J.A. Green Chemistry, 2010, vol. 12, pp. 1493–1513. https://doi.org/10.1039/C004654J.

Khemthong P., Yimsukanan C., Narkkun T., Srifa A., Witoon T., Pongchaiphol S., Kiatphuengporn S., Faungnawakij K. Biomass and Bioenergy, 2021, vol. 148, 106033. https://doi.org/10.1016/j.biombioe.2021.106033.

Pattnaik F., Tripathi S., Patra B., Nanda S., Kumar V., Dalai A., Naik S. Environmental Chemistry Letters, 2021, vol. 19, no 6, pp. 4119–4137. https://doi.org/10.1007/s10311-021-01284-x.

Cousin E., Namhaed K., Pérès Y., Cognet P., Delmas M., Hermansyah H., Gozan M., Alaba P.A., Aroua M.K. Sci-ence of The Total Environment, 2022, vol. 847, 157599. https://doi.org/10.1016/j.scitotenv.2022.157599.

Murzin D., Holmbom B. Catalysis for the Conversion of Biomass and Its Derivatives. Berlin, 2013, pp. 183–211. https://doi.org/10.1201/b18526-5.

Davies S.M., Linforth R.S., Wilkinson S.J., Katherine A.S., David J.C. Biotechnol Biofuels, 2011, vol. 4, 28. https://doi.org/10.1186/1754-6834-4-28.

Rackemann D.W., Bartley J.P., Doherty W.O.S. Industrial Crops and Products, 2014, vol. 52, pp. 46–57. https://doi.org/10.1016/j.indcrop.2013.10.026.

Altaner C.M., Saake B. Cellulose, 2016, vol. 23, pp. 1003–1010. https://doi.org/10.1007/s10570-015-0841-6.

Efremov A.A., Pervyshina G.G., Kuznetsov B.N. Khimiya prirodnykh soyedineniy, 1998, no. 2, pp. 226–230. (in Russ.).

Boltovskiy V.S. Khimiya rastitel'nogo syr'ya, 2014, no. 2, pp. 5–12. https://doi.org/10.14258/jcprm.1402005. (in Russ.).

Girisuta B., Dussan K., Haverty D., Leahy J.J., Hayes M.H.B. Chemical Engineering Journal, 2013, vol. 217, pp. 61–70. https://doi.org/10.1016/j.cej.2012.11.094.

Kostryukov S.G., Malov N.A., Masterova Yu.Yu., Matyakubov Kh.B., Konushkin I.A., Savrasov K.V., Pynen-kov A.A., Khluchina N.A. Russian Journal of Bioorganic Chemistry, 2023, vol. 49, no. 7, pp. 1628–1635. https://doi.org/10.1134/s106816202307083x.

Kostryukov S.G., Mat'yakubov Kh.B., Masterova Yu.Yu., Kozlov A.Sh., Pryanichnikova M.K., Pynenkov A.A., Khluchina N.A. Zhurnal analiticheskoy khimii, 2023, vol. 78, no. 6, pp. 496–506. https://doi.org/10.31857/S0044450223040102. (in Russ.); (Kostryukov S.G., Matyakubov H.B., Masterova Yu.Yu., Kozlov A.Sh., Pryanichnikova M.K., Pynenkov A.A., Khluchina N.A. Journal of Analytical Chemistry. 2023, vol. 78, no. 6, pp. 718–727. https://doi.org/10.1134/s1061934823040093).

Liu S., Zhu Y., Liao Y., Wang H., Liu Q., Ma L., Wang C. Applications in Energy and Combustion Science, 2022, vol. 10, 100062. https://doi.org/10.1016/j.jaecs.2022.100062.

Copyright (c) 2025 Chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.